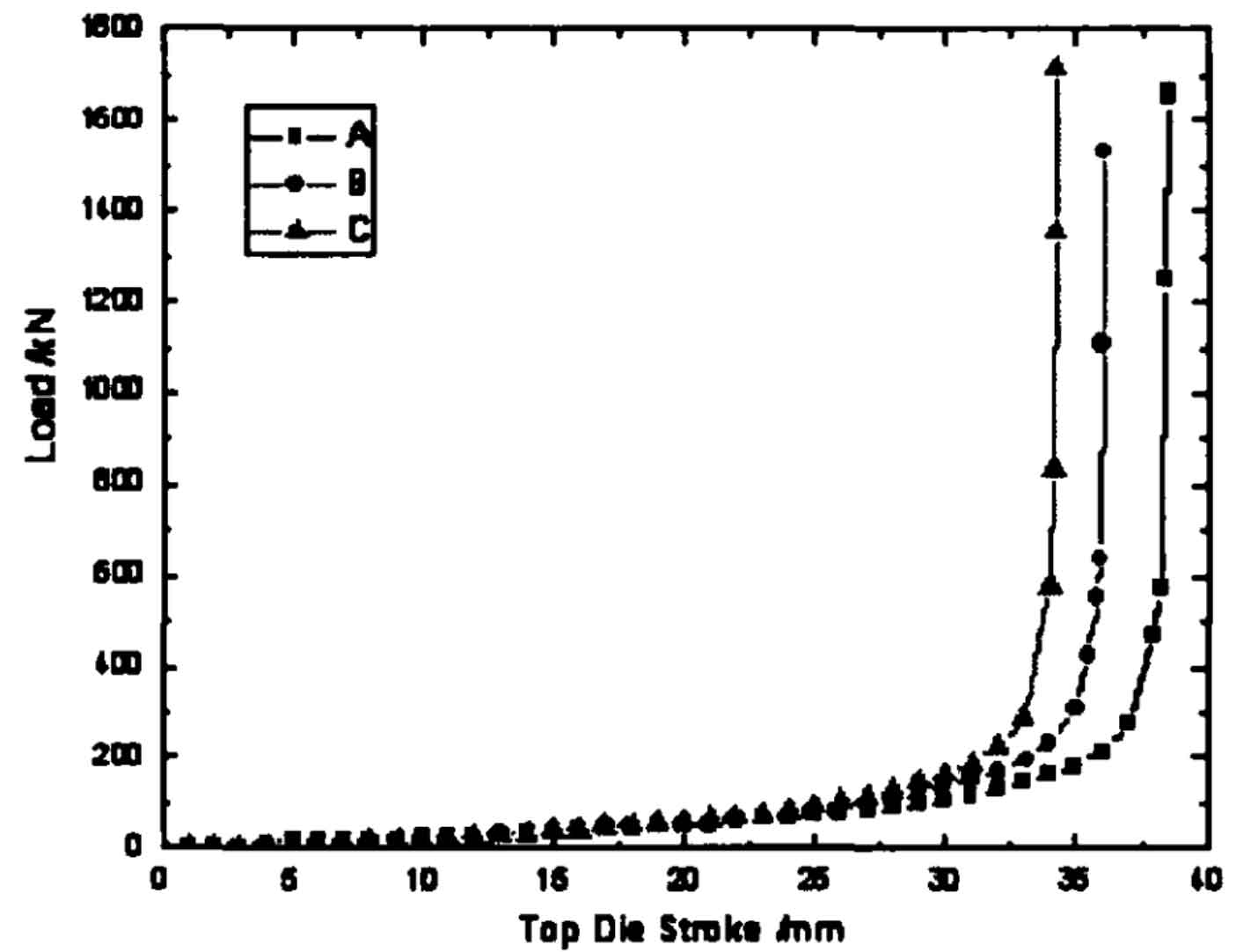

As shown in the figure, the load stroke curve of the three schemes shows that the load change laws of the three schemes are basically the same, which can be roughly divided into three stages. In the first stage, the metal flow is similar to free upsetting, and the load rises slowly; In the second stage, the metal began to fill the tooth cavity under the resistance of the back cone flash groove. With the continuous filling of the tooth cavity, the metal flow surface decreased rapidly, and the load rising speed began to accelerate; In the third stage, the tooth cavity is basically full, the metal mainly flows to the big end of the planetary gear to form a horizontal flash, and the load rises sharply.

Compare the three schemes: scheme a has a relatively long time in the first stage because its height diameter ratio is larger than the other two schemes at the early stage of forming, and its load is the lowest at the same stroke. However, with the increase of metal deformation in the later stage of forming, the final forming load is larger than that of scheme B, and the final forming load of scheme B is the smallest.

It can be seen from the figure that the final forming load of scheme B is 6000kn. Compared with the estimated forming force, it is found that the numerical simulation forming force is greater than the forming force obtained from the empirical formula. There may be two reasons: first, the speed of the actual friction press at the end of forging is close to zero, while the speed of the friction press at the end of numerical simulation is a constant value, resulting in a large strain rate at the end of planetary gear forging; Second, the thickness of flash is very small during the precision forging of planetary gears, the forming process is seriously distorted at the end of planetary gear forging, the mesh division is frequent, and the forming load rises rapidly in a small stroke.