The main error items of gear are: base pitch deviation Δ FPB, tooth profile error Δ FF, tooth alignment error Δ f β, etc. Among them, the base pitch deviation Δ FPB and tooth profile error Δ FF are the main errors of gear. Since these two errors are random variables which obey normal distribution, the system equivalent error is obtained by combining the base pitch deviation Δ FPB and the tooth profile error Δ FF according to the statistical method

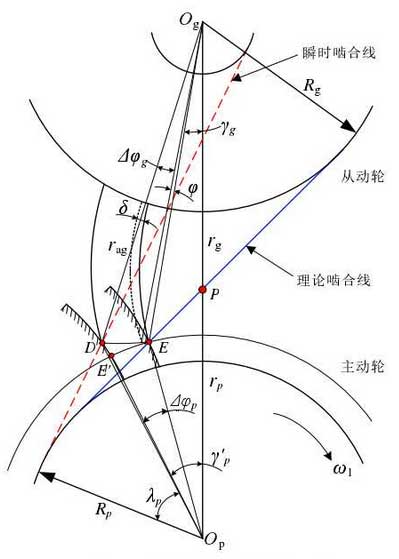

The deformation caused by the load of the gear is also an important factor affecting the actual meshing point position of the gear. In general, the gear system equivalent error and load deformation are numerically combined to obtain the comprehensive gear deformation.

However, due to the high coincidence degree of the helical gear system studied in this paper, there are 3-tooth meshing area and 4-tooth meshing area, and there is coordination and restriction relationship between the meshing tooth pairs, so the above method is not accurate enough. Therefore, this paper uses LTCA analysis program to calculate the gear load-bearing comprehensive deformation δ more accurately, which can be used as the basis for calculating the initial position of meshing impact. The diagram shows the principle diagram of out of line engagement impact