Abstract

Helical gear is widely used in high-speed and heavy-duty situations due to their smooth transmission and many other advantages. When a helical gear pair meshes, it is inevitably affected by friction, so it is necessary to take tooth surface friction into account when calculating the time-varying meshing stiffness (TVMS) of the helical gear pair. Firstly, the helical gear is cut into micro-element slices of spur gear by the slicing method, and then the meshing stiffness of micro-element slices is calculated by the energy method. Finally, the accurate TVMS of the helical gear pair is obtained by integral accumulation along the tooth width direction. The change rule of TVMS of the helical gear pair under zero friction, constant friction, and time-varying friction is studied. The action mechanism of tooth surface roughness, torque, speed, tooth width, and other parameters on TVMS of the helical gear pair under time-varying friction are revealed. The results show that the TVMS of the helical gear pair will change under the action of friction; under constant friction, the TVMS of the helical gear pair will decrease, and the greater the constant friction coefficient, the smaller TVMS; under the action of time-varying friction, the TVMS of the helical gear pair will decrease with the increase of tooth surface roughness, increase with the increase of input torque, speed, and tooth width, respectively.

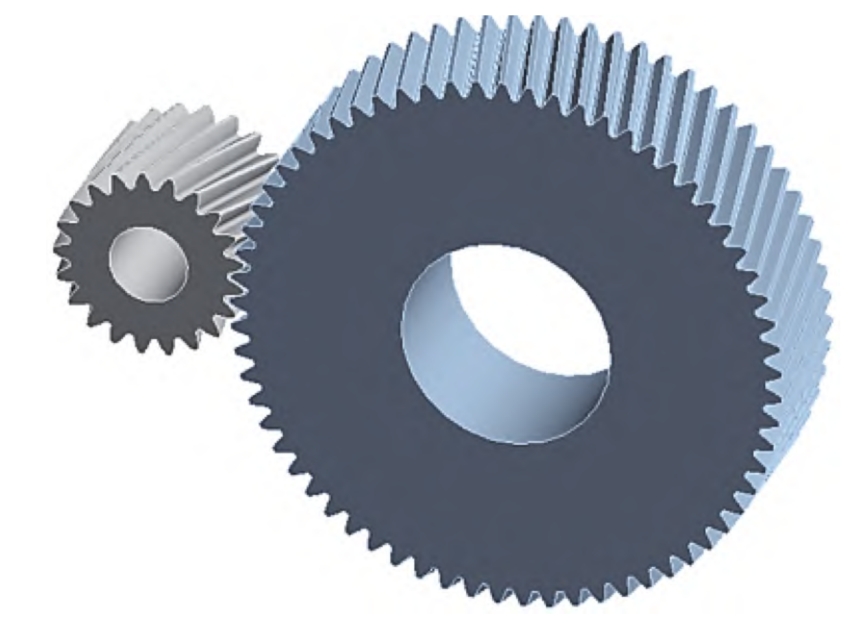

1. Introduction

The time-varying meshing stiffness (TVMS) of gear pairs is a critical factor affecting the dynamic performance of gear transmission systems. Accurate calculation of TVMS is essential for the design and optimization of gear systems. Helical gear, with their advantages such as smooth transmission and high load capacity, are widely used in various industrial applications. However, the TVMS of helical gear pairs is complex due to the involvement of multiple factors, including tooth surface friction, tooth surface roughness, torque, speed, and tooth width.

Previous studies have mainly focused on the TVMS of straight gears and helical gear without considering tooth surface friction. Some studies have explored the influence of tooth surface friction on the TVMS of straight gears but rarely on helical gear. Therefore, this paper aims to establish a TVMS model for helical gear pairs considering tooth surface friction, analyze the influence mechanism of different factors on TVMS, and provide a theoretical basis for the design and optimization of helical gear transmission systems.

2. Slicing Calculation Model for Helical Gear Pair Meshing Stiffness

2.1 Characteristics of Helical Gear Meshing

Unlike straight gears, the contact line length of helical gear gradually changes from zero to the maximum and then back to zero during meshing. This characteristic makes the algorithm for calculating the TVMS of helical gear different from that of straight gears. Therefore, it is necessary to first perform differential slicing and segmentation calculations when calculating the TVMS of helical gear and then calculate the overall TVMS based on the micro-element slice model.

2.2 Slicing Model of Helical Gear

The slicing method involves dividing the helical gear into multiple micro-element slices along the tooth width direction. Each micro-element slice can be approximately regarded as a straight gear for calculation.

2.3 Energy Method for Calculating Meshing Stiffness of Micro-Element Slices

The energy method is commonly used to calculate the meshing stiffness of gears. According to the energy method, the potential energy stored in the gear teeth during meshing can be divided into Hertz contact potential energy, bending potential energy, shear potential energy, and axial compression potential energy. The formula for calculating the meshing stiffness of micro-element slices is as follows:

kd=kf1+kb1+ks1+ka1+kf2+kb2+ks2+ka2+kh1

Where kf1, kb1, ks1, and ka1 represent the base, bending, shear, and axial compression stiffness of the driving gear, respectively; kf2, kb2, ks2, and ka2 represent the corresponding stiffness of the driven gear; and kh represents the Hertz contact stiffness.

The formulas for calculating bending, shear, and axial compression stiffness are as follows:

kb=i=1∑NΔy∫α1α2EA33(1+k1)2(α2−α)2dα

ks=i=1∑NΔy∫α1α2EA1.2(1+v)k2cos2α′dα

ka=i=1∑NΔy∫α1α22EAk2sin2α′dα

Where Δy is the width of each slice, N is the number of slices, E is the elastic modulus, A is a function related to the angle α, k1 and k2 are functions related to the angle α and the gear parameters, and v is the Poisson’s ratio.

The Hertz contact stiffness kh is calculated based on the Hertz contact law and is constant along the line of action, independent of the meshing process.

3. Modeling of Time-Varying Meshing Stiffness of Helical Gear Pair with Friction

3.1 Calculation of TVMS of Helical Gear Pair without Friction

When calculating the TVMS of a helical gear pair without considering friction, the energy method can be directly applied. The overall TVMS of the helical gear pair is obtained by integrating the meshing stiffness of each micro-element slice along the tooth width direction.

3.2 Calculation of Time-Varying Friction Coefficient

The time-varying friction coefficient μ between gear teeth can be calculated based on the thermal elastohydrodynamic lubrication (EHL) model proposed by Xu et al. The formula for calculating μ is as follows:

mu=ef(SRk,PhK,v0,Ra)∣SRk∣b3PhKb2Vekb6vb7Rkb8

f=b1+b4∣SRk∣PhKlgv0+b5eS+b9eRa

S=−∣SRk∣PhKlgv0

Where SRk is the slide-roll ratio, PhK is the gear contact stress, Ve and Vs are the entrainment and sliding speeds, respectively, RK is the combined curvature radius, v is the absolute viscosity, and bi (i=1-9) are regression coefficients.

3.3 Incorporation of Friction into TVMS Model

After obtaining the time-varying friction coefficient, it is necessary to incorporate the effect of friction into the TVMS model. The friction force Ff between gear teeth can be calculated as follows:

Ff=μF

Where F is the meshing force.

The friction force Ff can be decomposed into horizontal and vertical components Ff1 and Ff2, respectively:

Ff1=Ffcosαy

Ff2=Ffsinαy

These decomposed friction forces are then included in the formulas for calculating bending, shear, and axial compression stiffness, and the TVMS of the helical gear pair is recalculated using the energy method.

4. Influence Mechanism of Different Factors on TVMS

4.1 Influence of Constant Friction

Under the action of constant friction, the single-tooth stiffness of the helical gear changes during the meshing-in and meshing-out stages. At the pitch line, where the friction force is zero and its direction changes abruptly, the meshing stiffness of the helical gear pair also changes abruptly. the variation of TVMS of the helical gear pair under different constant friction coefficients.

Under the action of a constant friction coefficient, the TVMS of the helical gear pair decreases, and the greater the friction coefficient, the smaller the TVMS.

4.2 Influence of Time-Varying Friction

The time-varying friction coefficient varies with the meshing position, resulting in changes in the overall TVMS of the helical gear pair. the variation of TVMS of the helical gear pair under different time-varying friction coefficients.

Under the action of time-varying friction, the TVMS of the helical gear pair decreases with the increase of tooth surface roughness but increases with the increase of input torque, speed, and tooth width. Among them, the influence of tooth width is the most significant.

4.3 Influence of Tooth Surface Roughness

Tooth surface roughness affects the friction coefficient between gear teeth, thereby affecting the TVMS of the helical gear pair. the variation of TVMS of the helical gear pair with different tooth surface roughness values.

The TVMS of the helical gear pair decreases with the increase of tooth surface roughness.

4.4 Influence of Torque

The input torque affects the meshing force between gear teeth, thereby affecting the TVMS of the helical gear pair. The variation of TVMS of the helical gear pair with different input torques.

The TVMS of the helical gear pair increases with the increase of input torque.

4.5 Influence of Speed

The speed affects the sliding speed and contact stress between gear teeth, thereby affecting the friction coefficient and TVMS of the helical gear pair. the variation of TVMS of the helical gear pair with different speeds.

The TVMS of the helical gear pair increases with the increase of speed.

4.6 Influence of Tooth Width

The tooth width affects the number of micro-element slices and the overall stiffness of the helical gear pair, thereby affecting the TVMS. the variation of TVMS of the helical gear pair with different tooth widths.

The TVMS of the helical gear pair increases with the increase of tooth width.

5. Influence of Time-Varying Friction on Transmission Error

Transmission error is a parameter describing the unsmoothness of gear transmission, which measures whether the gear meshing deviates from the line of action. The formula for calculating transmission error is as follows:

LSTE=KF

Where F is the meshing force, and K is the TVMS.

Transmission error and TVMS are coupled and influence each other. Therefore, when TVMS changes with the time-varying friction coefficient, transmission error also changes accordingly. the variation of transmission error of the helical gear pair under different time-varying friction coefficients.

Transmission error increases with the increase of tooth surface roughness but decreases with the increase of input torque, speed, and tooth width. Among them, the influence of tooth width is the most significant.

6. Conclusion

In this paper, a TVMS model for helical gear pairs considering tooth surface friction is established based on the slicing method and energy method. The influence mechanisms of tooth surface roughness, torque, speed, and tooth width on TVMS under time-varying friction are analyzed. The main conclusions are as follows:

- Model Establishment: By simplifying the helical gear into a cantilever beam structure on the tooth root circle and considering tooth surface friction, a time-varying friction coefficient calculation model is established. This model is incorporated into the TVMS formula based on the slicing method and energy method, proposing an algorithm for calculating the TVMS of helical gear pairs considering time-varying friction.

- Influence of Different Factors on Friction Coefficient: The time-varying friction coefficient increases with the increase of tooth surface roughness, input torque, and tooth width but decreases with the increase of speed.

- Influence of Different Factors on TVMS: The TVMS decreases with the increase of tooth surface roughness but increases with the increase of input torque, speed, and tooth width. Among them, the influence of tooth width is the most significant.

The research results provide a theoretical basis for the design and optimization of helical gear transmission systems and have important practical significance for improving the dynamic performance and reducing vibration and noise of gear systems.