The conical gear is a straight tooth with a modulus of 5 and a number of teeth of 20. The rotation of the handle on the tooling drives the tooling shaft system and the dynamic indexing plate to rotate. The indexing of the workpiece is realized by using the bolt, and the 20 tooth shapes of the conical gear are milled by the forming milling cutter.

1. Conical gear milling tooling structure

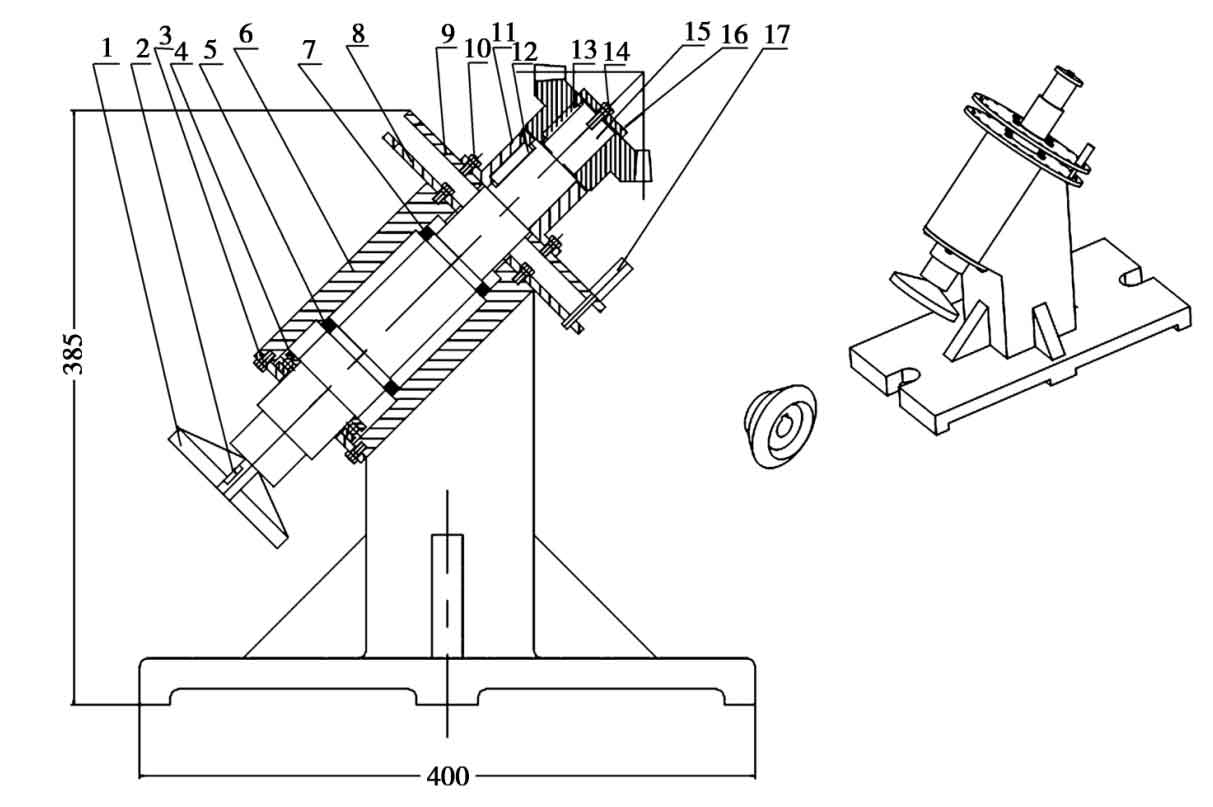

The structure of conical gear milling tooling is shown in the figure.

2. Working principle of conical gear milling tooling

Place the conical gear milling tooling on the worktable of x53 vertical milling machine, align the side of the bottom plate of the bearing seat with a meter, position the tooling in the T-groove of the worktable of the milling machine with a key, and press it with a pressing plate; With workpiece Φ Take the 30 hole as the benchmark, take the left end surface of the workpiece as the positioning surface, assemble the workpiece on the tooling, press it with the baffle, drive the rotation of the shaft system and the movable indexing plate through the rotation of the handle, insert the bolt to realize the indexing of the workpiece, and mill 20 tooth profiles of the bevel gear respectively.

By using the self-designed conical gear milling tooling, the conical gear teeth can meet the dimensional accuracy requirements required by the drawings, ensure the consistency of mass production, solve the problem of low processing efficiency, and improve the work efficiency and various performance indexes of products.