Due to the mass and inertia of the gear, the meshing impact speed will produce meshing impact force. The size of the meshing impact force is related to the load, mass, speed and other factors transmitted by the gear. The mechanical model of the meshing impact force is shown in the figure.

The moment of inertia of the driving wheel and driven wheel is as follows:

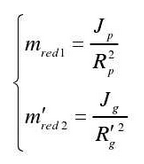

The moment of inertia of the driving wheel and the driven wheel is transformed into the equivalent mass on the instantaneous meshing line of the tooth pair

Where, is the instantaneous moment of inertia of the driving wheel; JG is the instantaneous moment of inertia of the driven wheel; BP is the width of the driving gear; BG is the width of the driving gear; ρ is the material density of the gear; HPR is; HPR is the radius of the inner hole of the driving wheel hub; rhG is the radius of the inner hole of the driven wheel hub; R’g is the instantaneous base circle radius of the driven wheel.

According to the meshing impact velocity and the equivalent mass of the meshing teeth, the impact kinetic energy of the meshing point can be obtained

According to the relationship among the kinetic energy EK, the maximum deformation δ s, the maximum impact force FS and the impact velocity vs in the impact dynamics theory, the following relationship can be obtained:

Among them, QS is the single tooth pair flexibility of the outside meshing point; JP and JG are the main moment of inertia of the driven wheel, RP is the base circle radius of the driving wheel; r’g is the instantaneous base circle radius of the driven wheel.

From the formula, the expression of the engagement impact force at the initial position of the engagement impact can be deduced as follows:

Because of the short time of meshing impact, the meshing impact force is usually simplified as sawtooth wave function. According to the percentage of meshing impact force in meshing period and the amplitude of meshing impact force obtained above, the meshing impact force curve as shown in the figure can be obtained.

The forming process of meshing impact and its influence on gear system are described. Firstly, the meshing impact time and the meshing impact velocity are deduced by using the geometric relationship of gear line engagement impact. Secondly, the meshing impact force amplitude is calculated by using the mathematical relationship among the parameters in impact mechanics. Finally, according to the meshing impact force amplitude and meshing impact time, the meshing impact force curve is simplified by sawtooth wave function.