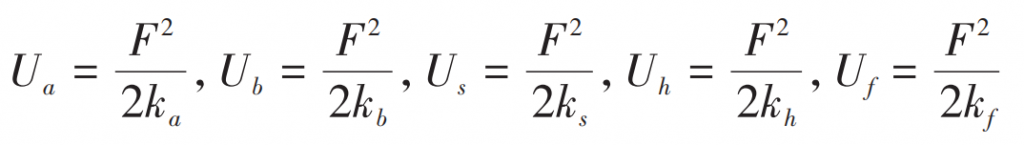

The basic idea of determining the meshing stiffness of spur gears is to calculate the actual tooth contact deformation at discrete rolling positions, and then determine the accumulated potential energy during spur gear meshing. The research shows that the total potential energy consists of five components, namely, contact potential energy Uh, bending potential energy Ub, shear potential energy Us, compression potential energy Ua, and gear base potential energy Uf, which correspond to Hertz contact stiffness kh, bending stiffness kb, shear stiffness ks, axial compression stiffness ka, and gear base stiffness kf, respectively. From elasticity, it can be concluded that:

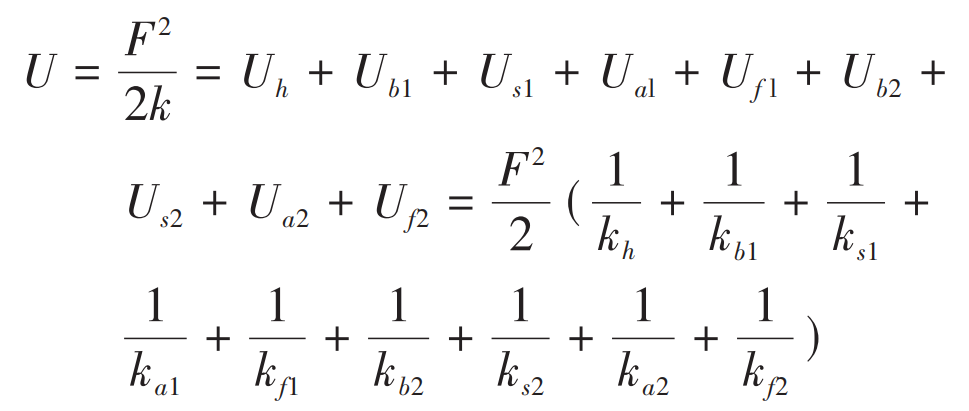

In the formula, F is the meshing force between the teeth. The total potential energy stored in a pair of spur gear meshing teeth can be expressed as the sum of the potential energy of each part of the driving gear and the passive gear, namely:

In the formula, the subscripts 1 and 2 represent the driving gear and the passive gear, respectively.

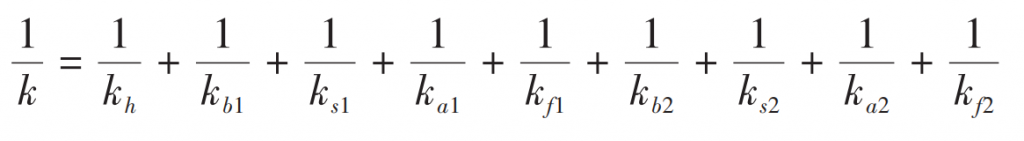

There are different meshing intervals when spur gear pairs mesh. The stiffness of the single tooth meshing zone can be expressed as:

In the formula, the subscripts 1 and 2 respectively represent the driving gear and the passive gear during the meshing process.

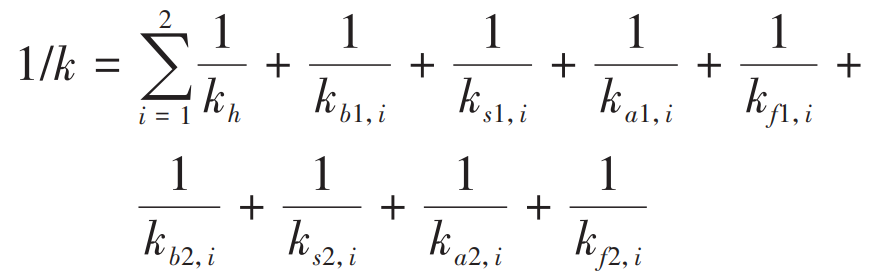

The stiffness of the double tooth meshing zone can be expressed as:

In the formula, i=1 and 2 respectively represent the first and second pairs of teeth during the meshing process of the spur gear.

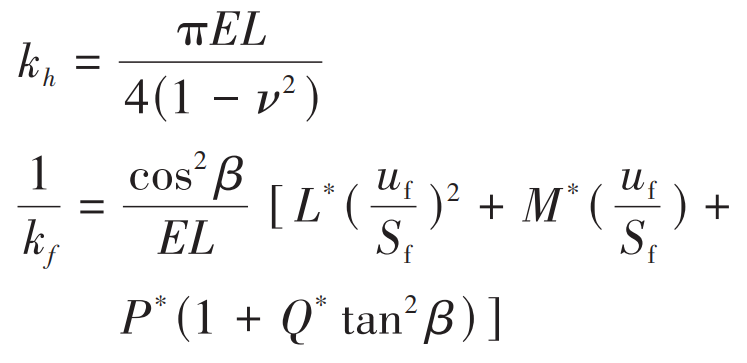

Hertz contact stiffness kh and tooth base stiffness kf are usually calculated by the formula, namely:

In the formula, E is the elastic modulus; L is the tooth width; ν Is Poisson’s ratio.