Through gene analysis and basic performance experiment of automobile gear materials, it is very important to master the basic parameters and strength characteristics of materials for numerical simulation of heat treatment and prediction of heat treatment deformation and strength. Due to the diffusion process of carburizing and nitriding in heat treatment, temperature change, phase transformation and stress-strain are the dynamic processes of multi field coupling behavior. Mastering the dynamic process of multi field coupling is the key to obtain the optimal heat treatment process of automobile gears. For example, automotive gear steel will produce phase transformation plasticity during heat treatment, and its behavior will directly affect the deformation and residual stress of automotive gear after heat treatment.

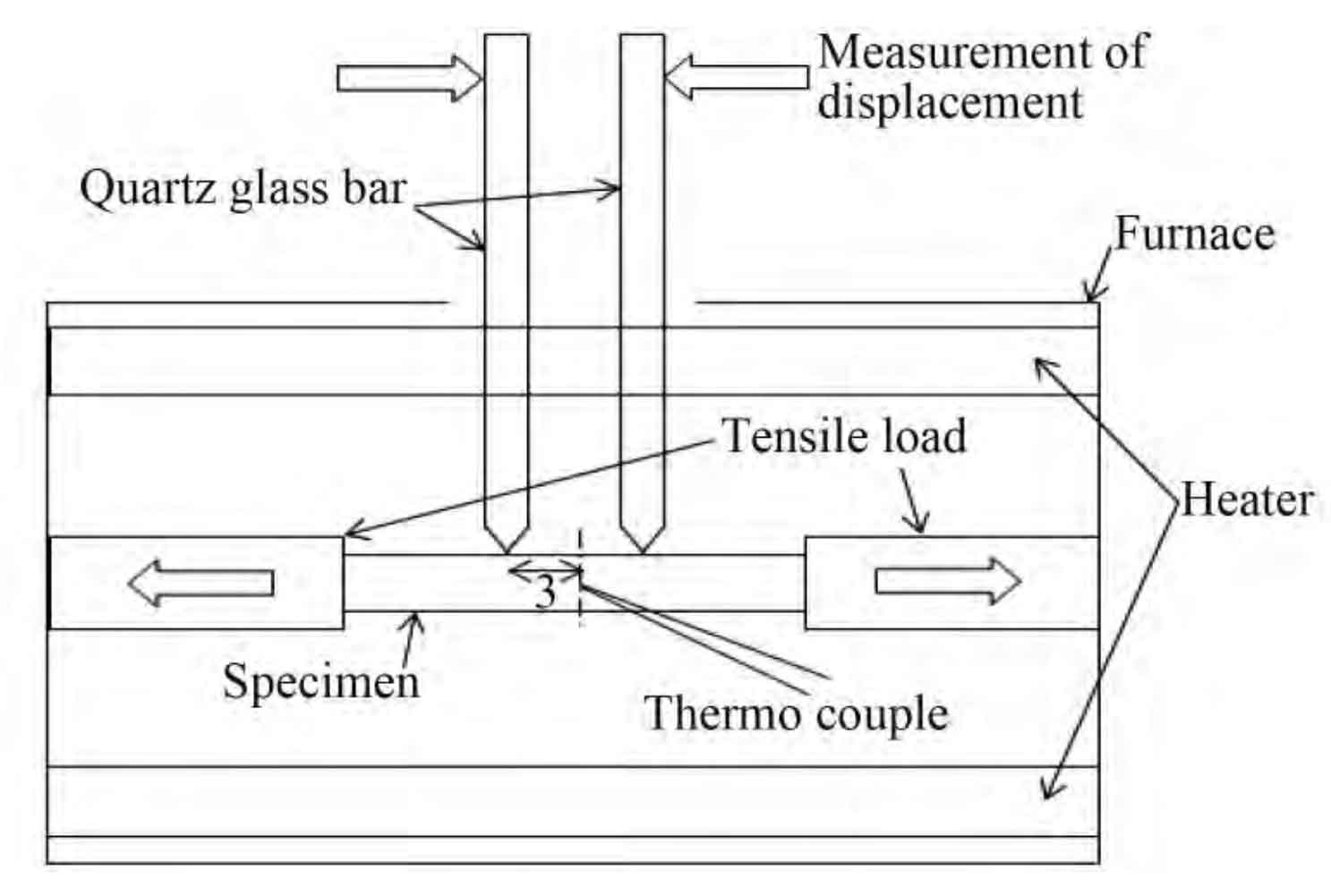

Therefore, it is often difficult to predict and control the heat treatment deformation of automobile gears without considering the phase transformation plasticity in the heat treatment simulation of automobile gears, and it is impossible to determine the machining allowance before heat treatment. Figure 1 shows the general situation of phase transformation plasticity test of automobile gear steel during heat treatment.

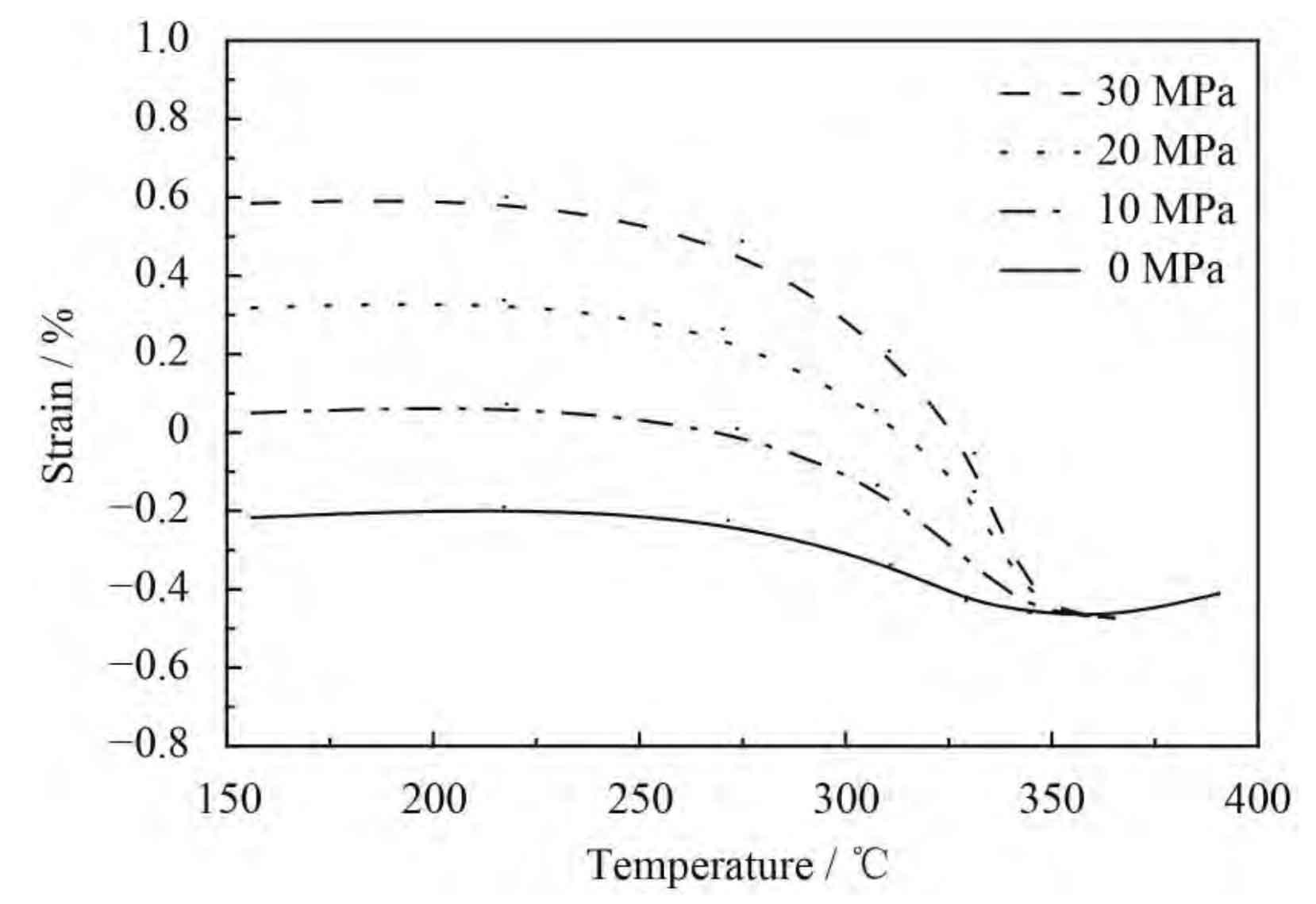

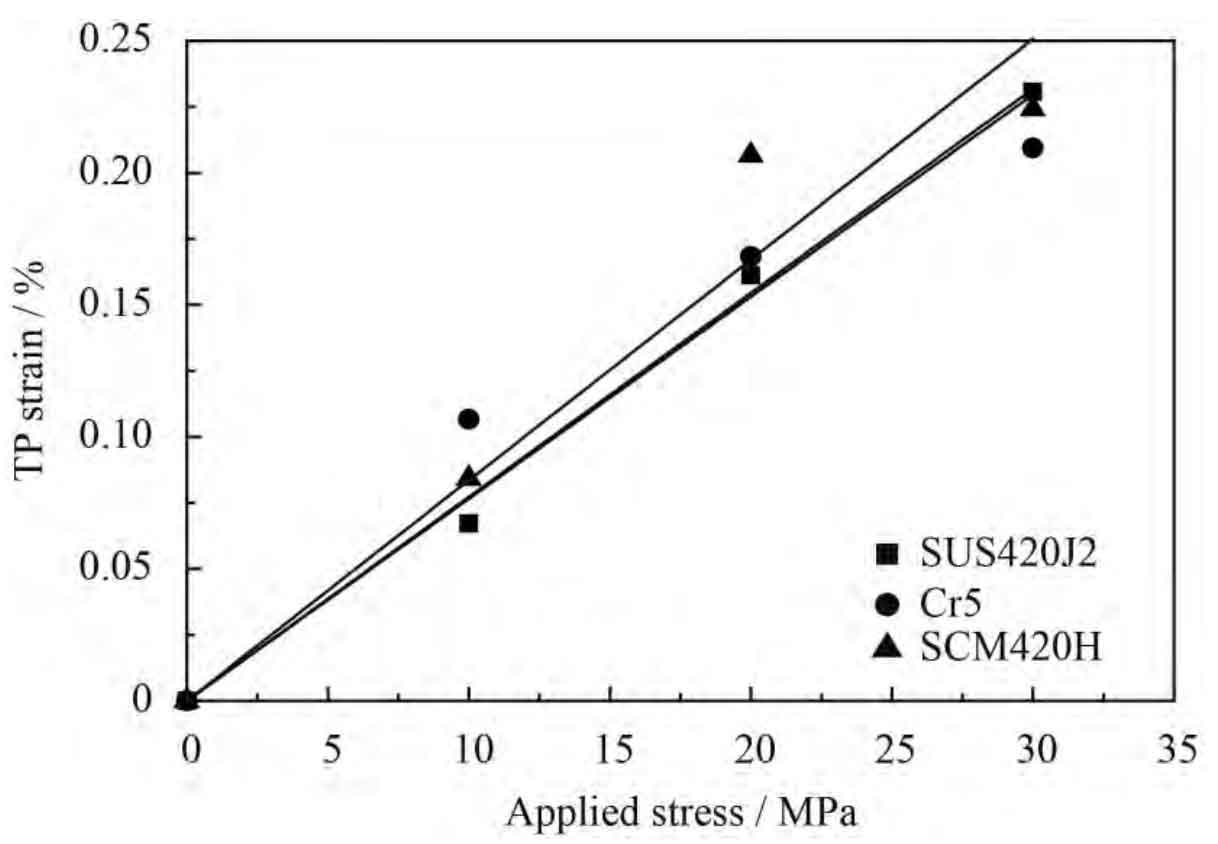

According to the continuum thermodynamics theory and phase transformation thermodynamics theory, ZHY gear has developed the heat treatment numerical simulation cosmap (computer simulation of manufacturing process) software, which can numerically simulate the heat treatment processes such as quenching, carburizing, nitriding and local heating or cooling of automobile gears. Fig. 2 is the strain temperature curve of the measuring point of SCM420H sample under different tensile stress loads obtained by simulation, and Fig. 3 is the transformation plasticity coefficient obtained according to the transformation plasticity theory and experiment.