Gear hobbing processing and application practice show that the manufacturing errors of machine tools, cutting tools and gear blanks are reflected on the processed gears to varying degrees, resulting in gear motion error, stationarity error and tooth contact error.

In gear hobbing, the normal distance between the actual tooth profile contained in the working part of the tooth profile and the theoretical tooth profile forms the tooth profile error. When the two gears mesh with each other, the tooth shape error makes the contact deviate from the meshing line, and the instantaneous speed ratio changes suddenly, which destroys the stability of gear transmission and produces vibration and noise. Therefore, tooth profile error is one of the important factors affecting the stability of gear transmission.

In the process of gear hobbing, there are many reasons for the tooth profile error of hobbing gear. According to the formation principle of involute cylindrical gear, the basic circle of gear is the only parameter that determines the involute tooth profile. If the basic circle produces error (or instantaneous basic circle change) during gear processing, the tooth profile must have error. Therefore, the key to analyze the causes of tooth profile error is to find out the influence of various process factors on the radius of the base circle.

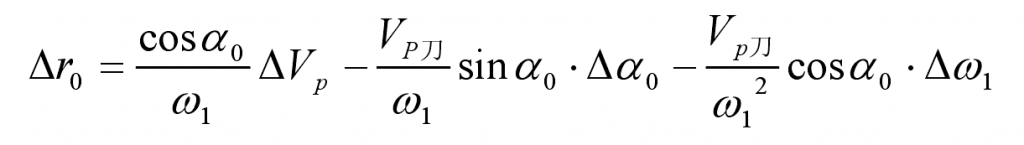

The radius error of base circle ∆ R0 is:

Where

α 0 – original tooth profile angle of gear hobbing hob;

VP cutter – Basic rack moving speed of gear hobbing cutter;

ω R — workpiece rotation speed.

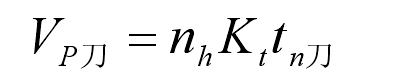

During gear hobbing, VP cutter is the basic rack moving speed of gear hobbing cutter, including:

Where:

NH — rotational speed of gear hob;

KT — number of heads of gear hobbing hob;

TN cutter – normal pitch of gear hob.

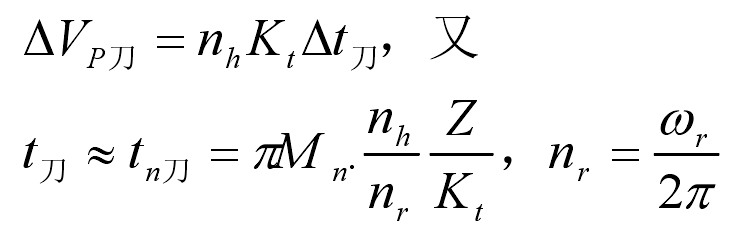

Generally, due to γ Very small, cos γ = 1, then:

Then:

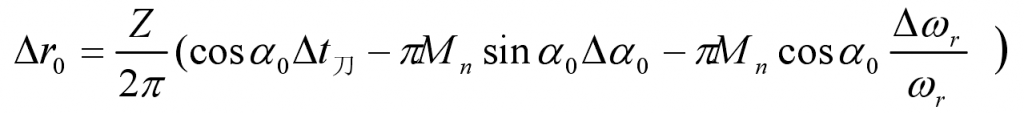

The above formula has more direct significance for the analysis of tooth profile error. The first two items in the brackets on the right are the tooth pitch error ∆ t of gear hobbing hob (or the axial position error of cutter teeth) and the tooth profile angle error ∆ α Base circle radius error caused by 0.