The cutting process of gear hob should be divided into pre machining area and generating area; Most of the metal cut from the gear blank is carried out in the pre cutting area.

(1) The pre machining area is located on the side where the gear hob first cuts into the gear;

(2) The installation position of gear hobbing hob must contain the whole pre-processing area, otherwise the first cutter tooth at the cutting end will be overloaded, and the phenomenon of cutting may occur;

(3) The minimum length of the hobbing hob for machining a gear is equal to the length of the pre machining area, also known as the cutting edge length of the tool, which is equal to the length of the rough cutting area plus half of the length of the generating area.

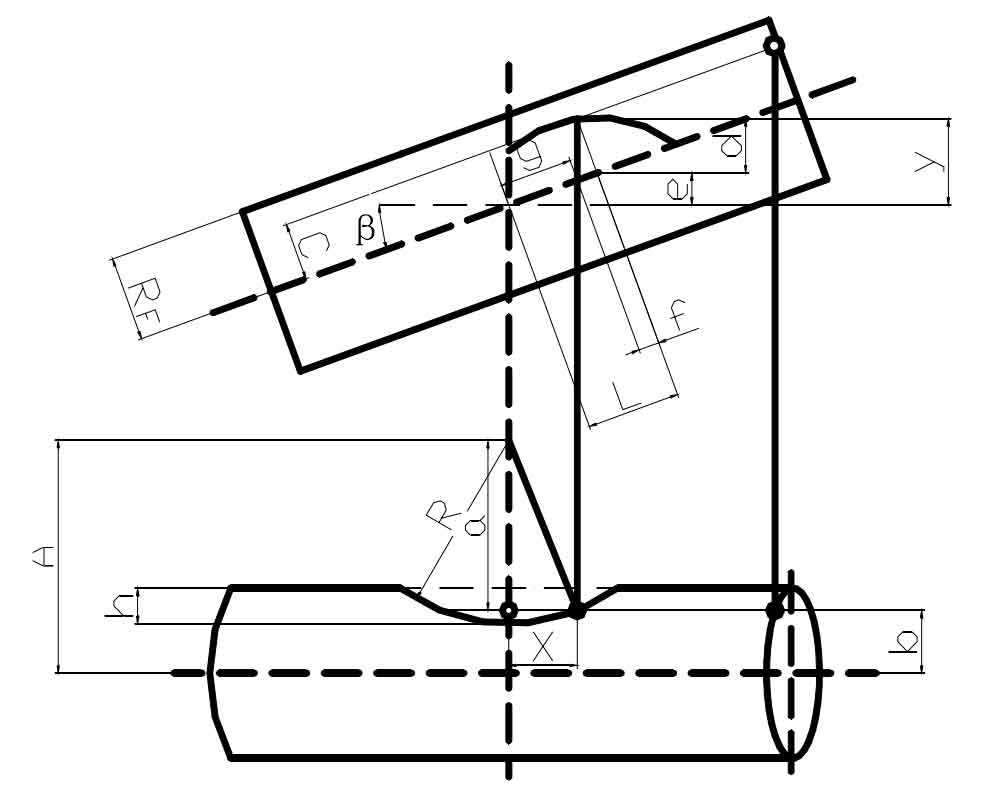

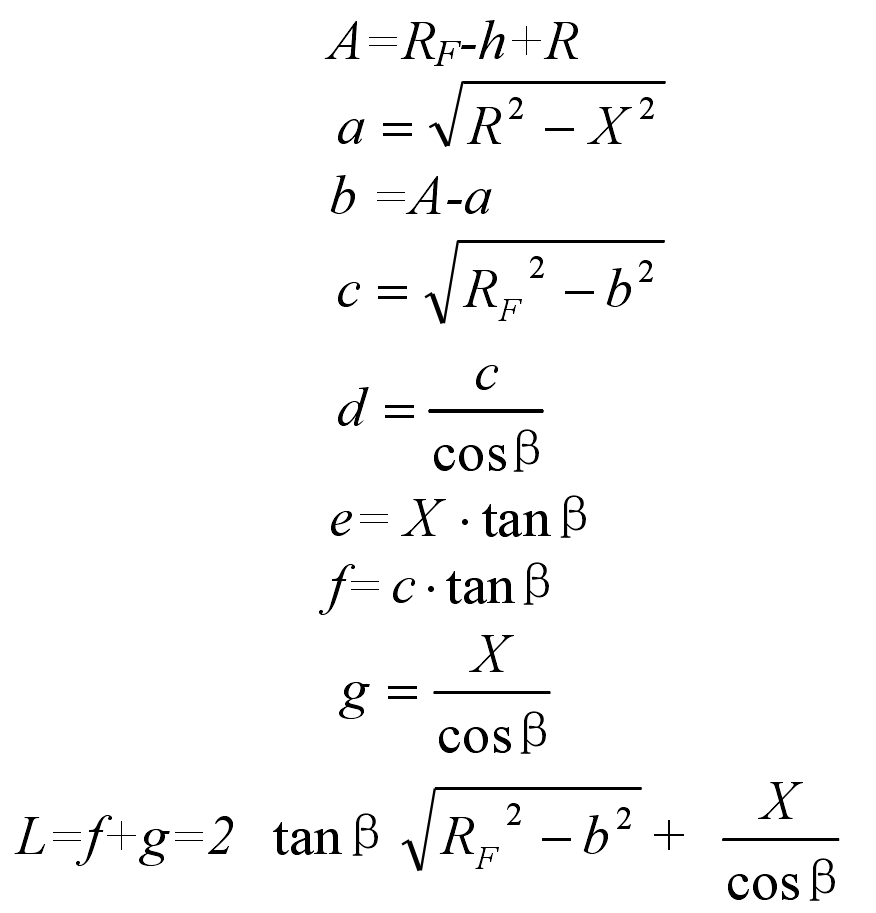

The calculation method of the shortest working length L of gear hobbing hob is shown in the figure, which can be seen from the geometric relationship in the figure:

Where:

RF – radius of gear hob;

H — cutting depth;

R – radius of gear top circle;

β—— Installation angle of gear hob;

L – the shortest length of gear hobbing hob.