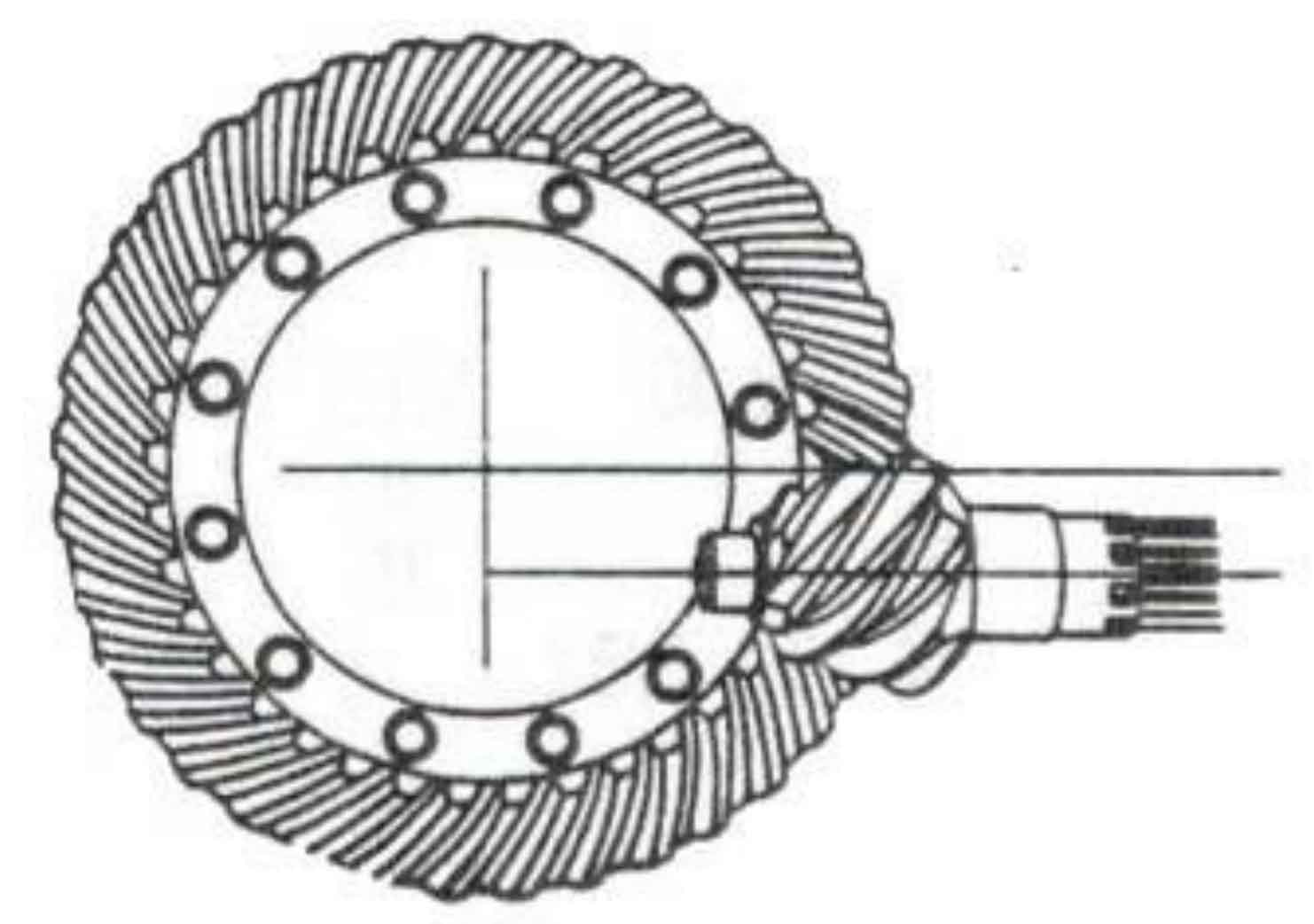

Figure (a) shows gleason#116 hypoid gear processing machine tool. The machine tool obtains the convex or concave surface of the gear by cutting the material on the workpiece. The specific working principle is shown in figure (b). The cutter head 5 rotates around the central axis e at a certain speed, and its rotation speed ω (t) It is related to the speed of gear processing, and has nothing to do with the rotation speed of workpiece 7 or shaking table 1. The cutter head 5 and the shaking table 1 are connected through the cutter tilting mechanism 4, the cutter rotating mechanism 3 and the eccentric wheel 2, so as to adjust the distance between the cutter head axis E and the shaking table axis A, as well as the relative angle between the two axes, so as to obtain the midpoint spiral angle that meets the design requirements. The rotation speed ratio between shaking table 1 and workpiece 7 is controlled by gear and shaft mechanism, and the relationship between them can be established through coordinate transformation. The gear surface machined by the generating method is the envelope surface of the generating gear surface formed by the tool on the cutter head, and the points on the gear surface are the points formed in the machining process that are tangent to the generating gear surface. The necessary condition for the existence of this envelope surface is to satisfy the meshing equation, which can be expressed as that the normal vector of the production wheel at the meshing point is perpendicular to the relative velocity of the production wheel and the workpiece at the meshing point.

The coordinate transformation process is to determine the envelope point of any point on the tool in the machine coordinate system m s rigidly connected with the machine tool, and the coordinates in the corresponding workpiece coordinate system w s. Homogeneous coordinates can easily express vector translation and rotation. HFT hypoid gear processing method is one of the most widely used spiral bevel gear processing methods, that is, the pinion adopts the generation method, the big gear adopts the forming method, and the forming method processing can be regarded as a special case of the generation method processing. Therefore, we first study the surface formed by the pinion tool in the cutter head coordinate system.