1. Introduction

Die casting machines play a crucial role in modern industrial production, and the control box is the key interface for operators to interact with the machine. The height adjustment of the control box is essential for operator comfort and work efficiency. This article focuses on the design and analysis of a rack and pinion lifting mechanism for die casting machine control boxes, aiming to provide a practical and efficient solution.

1.1 Background

The traditional control box structures of die casting machines have limitations. The fixed height structure lacks flexibility, while the intelligent electric lifting system has high costs and complex maintenance. Therefore, there is a need for a new design that can balance cost and functionality.

1.2 Objectives

The main objective of this study is to develop a lifting mechanism that is easy to operate, stable, and cost-effective. By using a rack and pinion system, the control box can be adjusted to different heights to meet the needs of various operators.

2. Existing Technologies

2.1 Fixed Height Structure

- Description: As shown in Figure 1, it is supported by welded steel pipes or profiles.

- Advantages: Simple and economical.

- Disadvantages: Lack of flexibility, unable to adjust height according to operator needs, which may cause discomfort or strain.

2.2 Intelligent Electric Lifting System

- Description: As shown in Figure 2, the height is adjusted by a servo motor driving a ball screw.

- Advantages: High convenience.

- Disadvantages: High cost, complex maintenance, and high technical requirements for maintenance personnel.

| Comparison Items | Fixed Height Structure | Intelligent Electric Lifting System |

|---|---|---|

| Cost | Low | High |

| Flexibility | Low | High |

| Maintenance Complexity | Low | High |

3. New Scheme Design

3.1 Overall Structure

The new lifting mechanism mainly consists of a rotating part, a lifting part, and a locking part. The control box is installed on the lifting part, and the height can be adjusted by operating the rotating part.

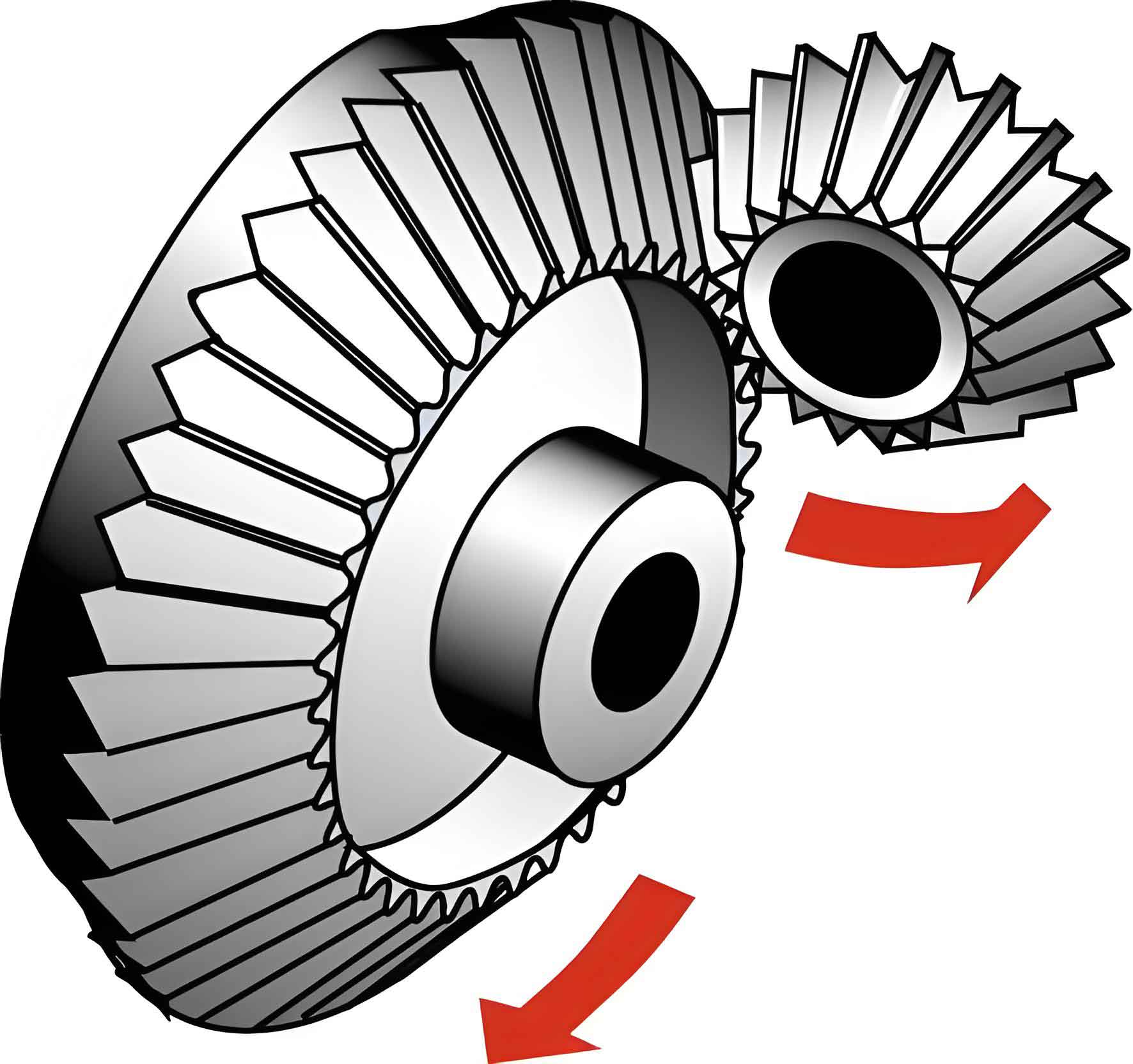

3.2 Rotating Part

- Components: Comprises a bearing seat, bearings, a crank handle, keys, a shaft, and an outer guide square tube.

- Function: The crank handle is connected to the shaft via a key. When rotated, it transmits torque to the shaft, driving the gear on the outer guide square tube to rotate. The bearings and bearing seats provide stable support, reducing friction and noise.

3.3 Lifting Part

- Components: Includes an inner square tube, rack fixing blocks, and a rack.

- Function: The rack is fastened to the inner square tube through the fixing blocks and meshes with the gear. When the gear rotates, the rack moves vertically, adjusting the height of the control box. The use of 45# steel after heat treatment ensures mechanical properties such as wear resistance.

3.4 Locking Part

- Components: Consists of an anti-rotation component, a handle screw, and an open-ended spacer.

- Function: After reaching the desired height, the handle screw is rotated to lock all moving parts, preventing slippage or displacement. This simple and effective locking mechanism ensures the stability and safety of the device.

4. New Scheme Verification

4.1 Three-Dimensional Modeling

Using SolidWorks software, a detailed three-dimensional model of the lifting mechanism was created. The dimensions, tolerances, and assembly relationships of each component were accurately defined. The height adjustment range of the mechanism was set to 0 – 300 mm to accommodate different operator heights.

4.2 Finite Element Analysis

- Static Analysis: Using the Simulation plugin, static mechanical analysis was performed under a maximum load of 200 N. Stress and strain analysis of key components such as the shaft and gear (as shown in Figures 7 and 8) indicated that all components maintained good structural stability with no significant deformation or failure risk.

- Future Tests: To further evaluate the long-term performance of the design, fatigue testing and dynamic response simulation are planned. These tests will help optimize parameter settings and ensure the final product meets or exceeds expected performance standards.

5. Advantages of the New Scheme

5.1 Stable Structure and High Reliability

- Precise Gear and Rack Engagement: Ensures accurate and consistent height adjustment during lifting. The heat treatment process of the gear and rack enhances their wear resistance and long-term stability.

- Smooth Rotation Support: The use of bearings and bearing seats provides stable rotation, reducing friction and mechanical noise, thereby extending the service life of the equipment.

- Effective Locking Mechanism: The simple yet reliable locking structure ensures the control box remains firmly in place after height adjustment, preventing any unwanted movement and ensuring operator safety.

5.2 Comfortable Operation

- Ergonomic Design: The optimized position of the crank handle on the right side and upper part of the control box allows operators to adjust the height comfortably, reducing fatigue.

- Flexible Height Adjustment: The design of the inner square tube enables a wide range of height adjustments, catering to operators of different heights and enhancing operational flexibility and convenience.

5.3 Cost Advantage

- Low Manufacturing Cost: Compared to the complex intelligent electric lifting system, the simple mechanical design of the rack and pinion lifting mechanism significantly reduces production and manufacturing costs, making it suitable for mass production.

- Reduced Maintenance Cost: The elimination of unnecessary complex structures and the ease of disassembling and replacing key components simplify the maintenance process. Operators and maintenance personnel can quickly detect and repair common faults, ensuring high equipment availability and low downtime. Additionally, the reduced number of components leads to lower costs and time for maintenance and replacement, improving the overall economic efficiency of the equipment.

6. Conclusion and Future Work

6.1 Conclusion

The proposed rack and pinion lifting mechanism for die casting machine control boxes offers a practical and efficient solution. Through optimized mechanical design, it achieves a balance between convenience, stability, and cost. The verification through three-dimensional modeling and finite element analysis demonstrates its technical feasibility and excellent performance.

6.2 Future Work

- Process and Material Optimization: Future efforts will focus on further optimizing the manufacturing process and material selection of the gear and rack to enhance their performance and durability.

- Hybrid Design Exploration: Research will be directed towards exploring a hybrid design that combines automated control with manual adjustment to meet a broader range of industrial requirements.

In summary, this new design has the potential to significantly improve the operation comfort and efficiency of die casting machines, providing a valuable solution for the industry.

7. Detailed Design Considerations

7.1 Gear and Rack Design

The gear and rack are crucial components in the lifting mechanism. Their design parameters directly affect the performance of the entire system. The gear is designed with a specific module and number of teeth to ensure smooth meshing with the rack. The rack, on the other hand, is designed with appropriate tooth profile and length to achieve the desired height adjustment range.

- Tooth Profile: The involute tooth profile is chosen for its smooth meshing characteristics and ability to transmit power efficiently. This profile minimizes wear and tear during operation, ensuring a long service life for the gear and rack.

- Module Selection: The module is determined based on the load requirements and the desired precision of height adjustment. A larger module provides higher strength but may result in a coarser adjustment. After careful consideration, a suitable module is selected to balance strength and precision.

- Material Selection: High-quality alloy steel is used for the gear and rack. This material offers excellent mechanical properties such as high strength, hardness, and wear resistance. Heat treatment processes are applied to further enhance these properties, ensuring reliable operation under heavy loads.

7.2 Bearing and Shaft Design

The bearing and shaft assembly provides the necessary support and rotational motion for the lifting mechanism. The design focuses on minimizing friction, ensuring smooth operation, and maximizing the load-carrying capacity.

- Bearing Type Selection: Deep groove ball bearings are chosen for their ability to handle both radial and axial loads. They offer low friction and high rotational speed capabilities, making them suitable for this application. The size and number of bearings are determined based on the load calculations and the required service life.

- Shaft Design: The shaft is designed with appropriate diameter and length to transmit torque from the crank handle to the gear. It is made of high-strength steel and undergoes surface treatment to improve its wear resistance. Keyways are machined on the shaft to ensure a secure connection with the crank handle and the gear.

7.3 Structural Design of the Lifting Frame

The lifting frame provides the overall support and guidance for the height adjustment. It is designed to be rigid and stable to ensure accurate and safe operation.

- Material Selection: The frame is constructed using high-strength aluminum alloy or steel. These materials offer a good combination of strength and light weight. The choice of material depends on factors such as cost, weight requirements, and environmental conditions.

- Cross-Sectional Shape: The cross-sectional shape of the frame members is optimized to provide maximum rigidity with minimum material usage. Rectangular or square cross-sections are commonly used, and reinforcements are added at critical points to enhance the overall strength.

- Connection Design: The frame members are connected using bolts, rivets, or welding, depending on the design requirements. Welding is often preferred for its high strength and rigidity, but proper welding techniques and quality control are essential to ensure the integrity of the joints.

8. Assembly and Installation

8.1 Assembly Process

The assembly of the lifting mechanism is a critical step to ensure its proper functioning. The following is a general overview of the assembly process:

- Component Preparation: All components are inspected and cleaned before assembly. Any burrs or surface imperfections are removed to ensure smooth mating surfaces.

- Gear and Rack Installation: The rack is first installed on the inner square tube and fastened securely using the rack fixing blocks. The gear is then mounted on the shaft and aligned with the rack to ensure proper meshing.

- Bearing and Shaft Assembly: The bearings are pressed onto the shaft and installed in the bearing seats. The shaft is then inserted into the outer guide square tube, and the necessary spacers and retaining rings are installed to ensure proper axial positioning.

- Crank Handle Installation: The crank handle is attached to the shaft using a key and secured with a set screw. The handle is positioned at the ergonomic location for easy operation.

- Locking Mechanism Installation: The anti-rotation component, handle screw, and open-ended spacer are installed in the appropriate positions. The locking mechanism is adjusted to ensure proper locking and unlocking functions.

8.2 Installation Requirements

Proper installation of the lifting mechanism on the die casting machine is essential for its safe and efficient operation. The following installation requirements should be followed:

- Alignment: The lifting mechanism must be installed in a vertical position and aligned with the control box. Any misalignment can cause binding or uneven loading, leading to premature wear and reduced performance.

- Mounting Surface Preparation: The mounting surface on the die casting machine should be clean, flat, and free from any debris or contaminants. Adequate mounting bolts or brackets are used to secure the lifting mechanism firmly in place.

- Clearance and Space Requirements: Sufficient clearance should be provided around the lifting mechanism to allow for smooth operation and maintenance. Any obstructions in the movement path can cause damage to the mechanism or interfere with its proper functioning.

- Testing and Adjustment: After installation, the lifting mechanism should be tested for proper operation. The height adjustment range, locking mechanism, and smoothness of movement are checked and adjusted if necessary.

9. Maintenance and Troubleshooting

9.1 Regular Maintenance

To ensure the long-term reliability and performance of the lifting mechanism, regular maintenance is required. The following maintenance tasks should be performed:

- Lubrication: The gear, rack, bearings, and other moving parts should be regularly lubricated with a suitable lubricant. This helps reduce friction, wear, and noise. The lubrication intervals depend on the operating conditions and the type of lubricant used.

- Inspection: Regular visual inspections are carried out to check for any signs of wear, damage, or looseness. The gear teeth, rack, bearings, shafts, and locking mechanism are examined for cracks, chips, or excessive wear. Any abnormalities are addressed promptly.

- Cleaning: The lifting mechanism and its surroundings should be kept clean to prevent the accumulation of dust, debris, or other contaminants. Cleaning helps maintain the proper functioning of the components and reduces the risk of corrosion.

9.2 Troubleshooting Common Issues

Despite proper maintenance, some issues may still arise. The following are some common problems and their possible solutions:

- Difficulty in Lifting or Lowering: This could be due to insufficient lubrication, misaligned gear and rack, or damaged teeth. Check the lubrication level and condition, realign the gear and rack if necessary, and inspect for any damaged teeth. Replace any worn or damaged components.

- Excessive Noise or Vibration: This may indicate worn bearings, loose components, or improper meshing of the gear and rack. Inspect the bearings for wear and replace if needed. Tighten any loose bolts or fittings. Check the gear and rack alignment and adjust if necessary.

- Locking Mechanism Failure: If the locking mechanism fails to hold the position, check the handle screw for tightness and the condition of the open-ended spacer. Replace any damaged or worn parts. Ensure that the anti-rotation component is functioning properly.

10. Safety Considerations

10.1 Operator Safety

The safety of the operator is of utmost importance. The following safety features and precautions are incorporated in the design:

- Guards and Protective Covers: Appropriate guards and protective covers are installed to prevent the operator from coming into contact with moving parts. These covers are designed to be easily removable for maintenance purposes.

- Emergency Stop Button: An emergency stop button is provided within easy reach of the operator. In case of any emergency, the operator can quickly stop the operation of the lifting mechanism.

- Training and Instructions: Operators are provided with proper training on the operation and maintenance of the lifting mechanism. Clear instructions and safety guidelines are posted in the work area to ensure safe operation.

10.2 Equipment Safety

In addition to operator safety, the safety of the equipment itself is also crucial. The following measures are taken to protect the equipment:

- Overload Protection: The design incorporates overload protection mechanisms to prevent damage to the lifting mechanism in case of excessive loads. This could be in the form of a shear pin or a torque limiter.

- Failure Detection and Alarm: Sensors are installed to detect any abnormal conditions such as excessive temperature, vibration, or misalignment. An alarm system is activated in case of any detected faults to alert the operator and maintenance personnel.

- Regular Safety Inspections: The equipment is subjected to regular safety inspections to ensure that all safety features are in working order. Any safety-related issues are addressed promptly to prevent accidents.

11. Comparison with Alternative Lifting Mechanisms

11.1 Hydraulic Lifting Mechanisms

Hydraulic lifting mechanisms are commonly used in some applications. However, they have several drawbacks compared to the proposed gear and pinion lifting mechanism:

- Complexity: Hydraulic systems are more complex, requiring additional components such as pumps, valves, and hydraulic cylinders. This increases the cost of installation, maintenance, and repair.

- Leakage Risk: There is a higher risk of hydraulic fluid leakage, which can cause environmental pollution and equipment damage. Regular inspections and maintenance are required to prevent leakage.

- Slow Response: Hydraulic systems may have a slower response time compared to the gear and pinion mechanism, especially during rapid height adjustments.

11.2 Pneumatic Lifting Mechanisms

Pneumatic lifting mechanisms also have their limitations:

- Limited Load Capacity: Pneumatic systems generally have a lower load capacity compared to hydraulic or mechanical systems. This restricts their application in heavy-duty die casting machines.

- Air Supply Requirements: A reliable air supply source is required, and fluctuations in air pressure can affect the performance of the lifting mechanism.

- Noise: Pneumatic systems can be noisy during operation, which may not be suitable for some work environments.

In comparison, the gear and pinion lifting mechanism offers a simpler, more reliable, and cost-effective solution for die casting machine control box height adjustment.

12. Case Studies and Field Applications

12.1 Case Study 1: Implementation in a Small Die Casting Factory

A small die casting factory implemented the proposed gear and pinion lifting mechanism in their production line. The results showed significant improvements in operator comfort and productivity. Operators were able to adjust the control box height easily, reducing fatigue and improving their work efficiency. The simple design and easy maintenance of the mechanism also reduced downtime and maintenance costs.

12.2 Case Study 2: Long-Term Performance in a Medium-Sized Die Casting Company

A medium-sized die casting company has been using the gear and pinion lifting mechanism for over a year. The mechanism has demonstrated excellent long-term performance, with no significant issues reported. The precise height adjustment and stable operation have contributed to the consistent quality of the die casting products. The company also noted a reduction in operator complaints related to control box height and ergonomics.

These case studies highlight the practical benefits and successful application of the proposed lifting mechanism in real-world die casting production environments.

13. Future Trends and Developments

13.1 Integration with Automation Systems

In the future, the gear and pinion lifting mechanism is expected to be integrated with advanced automation systems. This will enable remote control of the control box height adjustment, further improving the overall efficiency of the die casting process. Sensors can be incorporated to detect the operator’s height and automatically adjust the control box to the optimal position.

13.2 Use of Advanced Materials

The development of new materials with improved mechanical properties and durability will have a significant impact on the design of lifting mechanisms. Lightweight and high-strength materials such as carbon fiber composites may be used to reduce the weight of the mechanism while maintaining its strength and performance. These materials can also offer better resistance to wear, corrosion, and fatigue.

13.3 Smart Monitoring and Predictive Maintenance

Advances in sensor technology and data analytics will enable the implementation of smart monitoring systems for the lifting mechanism. These systems can continuously monitor the operating conditions of the mechanism, detect potential faults in advance, and schedule maintenance activities accordingly. Predictive maintenance will help reduce unplanned downtime and improve the overall reliability of the die casting equipment.

In conclusion, the gear and pinion lifting mechanism for die casting machine control boxes has great potential for further development and improvement. The future trends and developments discussed above will enhance its performance, functionality, and integration with modern manufacturing processes.