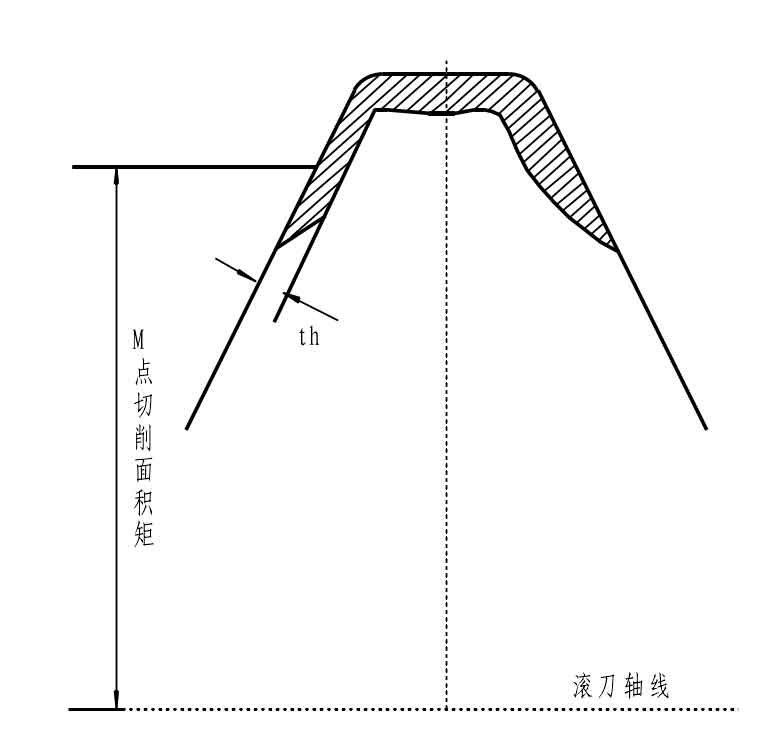

The cutting pattern of gear hobbing hob teeth reflects the metal process and tooth profile formation in the cutting groove of gear hobbing hob, the load distribution and change of each tooth of gear hobbing hob, the cutting shape and change, etc. The point matrix of the rake face of the gear hobbing hob continuously truncates the spiral fibers in the tooth groove area to be processed. The intersection points of each spiral fiber and the rake face of the gear hobbing hob at a certain moment form the cutting pattern of the cutter teeth at the moment, as shown in Figure 1.

At any point in the cutting pattern of the rake face of the gear hobbing hob, the cutting area moment TA of a cutter tooth is shown in Figure 1. Point m represents the area of 2100 µ m on the rake face, and the area moment is the product of the area and the distance from point m to the axis of gear hobbing hob. Since the area represented by each point is the same, the area moment is expressed by the distance from the point to the axis of gear hobbing hob.

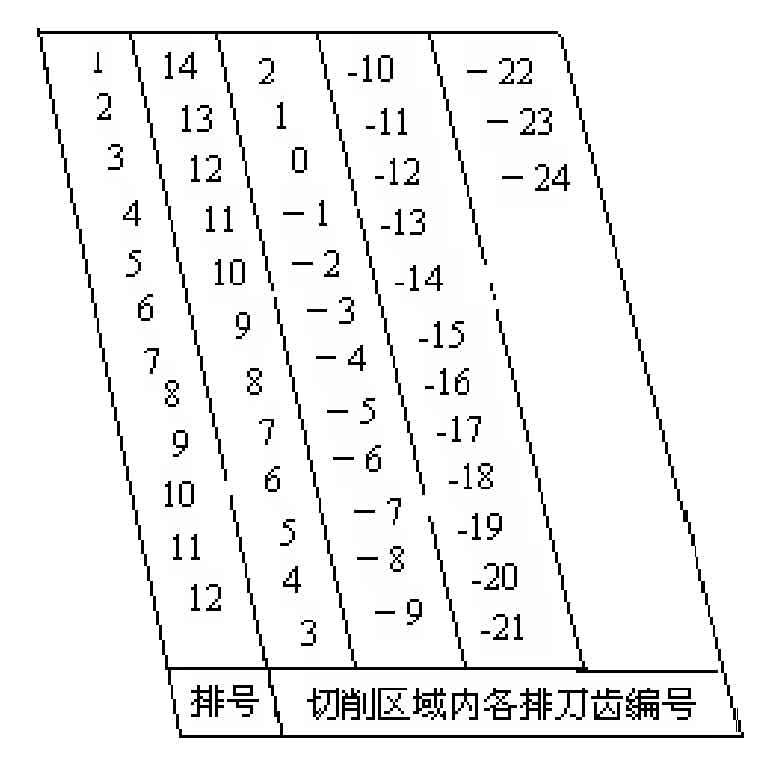

There are mm points in the cutting pattern of the rake face of the gear hobbing hob, and the distance from the point n to the axis of the gear hobbing hob is NL. At any time, the cutting area moment of this tooth on the gear hobbing hob is the sum of the distances from each point in the cutting area to the axis of the gear hobbing hob. In the actual machining process, the gear hobbing hob and the blank go deep into each other. The cutter teeth participating in cutting on the gear hobbing hob do not participate in cutting in turn, but one or several rows participate in cutting at the same time. Use a gear hobbing hob with 12 chip holding slots to process the gear. The arrangement of the cutting teeth of the gear hobbing hob is shown in Fig. 2. The first cutting tooth is No. 14, and the end tooth is No. 24. In the cutting length area along the axial direction of the gear hobbing hob, when all the cutter teeth enter the cutting state, for the first row of cutter teeth, No. 14 cutter teeth are cutting at the same time, and No. 2, No. 10 and No. 22 cutter teeth are also cutting at the same time, but the processed tooth grooves are not the same tooth groove, but four adjacent tooth grooves. At this time, the gear hobbing hob rotates one circle, The gear turns a tooth (in the mathematical model, all movements are completed by the gear hobbing hob, that is, the gear hobbing hob turns a tooth in the opposite direction relative to the gear).

Starting from the No. 2 cutter tooth, the cutting pattern of No. 2 cutter tooth at different cutting angles can be obtained by cutting the tooth groove studied. These cutting patterns are used to replace the actual cutting patterns in the actual machining process. When the No. 14 cutter is cutting, the No. 2 cutter is also cutting at the same cutting angle. Obviously, there is a time difference between the two cutting patterns, that is, the cutting pattern of No. 2 cutter obtained from the mathematical model is the cutting pattern after the gear hobbing hob rotates for one circle and feeds a small distance along the gear axis, but considering the actual machining process of the cutter, The linear speed of the main cutting motion and gear rotation motion of the gear hobbing hob is much larger than the axial feed speed of the gear hobbing hob.

In theoretical research, the axial feed of gear hobbing hob can be ignored, so that the two cutting patterns can replace each other, and the error after replacement is allowed. By analogy, the cutting pattern of a row of cutter teeth participating in the cutting process at the same time can be obtained according to the cutting pattern of each cutter tooth in the cutting process of a tooth slot. The cutting area of the same row of cutter teeth participating in cutting is the sum of the cutting area of each cutter tooth, and the cutting area moment is the sum of the cutting area moment of each cutter tooth. Therefore, it is easy to calculate the cutting area and cutting area moment of gear hobbing hob with 12 rows of cutter teeth at different cutting angles.