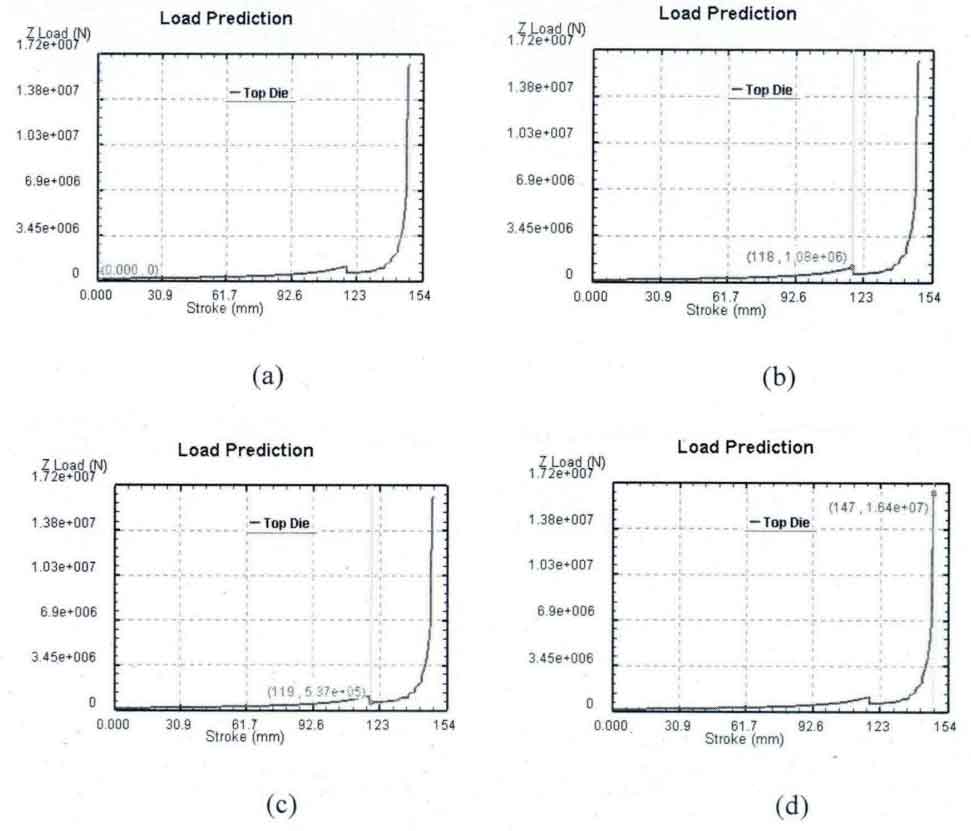

The forging object of spiral bevel gear blank (without punching and trimming) is shown in the figure. Comparing the numerical simulation results with the real forging, it is found that the shape and size of the spiral bevel gear forging obtained by numerical simulation are basically the same as the real forging.

It shows that the numerical simulation process is basically consistent with the actual spiral bevel gear forging process. The results of numerical simulation can provide a theoretical basis for the improvement of spiral bevel gear forging process.