Introduction

In the wind energy industry, wind power gearboxes, as key transmission devices, play an important role in converting wind energy into electrical energy. However, the reliability and life of gearboxes are affected by various factors, one of which is the quality and temperature of the oil. The aging of the oil and excessive oil temperature may lead to performance degradation, increased failure, and even premature damage of the gearbox. In order to ensure the normal operation and extend the service life of wind power gearboxes, it is crucial to strengthen the quality of the oil and control the oil temperature. This article summarizes methods to strengthen the quality of the oil, avoid oil aging, and control the oil temperature, including proper oil selection, regular replacement, cooling system design, gearbox strengthening design, and cleaning and replacement of oil filters. By taking these measures, the reliability, performance, and service life of wind power gearboxes can be improved, ensuring the effectiveness and sustainable development of wind energy utilization.

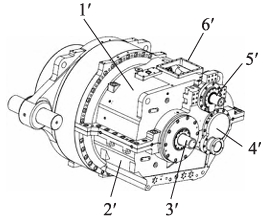

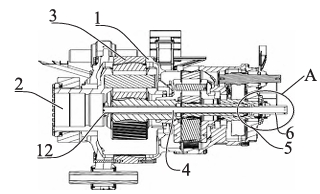

Working principle of cooling system of wind power gearbox

The working principle of the cooling system for wind turbine gearboxes is to maintain the temperature of the gearbox within an acceptable range by circulating cooling lubricating oil to ensure the normal operation of key components such as gears and bearings. The cooling system usually consists of a cooler, a cooling oil pump, oil pipelines, and control devices. When the wind turbine is running, a large amount of heat is generated inside the gearbox, which will cause the temperature of the lubricating oil to rise through heat conduction and fluid dynamics. After entering the gearbox, the lubricating oil absorbs heat through the lubrication and cooling effects of gears and bearings, and simultaneously carries away the friction heat of the lubricating components. Subsequently, the heat flows through the oil pipeline to the cooler. The cooler can be cooled by air or water. In an air cooling system, the heat on the surface of the cooler is transferred to the air through a fan, causing the temperature of the lubricating oil to drop rapidly. In a water cooling system, the lubricating oil passes through the cooler’s pipes and exchanges heat with cooling water, reducing the temperature of the lubricating oil. The cooling oil pump is responsible for transporting the cooled lubricating oil back into the gearbox to form a cycle. The control device can control the temperature and operating state of the gearbox to ensure the normal operation of the cooling system. Through the work of the gearbox cooling system, the temperature of the gearbox is effectively reduced, ensuring the reliability and longevity of the wind turbine. At the same time, it also improves the efficiency of wind energy utilization and power generation.

Reasons for high oil temperature in wind power gearbox

High shaft power and workload are one of the important reasons for the increase in oil temperature in wind turbine gearboxes. During the operation of wind turbines, due to the huge wind force, the wind wheel rotates at high speed, resulting in high shaft power. High shaft power represents the amount of electrical energy output by the wind turbine, which is related to the rotational speed and torque of the wind wheel. At the same time, for large wind turbines, due to their large size, their workload is also heavy. The increase in high shaft power and workload will lead to increased friction inside the gearbox, resulting in a large amount of heat. These heat cannot be dissipated well, leading to an increase in oil temperature.

Internal friction of gearbox

The internal friction of the gearbox is a major cause of the increase in oil temperature in wind turbine gearboxes. During the operation of the wind turbine, the gears and bearings Friction is inevitable in such components. Friction can cause energy loss and generate a large amount of heat. When gear teeth and bearings, as well as other

When the lubrication conditions between the contact surfaces are not ideal, the friction heat will further increase. This may be due to poor quality of lubricating oil, too little lubricating oil, or In addition, if the gearbox has gear wear, improper fit clearance, or incorrect alignment, it will increase the wear and tear of the gears and Friction of the bearing. The accumulation of these frictional heat over time will lead to an increase in oil temperature.

Insufficient cooling system