Swing head inclination γ It refers to the included angle between the cone die axis and the fuselage axis. Swing head inclination γ The influence of the size of on the process is mainly reflected in the influence on the rotary rolling force, rotary head torque and the depth of plastic deformation zone, that is, the tonnage power of rotary rolling equipment and the uniformity of metal flow and deformation. These are two aspects that should be considered in determining the tilt angle of the swing head.

1.Swing head inclination γ Effect on rotary forging force P and torque MR

Because the rotary forging of bevel gear is similar to the rotary forging of thick cylinder, the former can be simplified to the latter for analysis. The rotary rolling force and rotary rolling moment of Huizhou thick cylinder are analyzed. It is proved that the rolling pressure is related to the contact area ratio and stress state coefficient λ And stress state coefficient n σ In direct proportion. and λ And n σ Is along with γ It increases and decreases, so γ The larger the rolling force, the smaller the rolling force, and the more labor-saving; At the same time, the rotary rolling torque also varies with the inclination of the rotary head γ Decreased with the increase of.

In order to save labor and reduce torque, that is, reduce power, the tilt angle of swing head γ The bigger the better. It is also pointed out that the inclination of swing head γ The influence is great within 0-3 °; At 3 ° – 6 °, the change of rotary rolling inclination has a certain effect; And when γ> At 6 °, the change of rotary rolling angle has little effect on rotary rolling force and rotary head torque. This is also the swing head inclination of the swing rolling machine manufactured at present γ< At 6 °, most are γ ≤ 3 °.

2.Swing head inclination γ Influence on deformation

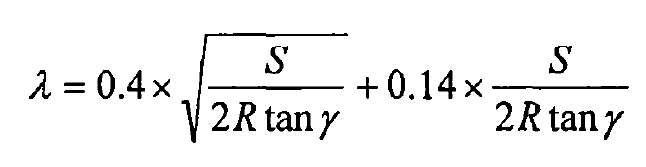

In the process of rotary forging, the contact surface between the cone die and the workpiece is the part directly bearing the die pressure and the active deformation area of the plastic deformation area. The larger the area, the greater the depth of the plastic deformation area, the more uniform the deformation and the higher the contact area ratio λ The size of can reflect the uniformity of workpiece deformation to a certain extent. Therefore, we can discuss the swing head inclination γ Contact area ratio λ To investigate the tilt angle of swing head γ Influence on deformation uniformity.

According to the derived formula of contact area ratio:

It can be seen that the tilt angle of swing head γ The smaller, the smaller the contact area ratio λ The bigger. So, swing head inclination γ The smaller, the more uniform the deformation of the workpiece; conversely, γ The larger the, the more uneven the deformation of the workpiece.

3.Swing head inclination in cold rotary forging precision forming of bevel gear γ Determination of

Based on the above analysis, the following conclusions can be drawn: swing angle γ It affects the rotary rolling force, rotary rolling torque and contact area rate, thus determining the tonnage, power and deformation uniformity of the equipment. In order to save labor and reduce power, the swing angle γ The bigger the better: and γ The larger the, the more uneven the deformation of the workpiece, but most of the inclination angle of the swing head is γ ≤ 3 ° (especially for the equipment currently used for cold and warm rotary forging, the inclination angle of swing head is small, generally γ ≤ 2 °), so it has little effect on the non-uniformity of deformation. Therefore, considering comprehensively, within a certain range( γ ≤ 3 °) swing head inclination γ The bigger the better.