In hot precision forging of driven bevel gear, the choice of die shape and size is very important. It not only affects the forming of gear teeth, but also affects the internal quality of forgings and the service life of forging dies. The following factors need to be considered when designing the mold:

(1) The bevel gear blank is easy to locate in the die cavity.

(2) Metal is easy to fill the tooth mold cavity.

(3) During the forming process, the metal flow path is short, and the metal of the bevel gear teeth mainly flows along the tooth profile to the tooth top.

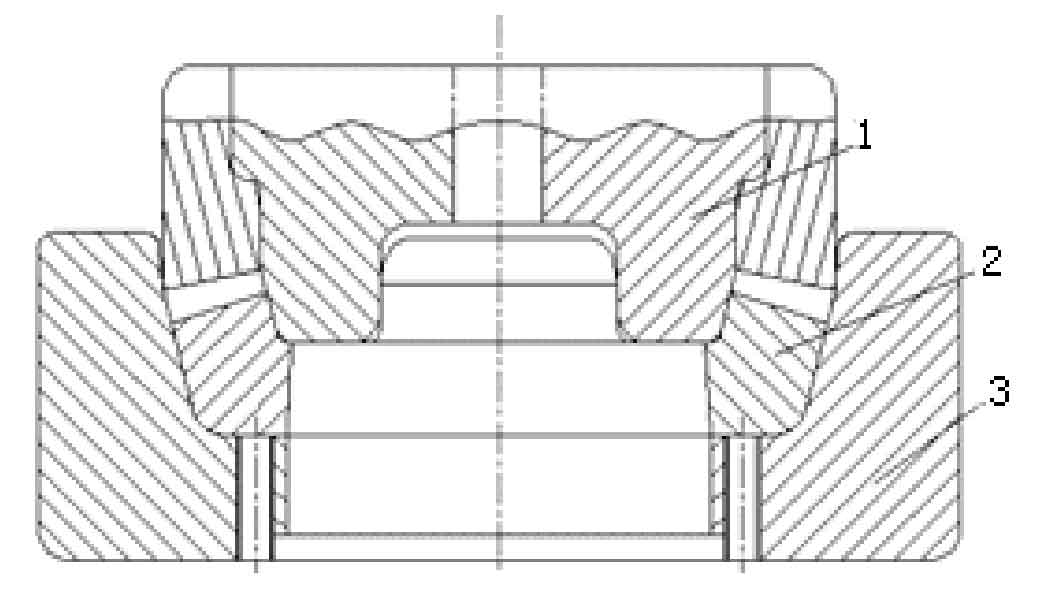

The punch of bevel gear processing is mainly used to transfer pressure and form tooth shape, and the die is mainly used to contain deformed metal and control metal flow. According to the forging forming requirements and the above principles, the die structure used to form the driven bevel gear in this paper is shown in the figure.

Die steel H13, i.e. 4Cr5MoSiV1, is selected as the die material. The allowable stress of this material is 1500MPa, which has good thermal stability, oxidation resistance and fatigue resistance. Its chemical composition is shown in the table.

| C | Si | Mn | Cr | Mo | V | P | S |

| 0.32~0.45 | 0.80~1.2 | 0.20~0.50 | 4.75~5.50 | 1.10~1.75 | 0.80~1.2 | ≤0.030 | ≤0.030 |