The role of bevel gear die in the process of metal plastic forming is huge. In the process of metal plastic forming, it is necessary to apply load to the blank through the die to make the bevel gear blank metal produce plastic deformation. In this process, the die and metal squeeze each other, resulting in the metal flow of bevel gear blank in the die cavity, so the structure and shape of the die have a great impact on the metal flow. Reasonable die structure will make it easier for the blank metal of bevel gear to fill the whole cavity, avoid machining defects and improve the quality of forgings.

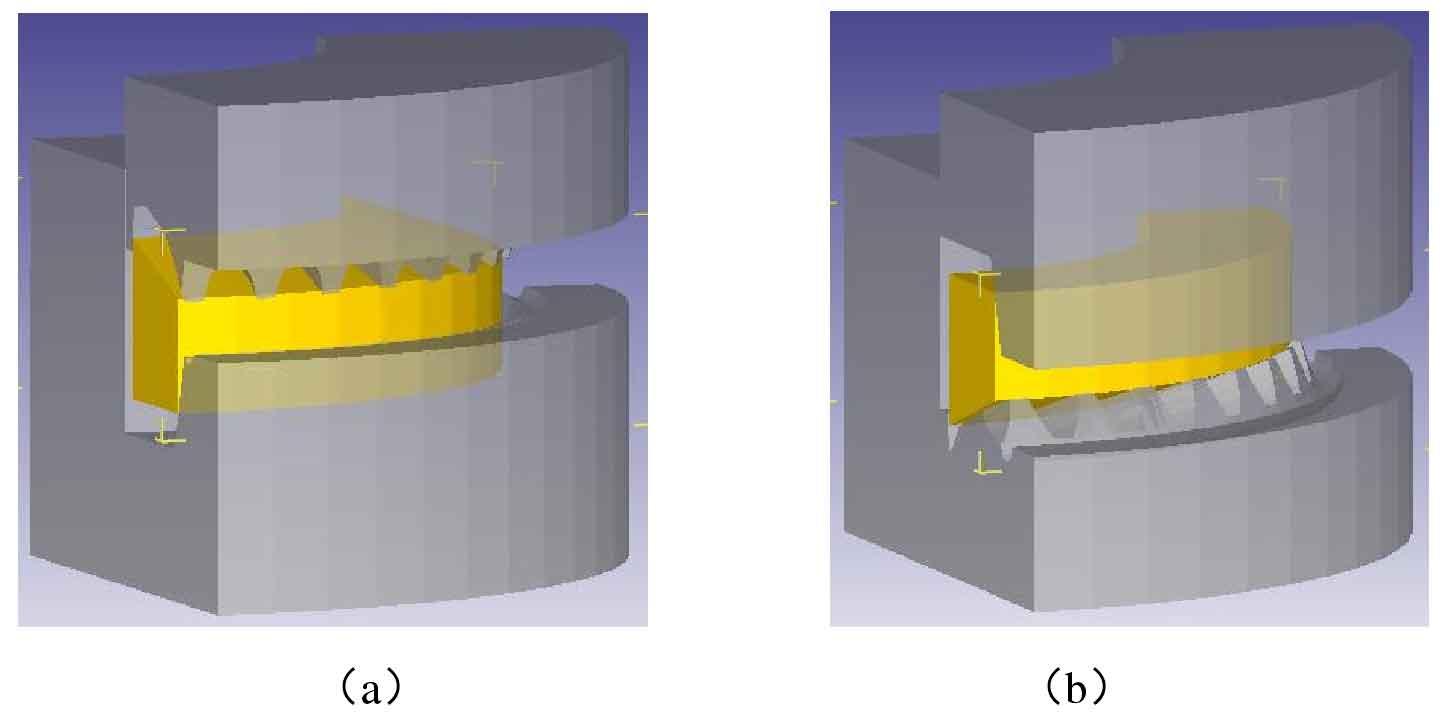

The research object set in this group of experiments is the structure of the die. The forging temperature is set at 800 ℃, the size of the bevel gear blank is 125 mm inner diameter, 170 mm outer diameter, 175 mm and 180 mm high, 36.8 mm, 33.5 mm and 30.8 mm respectively, the cone angle of the upper or lower surface is 18 °, the movement speed of the upper die is set at 12.5 mm / s, and the structure of the bevel gear die is shown in figure (a) (b).