By using romax designer software, the optimal gear modification parameters are put into the gear modification module, and the simulation analysis is carried out under the same working conditions. Then the transmission error and unit length load of the gear before and after the modification are compared and analyzed.

Comparison of gear transmission error amplitude

The transmission error of the gear is studied in the software, and the transmission error amplitude before and after optimization is compared. As shown in Figure 1, the transmission error of the fourth gear after modification. It can be seen from the figure that the transmission error range of gear 4 after modification is 1.43 μ m, which is 37.83% lower than 2.30 μ m before modification, which indicates that modification can improve the meshing performance of gear.

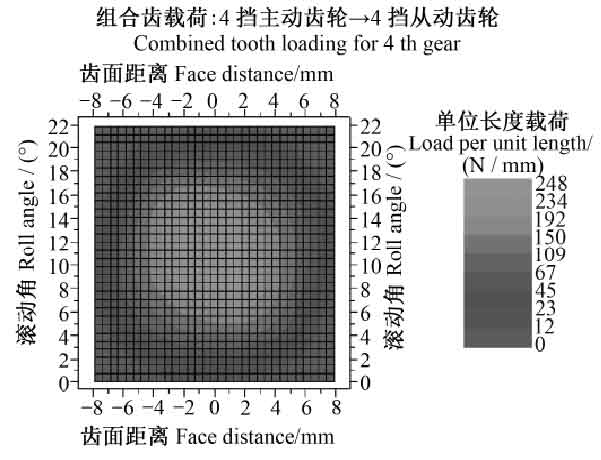

Gear unit length load comparison

As shown in Figure 2, the load distribution per unit meshing length of the modified fourth gear is shown. It can be seen from the figure that the maximum stress on the tooth surface of the gear decreased from 376 MPa before modification to 248 MPa after modification, a decrease of 34.04%. At the same time, the stress on the tooth surface of the gear is mainly concentrated in the center of the tooth surface, the stress distribution is more uniform, the edge effect is eliminated, and the bearing capacity of the gear is effectively improved.