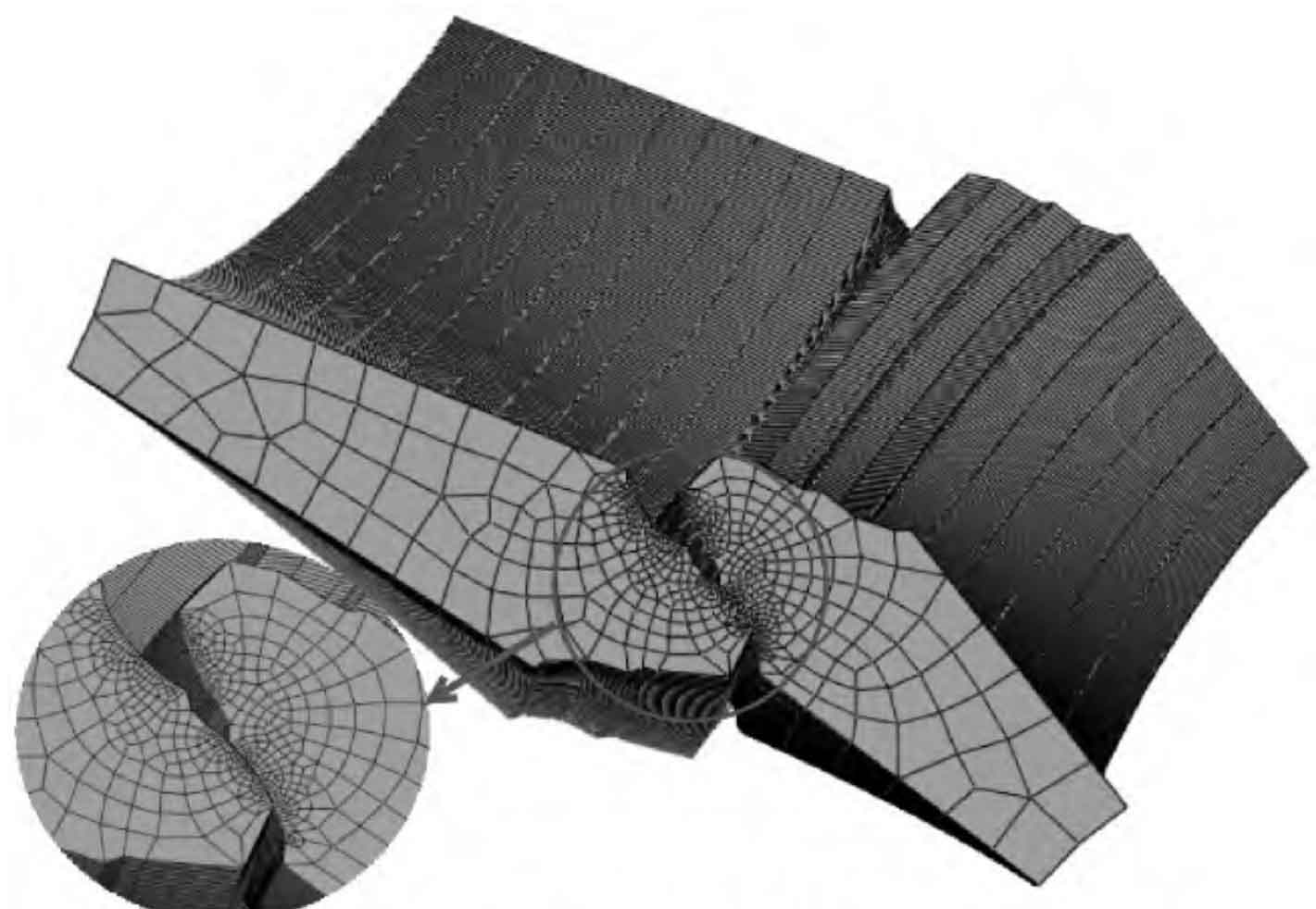

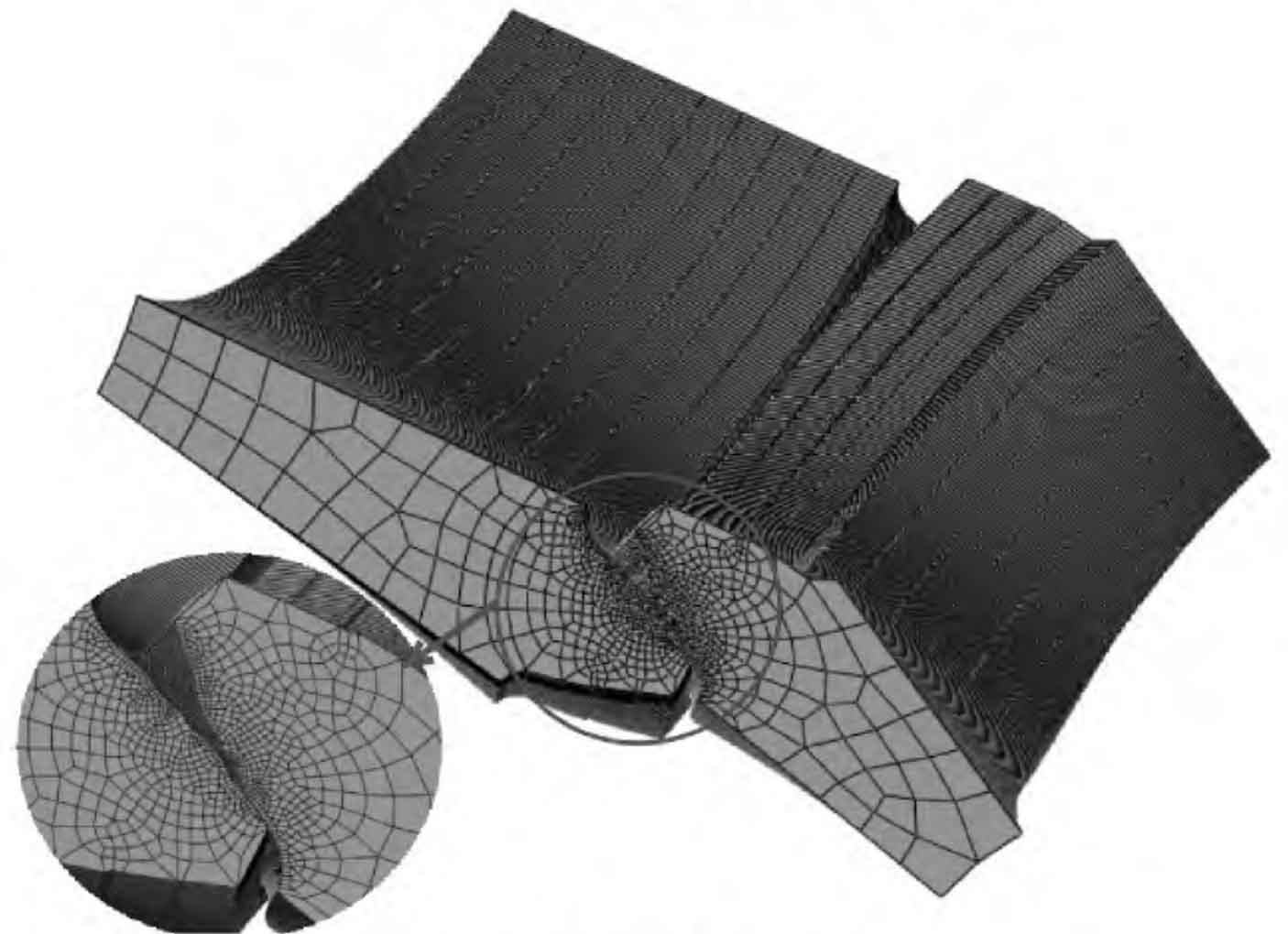

Select a single pair of teeth for tooth surface contact stress analysis, import the three-dimensional solid models of double circular arc profile gear and four circular arc profile gear established in Pro /engineer software into ABAQUS software, and set the material elastic modulus E = 2 06 × 105Mpa, Poisson’s ratio μ = 0. 3。 Select tetrahedral mesh to mesh the gear. In order to improve the calculation speed and ensure the accuracy of tooth surface contact stress, refine the mesh on the mutual contact surface of two pairs of tooth surfaces, and select a coarser mesh on the non-contact surface, as shown in Figure 1. The inner ring of the gear teeth of the big gear is fully constrained, and the inner ring of the pinion leaves only rotational degrees of freedom and constrains other degrees of freedom. Define the contact surface and apply torque to the inner ring of the pinion. In this paper, the torque is 1000 Mn. The stress nephogram is obtained through calculation, as shown in Figure 2.

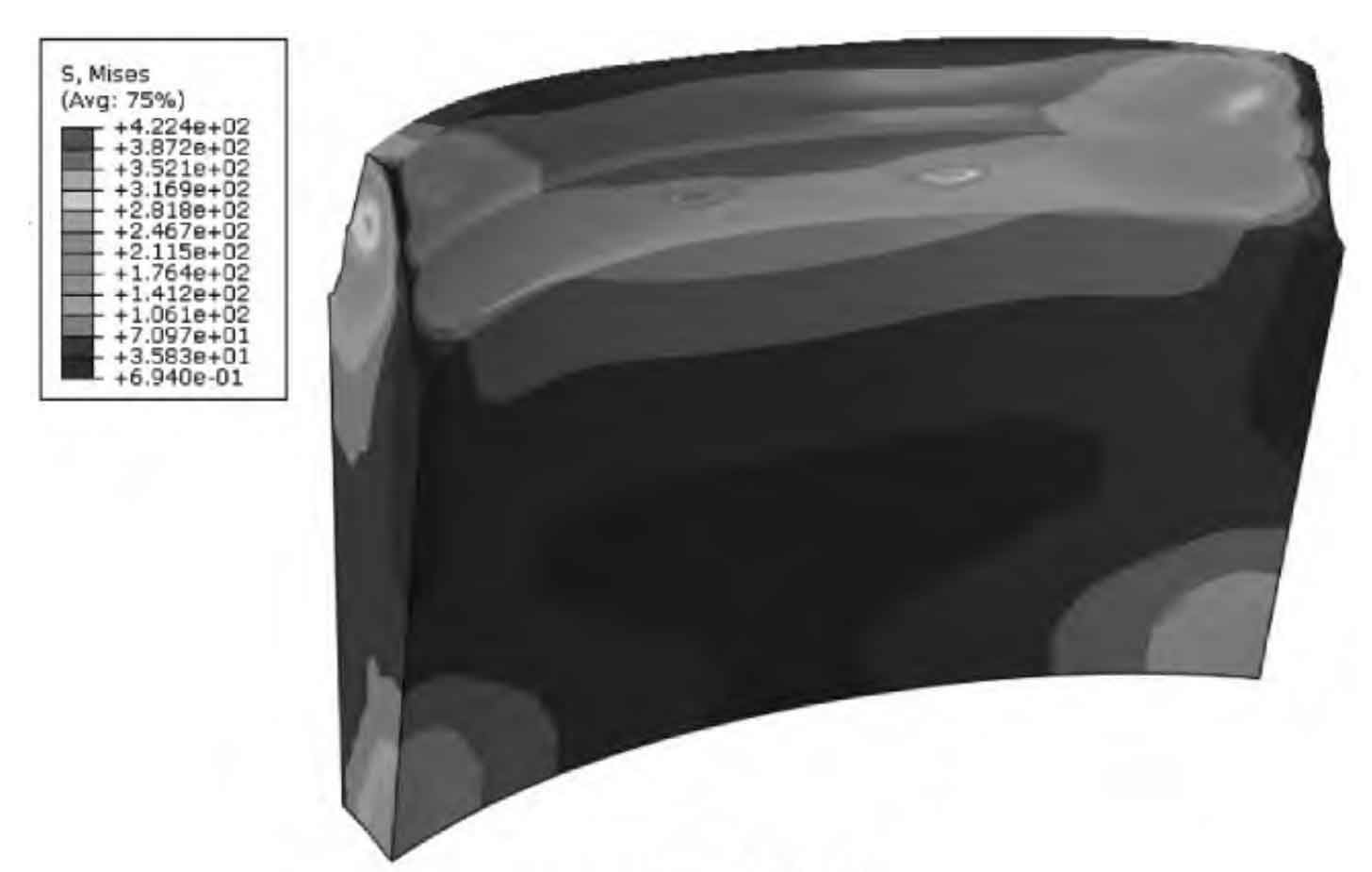

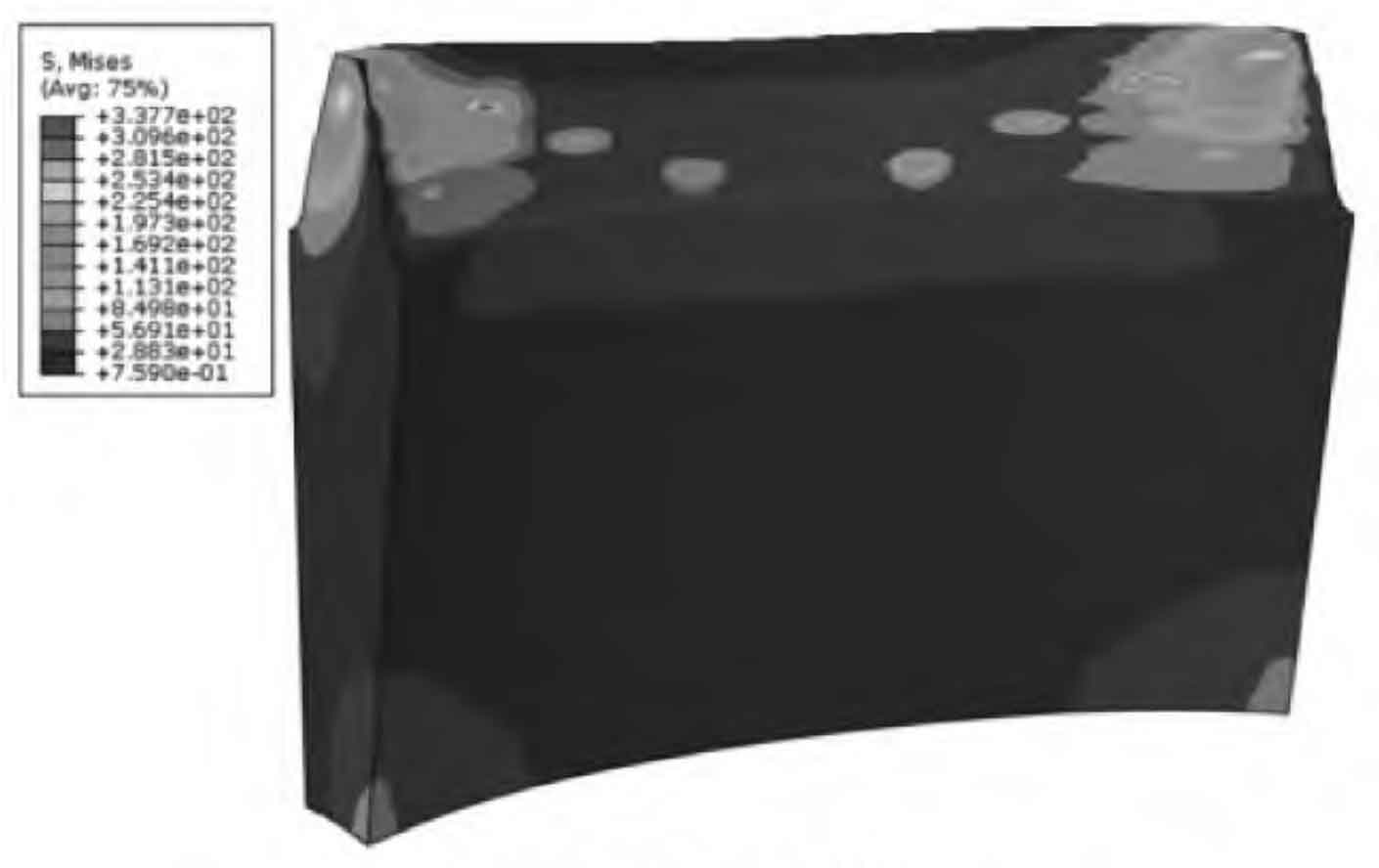

Since the selected gear meshing position can make all meshing points enter the meshing, it can be seen from Figure 2 that the double circular arc gear tooth surface consists of four contact points, while the four circular arc gear tooth surface has eight contact points, which is consistent with the theory. The maximum contact stress on the tooth surface of double circular arc gear is 422 MPa, while the contact stress on the tooth surface of four circular arc gear is 337 MPa, and the contact stress on the tooth surface of four circular arc gear is about 80% of that of double circular arc gear. The finite element analysis results show that increasing the number of tooth contact points can significantly reduce the tooth contact stress of the gear.