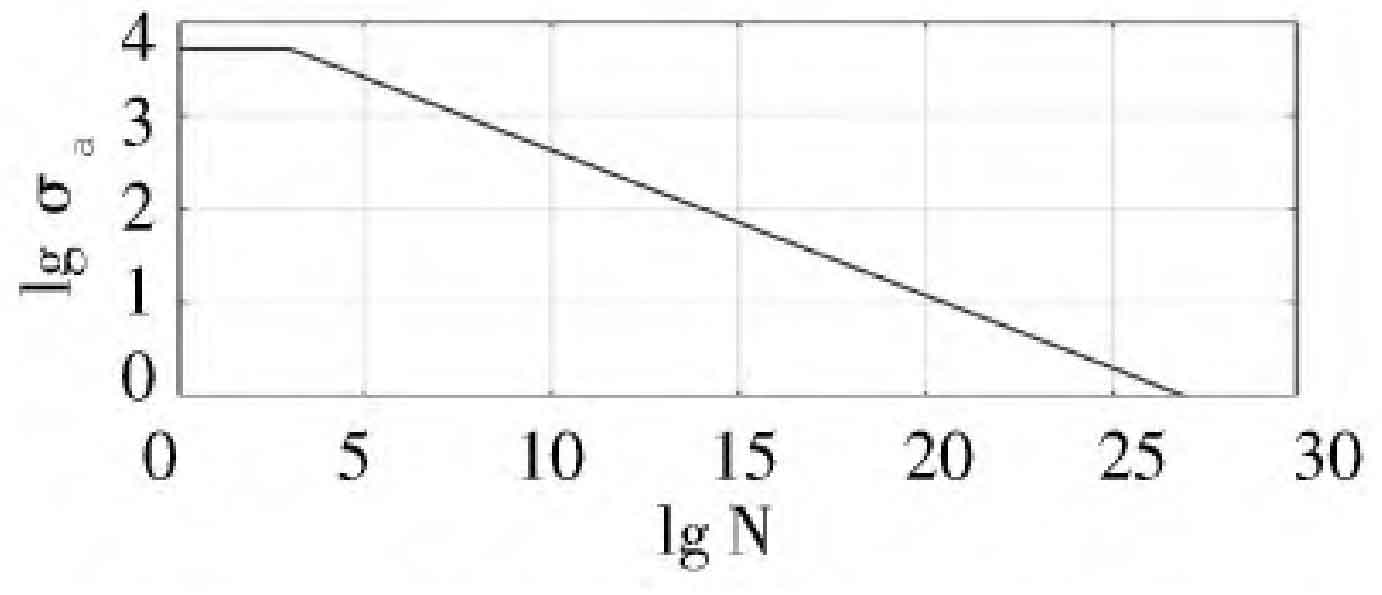

When the nominal stress method is used to calculate the contact fatigue of spur gear of reducer, it is mainly to determine the contact fatigue S-N curve of spur gear. The contact fatigue test of 20CrMnTi spur gear with carburized and quenched surface is carried out, and the gear material and heat treatment method in this document are the same as that of this reducer spur gear, and the gear size is also similar, so the results and contact stress fatigue limit value are directly used in this paper σ= 1576mpa, corresponding to the number of life cycles n = 5 × 107, but this value is obtained when the stress ratio r = – 1. According to the analysis, the contact stress of spur gear is r = 0, that is, the contact stress limit of spur gear should be σ a=788MPa。 According to the obtained test data of spur gears, it needs to be corrected before it can be used to study the fatigue life of spur gears in electric vehicle reducers. Because spur gears are subjected to random loads, the motor drive system will bear a large number of load frequencies lower than the fatigue limit, and these loads will also cause cumulative damage to spur gears. After considering these factors comprehensively, For the correction of S-N curve, the EM rule is selected, and the modified S-N logarithmic curve of spur gear with a survival rate of 99% is obtained, as shown in Figure 1.

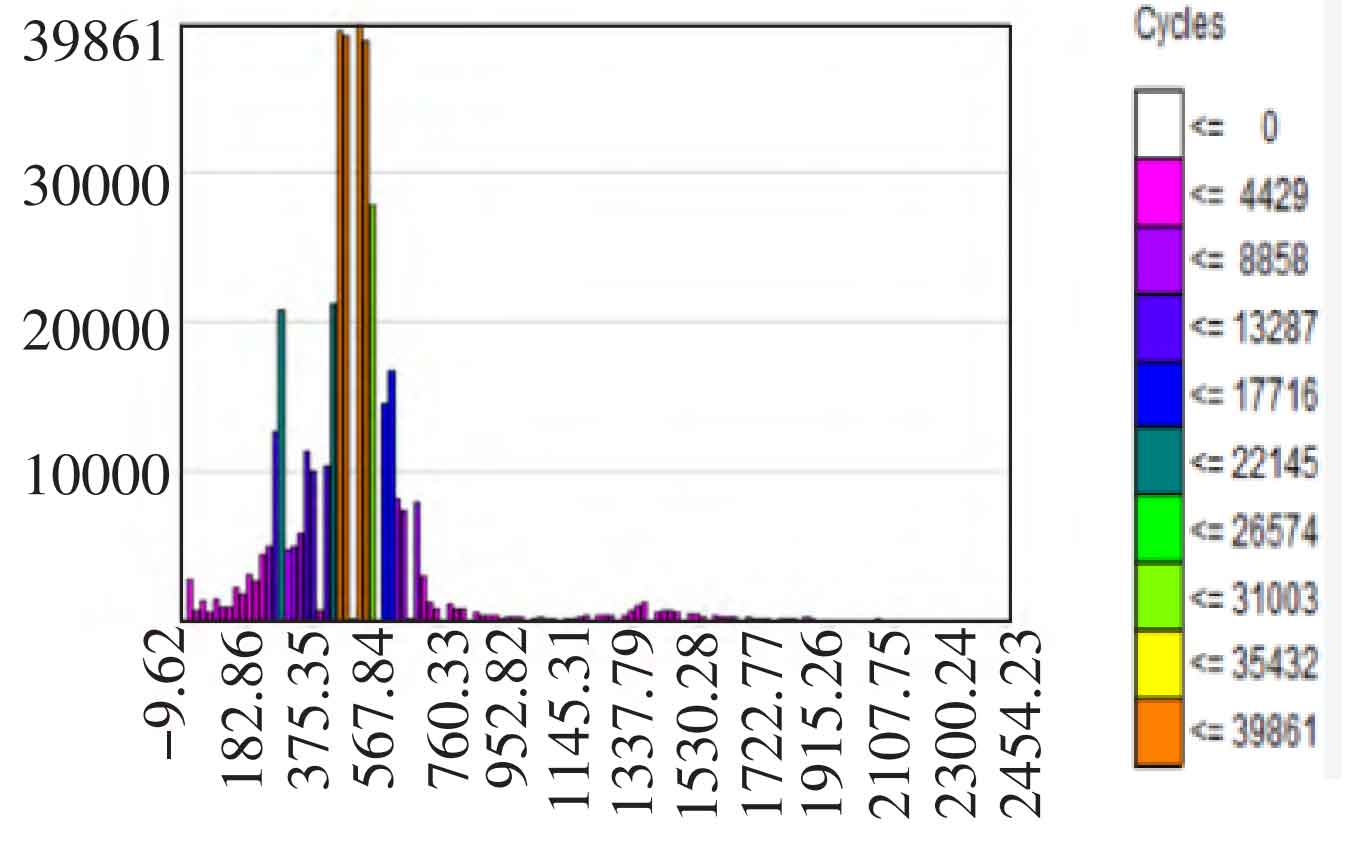

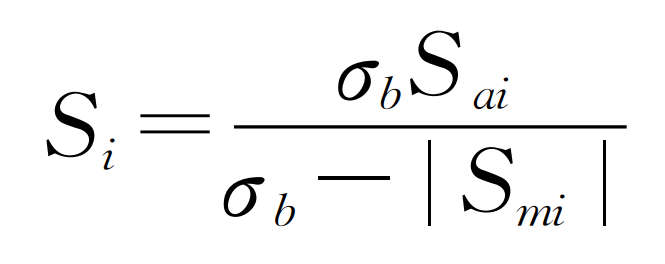

It can be seen from Figure 1 that the average stress is not all zero, so it needs to be converted into a stress cycle of zero average stress, which is converted by Goodman. The conversion formula is shown in Figure 2. The amplitude frequency relationship of contact stress of spur gear when the converted zero average stress is shown in Figure 2.

Where:

Si — equivalent zero mean stress;

Sai — the ith stress amplitude;

SMI — the ith stress mean value;

σ B — tensile strength limit of material

Sai and SMI can be calculated by Hooke’s law.