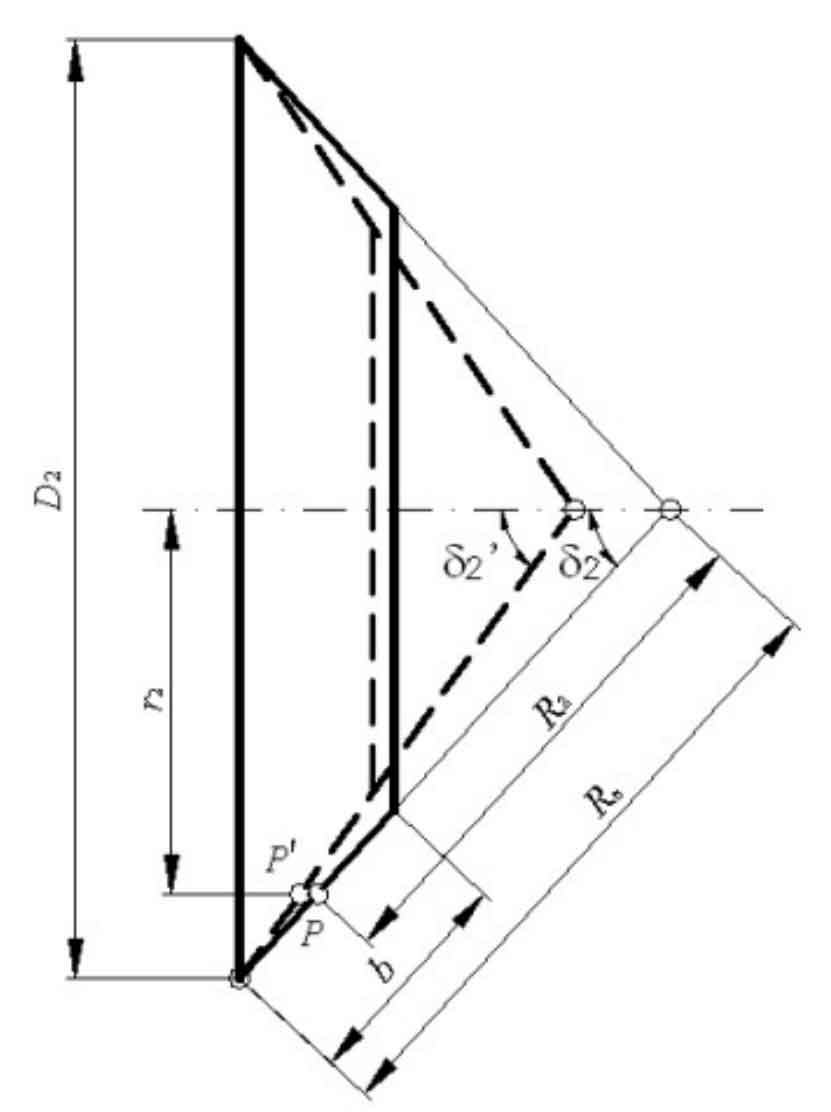

The pitch diameter D2 of the large gear of the hypoid gear pair is directly related to the size of the drive axle housing. Excessive D2 affects the ground clearance of the axle housing, and the geometric relationship between the pitch diameter D2 of the large end of the large gear and the tooth width b of the large gear is not directly described in the Gleason algorithm. To take the relationship between the above two parameters as a condition for solving the equations, we must first establish the functional relationship between them. The figure shows the estimation of pitch cone radius of large gear of hypoid gear pair.

According to the geometric relationship in the figure, the position of the big gear node P can be determined by the pitch circle radius R2 of the big gear, the pitch circle diameter D2 of the big end of the big gear, the tooth surface width b of the big gear and the pitch cone angle of the big gear δ 2 means:

Because the pitch cone angle of the large gear in the hypoid gear pair is slightly smaller than that of the spiral bevel gear, Gleason algorithm recommends to preliminarily calculate the pitch cone angle of the large gear through the formula δ 2 。

By solving the mathematical model of Gleason hypoid gear, the node position of large gear is obtained. Under the condition that the node radius and tooth surface width of the big gear do not change, the pitch cone angle of the big gear is determined by δ’ Become δ After 2, the position of the big gear node is no longer located at the midpoint of the big gear tooth width, but moves to the small end.