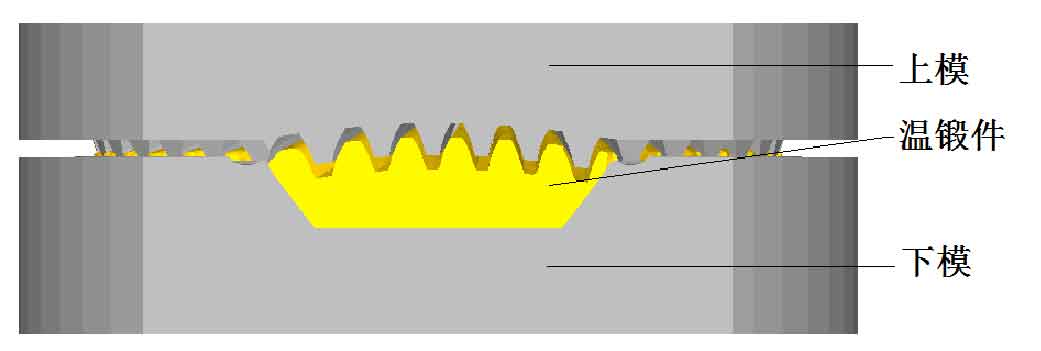

Use CATIA three-dimensional mathematical modeling software to establish the three-dimensional mathematical models of the upper die and lower die in the cold finishing process, and save them as STL format. Use DEFORM-3D software to output the three-dimensional mathematical model of spiral bevel gear forging obtained by warm precision forging and save it as STL format, and then import the assembly file in STL format into DEFORM-3D. The assembly drawing is shown in Figure 1.

Enter the DEFORM-3D pre-processing interface, and set the unit system to SI unit system (international standard unit system). Set the deformation temperature of the spiral bevel gear blank to 20 ℃, set the mesh division of the blank to 400000, and the temperature of the upper die and the lower die to 20 ℃, set the movement speed of the upper die to 12.5 mm / s downward along the z-axis, the material of the selected spiral bevel gear blank to 20mncr5, correspond to steel din-20mncr5 in the material library of DEFORM-3D, set the friction coefficient to 0.12 for cold forming, and generate the database file after checking, After exiting, click Run to enter the simulation stage for numerical simulation calculation.

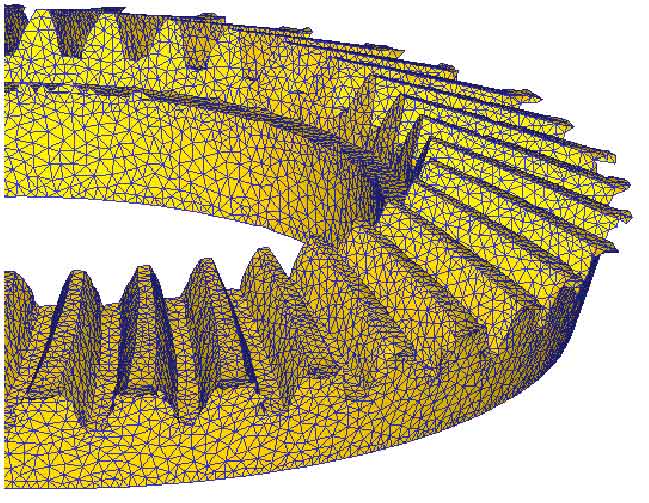

Figure 2 shows the grid distribution of the final step of cold finishing. It can be seen from the figure that the grid distribution of spiral bevel gear tooth profile is relatively dense and the grid is small, indicating that in the whole cold finishing process, the spiral bevel gear tooth profile is prone to grid distortion, so the grid is relatively dense when the grid is re divided, and the grids of other parts are stable, which proves that the deformation mainly occurs in the tooth profile during the cold finishing process. The main purpose of cold finishing is to finish the tooth profile and improve its dimensional accuracy.