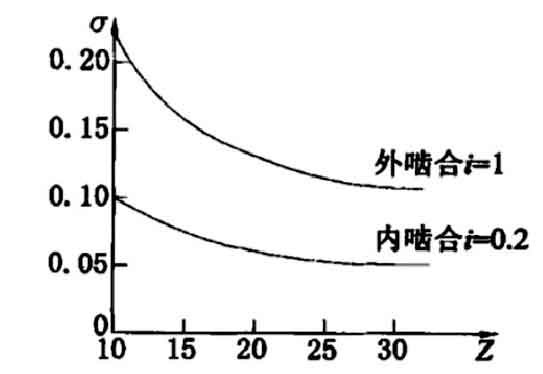

(1) Pump flow pulsation causes noise. In the process of operation, the pump is faced with the noise problem caused by flow pulsation phenomenon, and the possibility of flow pulsation being eliminated in the process of pump operation is very low. The results show that the flow pulsation of gear pump is affected by the number of gear teeth. The more the number of gear teeth, the more stable the system is and the less the noise the pump produces. Figure shows the relationship between the flow pulsation rate and the number of teeth of the gear pump. It can be seen from the figure that under the premise of the same number, the flow pulsation rate of the internal gear pump is smaller than that of the external gear pump. As for the internal gear pump, within a certain range, the more the number of gears, the smaller the flow pulsation rate of the pump. Therefore, to a certain extent, the noise problem caused by the flow pulsation is real, and it can not be completely eliminated. We can only take certain measures to reduce the flow pulsation, so as to reduce the system vibration and achieve the purpose of reducing noise.

(2) Noise caused by trapped oil. The vibration caused by trapped oil is also one of the main sources of noise. In the design of gear pump, it is required that the latter pair of gears must be meshed before the former pair of gears are out of meshing, that is, the overlap coefficient of gears of gear pump must be ≥ 1, so as to ensure the stable and reliable operation of gear pump. But at present, when the last two pairs of teeth enter the meshing state at the same time, a closed space will be formed between the two pairs of teeth. During the operation of the pump, the oil medium in the space will be affected by the force of the rotating gear, and this force changes obviously, which leads to the occurrence of “trapped oil phenomenon”. After the phenomenon of trapped oil occurs, the vibration of the unit increases, and the noise will be formed.

(3) Cavitation and cavitation produce noise. The phenomenon of trapped oil sometimes leads to the release of gas in the closed space and the formation of bubbles. Over time, it will produce the effect of “cavitation”, and then aggravate the vibration of the unit and cause noise. In addition, the air mixed in the hydraulic oil will separate air bubbles due to the low pressure effect after it enters the inner cavity. When these air bubbles enter the high pressure area with the gear rotation, the air bubbles will burst, which will produce a certain impact pressure in the gear pump, and then cause more noise in the gear pump.

(4) Gear meshing impact noise. In the process of pump operation, the meshing impact between gears will also produce noise, and the noise is related to the pitch error and tooth profile error between gears.

(5) Mechanical noise. In addition to the above reasons, mechanical factors are also one of the sources of noise, including unqualified bearings, unbalanced rotation of pump shaft, etc. most of the problems are caused by unqualified materials, imprecise manufacturing process, nonstandard installation, etc. Especially in the high-speed state, the imbalance problem of pump shaft rotation will be amplified, resulting in increased mechanical vibration and noise. In addition, long-term operation will cause wear of parts in the pump, which will lead to excessive clearance, increase pressure fluctuation and noise.