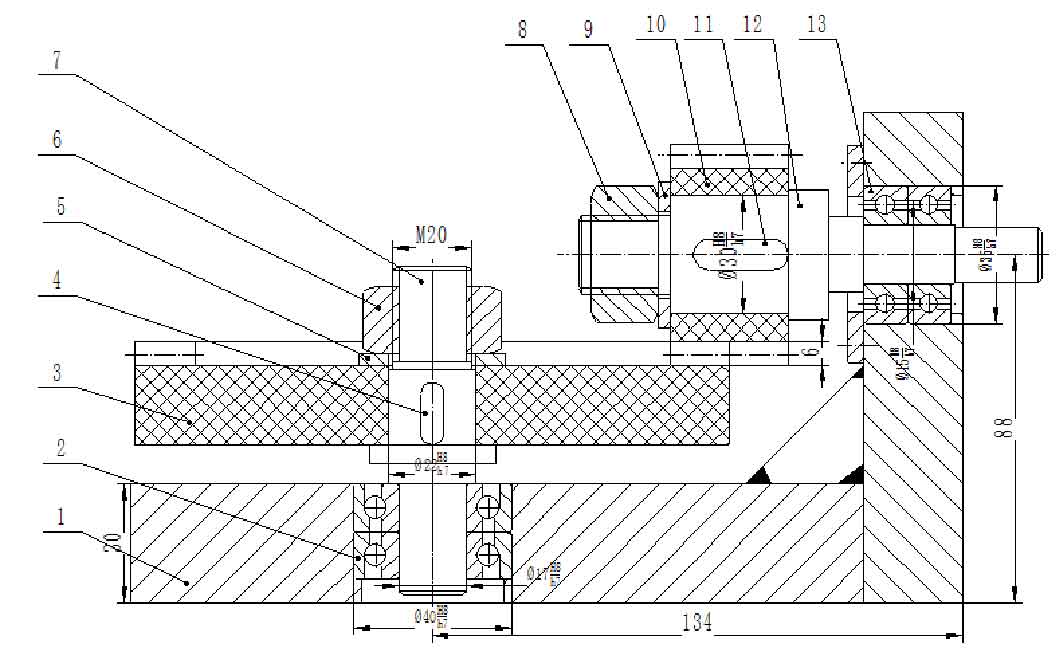

According to the theoretical knowledge of orthogonal helical gear, when the helical gear and helical cylindrical gear mesh, the two axes intersect vertically, so the design of the test-bed must meet this condition. According to this limitation, the test-bed device is designed. Figures 1 and 2 respectively show the assembly drawing of the meshing test-bed and the designed and installed transmission test-bed.

The design idea of the test-bed is: weld the two working plates together to form the bearing seat 3, and ensure the verticality requirements of the two working plates during welding; Bore two holes on the bearing seat to ensure that the axes of the two holes are vertical, so as to ensure that the axes of the two gears are perpendicular; One hole is used to assemble the driving shaft of helical cylindrical gear, and the other hole is used to assemble the driven shaft of helical gear. The angular contact bearing installed on the driven shaft is installed back-to-back, one side uses the shoulder on the bearing seat to locate the outer ring of the bearing, and the other side uses the shoulder on the shaft to locate; The face gear is circumferentially positioned by the key and compressed by the gasket and nut; The driving shaft transmits motion through the deep groove ball bearing, uses the shaft shoulder to locate the bearing inner ring, and the right end of the helical cylindrical gear is tightened with nut 9 to locate the helical cylindrical gear. Screw a M5 long screw at the right end of the driving shaft as the force input for the test.