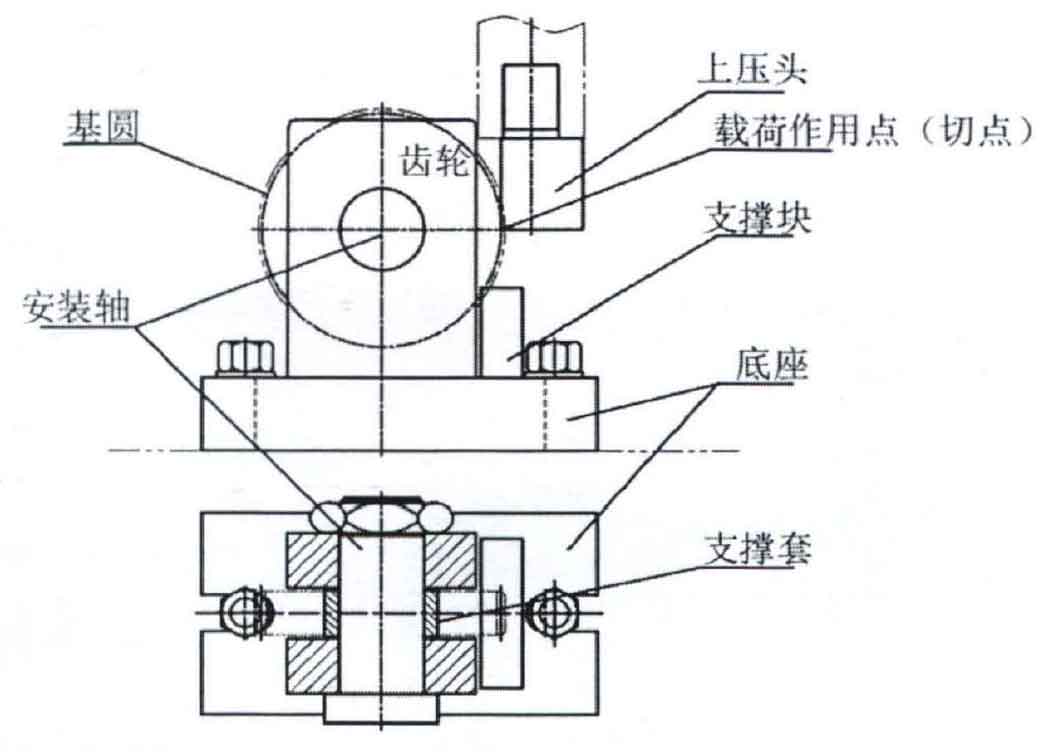

The test adopts the form of single tooth loading. It is necessary to design special fixtures according to the standard requirements to carry out tooth fatigue test. When designing the fixture, the following requirements shall be met:

1) The fixture must have enough stiffness to ensure the correctness of the gear installation position.

2) The fixture must ensure that the load action point does not deviate, and ensure that the load is applied on the top surface of the gear tooth;

3) The fixture shall be installed to ensure that the load direction on the gear teeth is tangent to the base circle of the test gear.

4) The fixture shall be installed to ensure the uniform distribution of load.

IIn order to meet the above requirements and ensure that the gears of all modules can be clamped, the test fixture can use the single tooth loading fixture because it can be adjusted. The fixture is shown in the figure. The fixture is mainly composed of a base, a mounting shaft, a support bracket, a support block, etc. the base is fixed with the workbench through two high-strength bolts, so that the force of the workbench fixture can be stably transmitted from the lower working face. The installation shaft is matched with the shaft hole of the gear to prevent the radial movement of the gear, and the fixing of the support sleeve prevents the axial movement of the gear. The support of the support block prevents the circumferential rotation of the gear. After the movement in three directions is limited, the gear is stably fixed on the workbench. The width of the upper indenter is greater than the tooth width. It moves downward and contacts the gear teeth. The cyclic load is applied to the gear teeth through the upper indenter. The vertical line of the action point of the overload load is tangent to the base circle of the gear.