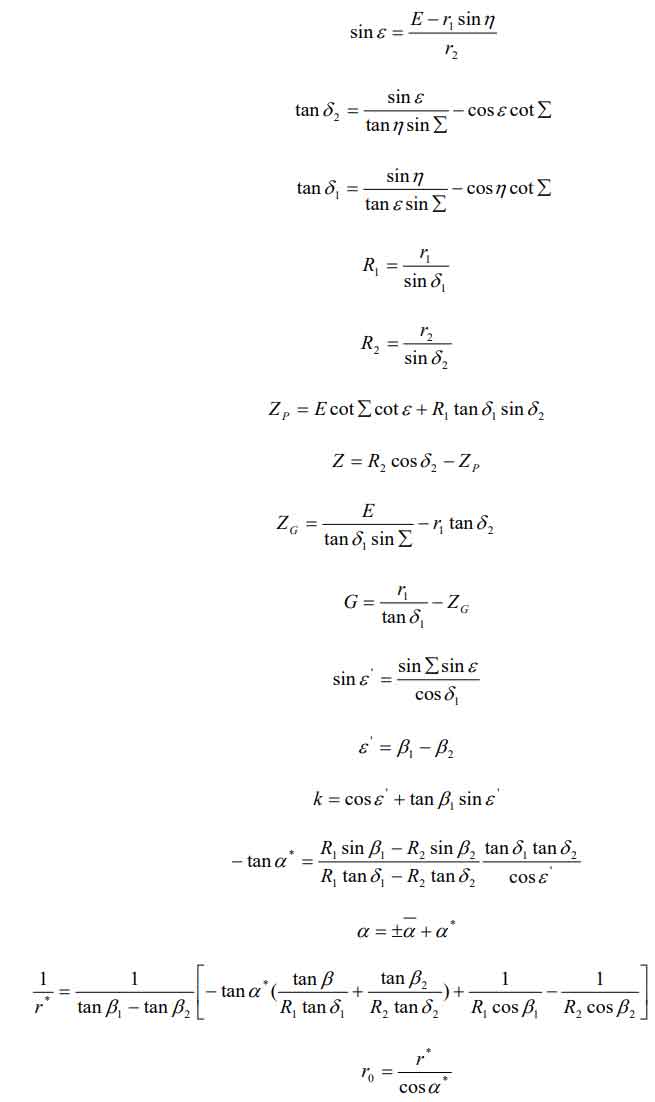

The calculation method of geometric parameters of hypoid gear formulated by Gleason company is to preliminarily preset the initial value of parameters on the basis of specific conditions, and use the initial value for two iterative calculations to obtain specific parameters. There are 16 independent equations in the mathematical model. The standard value of the hypoid gear with an axial intersection angle of Σ = 90 ° is in addition to the initially given offset distance E of the hypoid gear α , The other parameters include node position parameters, conjugate motion parameters, surface parameters at nodes and limit characteristic parameters. There are 20 parameters in total: offset angle of hypoid gear pair ε’ , Offset angle of large and small gears ε 、η , Bevel angle of large and small gear pitch δ 2 、 δ 1. Pitch radius R2 and R1 of large and small gears, pitch cone distance R1 and R2, relevant parameters Z, ZP, G and ZG determined by gear cone top, and helix angle of large and small gears β 2、 β 1. Gear pair pressure angle α , Ultimate pressure angle α* 、 Magnification factor K, cutter head radius r0, limit normal curvature radius R*. The specific 16 equations of the mathematical model of Gleason made hypoid gear are as follows:

According to the Gleason algorithm, the mathematical model of hypoid gear always has the above 16 independent equations, which are used to solve 20 parameters. Obviously, the values of parameters cannot be obtained. Therefore, the following restrictions are set in the design of the general Gleason geometric algorithm:

(1) Firstly, the meshing node of the gear pair should be located at the midpoint of the tooth width, and the diameter D2 of the large end pitch circle of the large gear that determines the bearing capacity of the whole gear pair and the tooth width b of the large gear that determines the bearing capacity of a single tooth are given;

(2) The value of helix angle of pinion node of gear pair is given;

(3) In order to select the radius of the machining cutter head, the curvature radius of the tooth surface along the tooth length direction is specified to be equal to the radius of the standard cutter head;

(4) Limit the transmission ratio of the gear pair in detail.

Gleason geometric parameter calculation method obtains the initial value of the design parameters from the given conditions combined with the design requirements, and carries out two iterative calculations with the mathematical model combined with the limiting conditions to obtain the specific geometric parameters.