1. Test purpose

Our company adopts high-grade and high-quality zocrmntih steel with 6 bandwidths according to the steel factory standard. According to the performance requirements of different parts, we select 20CrMnTiHA2, 20CrMnTiHA3 and 20CrMnTiHA4, which are respectively applied to the synchronizer part – two speed gear sleeve (representative of thin-walled parts), four speed gear (representative of transmission gear) and two shaft (representative of shaft parts) of hc7s-120 heavy truck gearbox, After heat treatment and carburizing treatment, 40 parts are put into operation for measurement and inspection, and the data are compared with the truck gear data made of ordinary 20CrMnTi steel processed under the same conditions to verify the influence of material hardenability on the deformation trend of truck gear.

2. Test materials

| Component | C | Mn | Si | P | S | Cr | Ti | Ni | Cu |

| 20CrMnTiHA2 | 0.18 | 0.98 | 0.24 | 0.01 | 0.023 | 1.10 | 0.062 | 0.054 | 0.10 |

| 20CrMnTiHA3 | 0.18 | 0.98 | 0.28 | 0.023 | 0.014 | 1.19 | 0.069 | 0.10 | 0.095 |

| 20CrMnTiHA4 | 0.18 | 1.09 | 0.29 | 0.015 | 0.017 | 1.18 | 0.062 | 0.061 | 0.076 |

The chemical composition and end quenching requirements of the test materials are shown in Tables 1 and 2.

| Project | J9 required scope | J15 required scope |

| 20CrMnTiHA2 | 30-36 | 24-31 |

| 20CrMnTiHA3 | 32-38 | 26-33 |

| 20CrMnTiHA4 | 35-41 | 28-35 |

3. Test parts

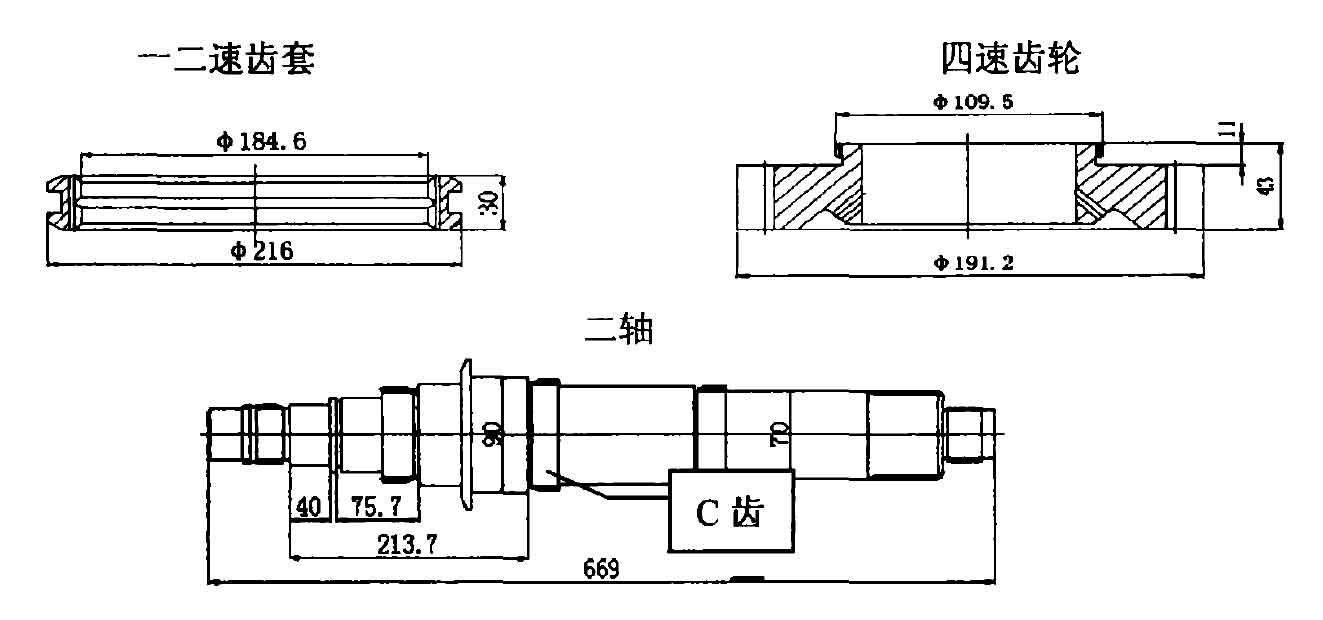

The shapes and dimensions of three typical parts used for the test are shown in Table 3 and figure.

| Name | Drawing No. | Material Science | Gear module | Number of teeth | Spline modulus | Number of teeth | Accuracy |

| First and second speed gear sleeve | 1701321 | 20CrMnTiHA2 | 2.5 | 48 | Grade 6 | ||

| Four speed gear | 1701351 | 20CrMnTiHA3 | 6 | 27 | 1.5 | 72 | Grade 6 |

| Two axis | 1701301 | 20CrMnTiHA4 | 2.5(C) | 34 | Grade 6 |