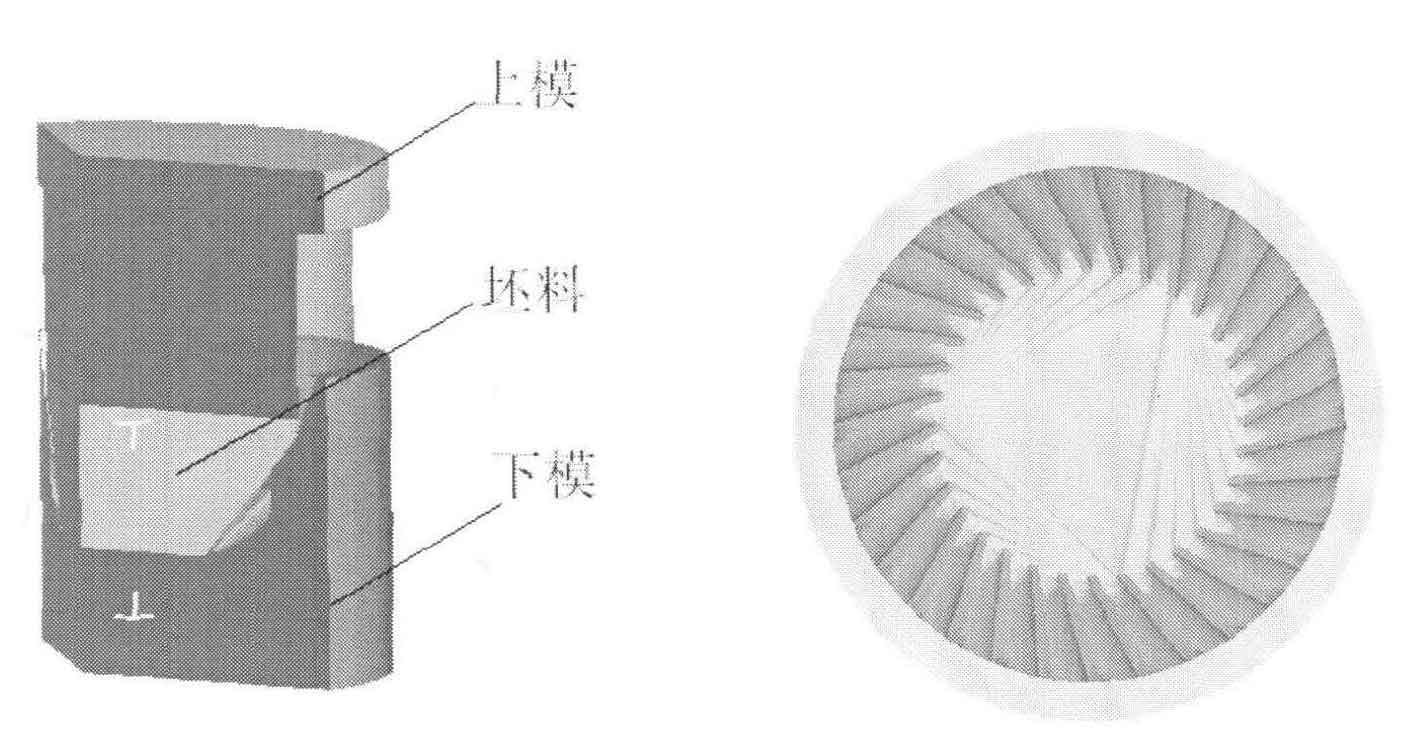

1.Establishment of finite element model

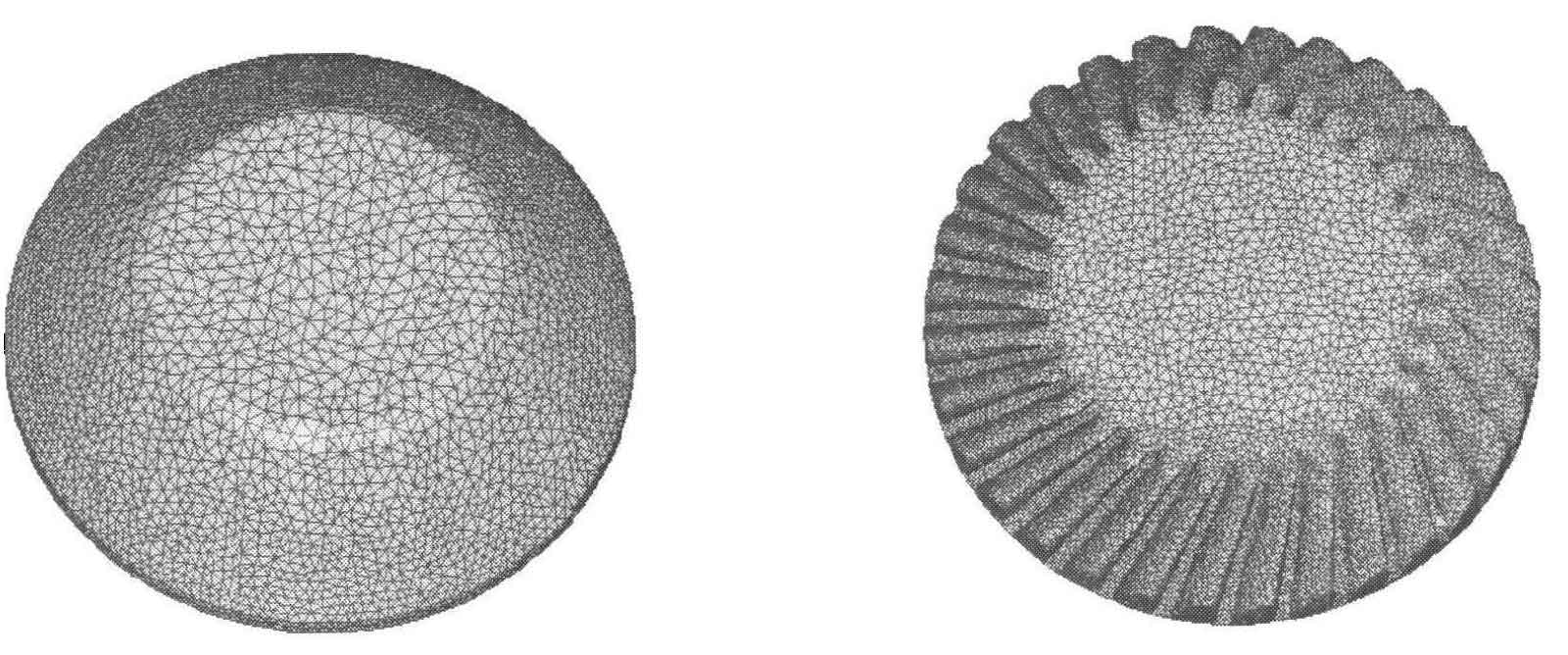

The finite element model is shown in Figure 1. The forging with gears is formed in the lower die. In order to ensure good forming and reduce the time of the initial free rough stage of forming, the outer diameter of the blank should be close to the tooth root circle, and the diameter of the blank should be close to the diameter of the tooth root circle. Therefore, the diameter of the large end face of the blank is 87mm, and the diameter of the small end face of the blank is 50.8mm. The total height of the blank is 23mm calculated under the condition of constant volume. The blank shape is similar to a cone, as shown in Figure 2.

2.Parameters and conditions for simulation

Aisi-4120 (20crmn steel) in Defrom-3D material library is selected as the blank material, and H-13 steel is selected as the die material. The blank temperature is 850 ° C, and the temperature effect in heat conduction and deformation between blank and die is ignored. The friction mode between blank and die is shear friction model, the friction factor is defined as 0.25, the downward speed of upper die is 5mm / s, and the finite element simulation process parameters of closed die forging of spiral bevel gear are shown in the table.

| Blank material | Die material | Blank temperature (° C) | Friction coefficient | Upper die speed (mm / s) |

| AISI-4120 | H13 | 850 | 0.25 | 5 |