The pitch tooth line is a curve. This determines that when the teeth mesh, each pair of teeth can only be in local contact, and at least two pairs of teeth mesh at the same time at each instant. Therefore, compared with the spur bevel gear of the same size, it can not only transmit greater load. Moreover, the operation is more stable, and the noise and vibration are significantly reduced. The tooth profile is complex. When plastic forming the tooth profile, the movement route of metal filling the cavity is long, the flow resistance is large, and the tooth profile is difficult to fill.

Rotation direction:

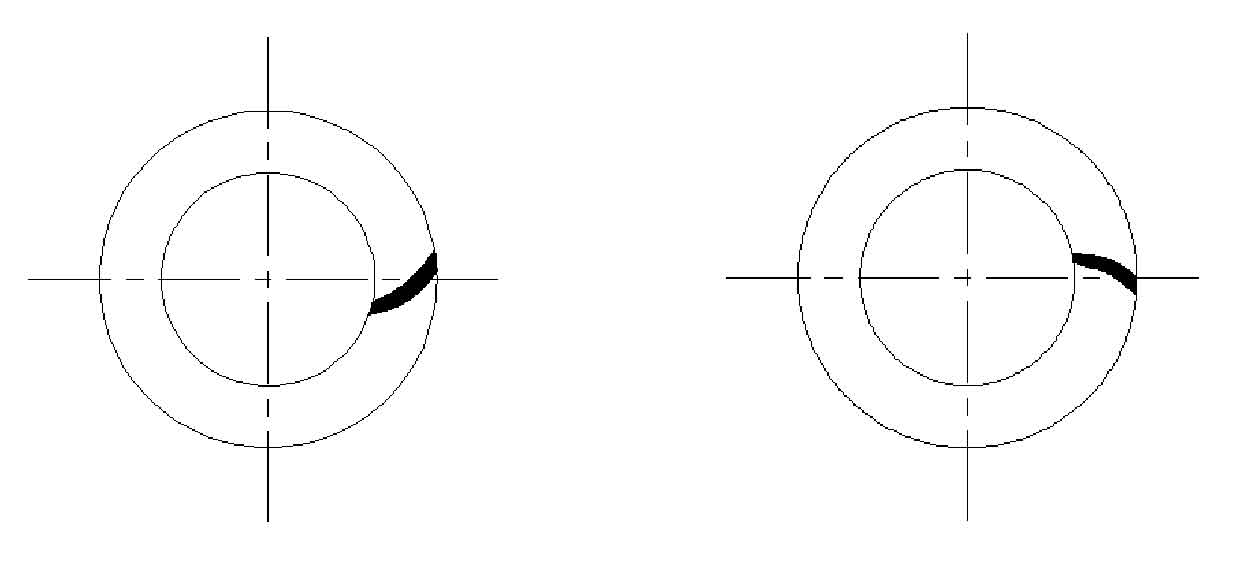

Spiral bevel gears can be divided into left-hand and right-hand gears according to the rotation direction, as shown in figures (a) and (b). The judgment basis is that the gear whose teeth incline to the bus in the counterclockwise direction is the left-hand gear, and the gear whose teeth incline to the bus in the clockwise direction is the right-hand gear. A pair of meshing spiral bevel gear pairs must have two gears with different rotation directions, otherwise, meshing cannot be realized.

Helix angle:

The pitch line is the intersection of the tooth surface and the pitch cone surface, and the included angle between the tangent of any point and the pitch cone bus becomes the spiral angle of that point. Use symbols β express. When the spiral bevel gear pair is meshed correctly, due to the relationship of spiral angle, the overlap coefficient increases, so the load specific pressure decreases and the wear is more uniform, which correspondingly increases the load capacity of the gear, so the service life of the gear is prolonged.