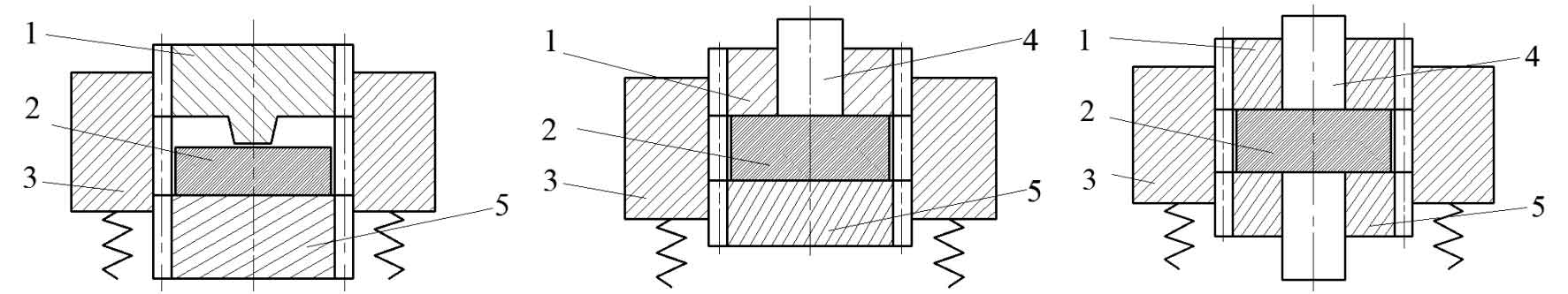

Three kinds of warm forging die structures are set according to the structural characteristics of spur gear. As shown in the figure, the floating die structure is adopted for all three schemes. Considering that the diameter of spur gear is large and the height diameter ratio and aperture ratio are relatively small, if the upper and lower punch adopt boss structure, the stress area is too small and the structure is unstable. In one scheme, the upper punch boss structure and the lower punch plane structure are set. During the forging process of spur gear, the upper punch goes down and the lower punch remains stationary. The upper and lower punch and the female die form a closed die cavity. After the processing, the punch goes up and returns to the original position. The ejector will eject the forging. The forging process of spur gear is completed. This scheme can be realized on the double action press.

(b) Unidirectional upsetting extrusion of floating die

(c) Two way upsetting extrusion of floating die

1.Upper punch 2 Blank 3 Floating die 4 Upper extrusion punch 5. Lower punch

The second scheme is to change the upper punch of the first scheme into the upper upsetting die and the upper extrusion die. At the beginning of the forging of spur gear, the two move at the same time. Due to the design of spur gear skin connection, the upsetting distance is short and stops when it reaches the height of pre forging, and the filling of the whole tooth shape is formed by the extrusion movement of the upper extrusion die.

In the third scheme, the upper and lower punch are changed into upsetting punch and extrusion punch. The forging process of spur gear consists of two parts. During the forming process, it is necessary to control the downward upsetting movement of the upper upsetting punch and the upper extrusion punch. After reaching the specified stroke, the upper pier roughing punch is controlled to stop, and the upper and lower extrusion punch make relative extrusion movement. After the forging of spur gear is completed, the upper upsetting and extrusion punch are reset, and the lower extrusion punch ejects the forging, Then reset. The forming equipment needs to be a double acting hydraulic press up and down, which is called compound hydraulic press for short.