The failed diesel engine was installed on the fishing boat, with the power of 198 kW and the working speed of 750 rpm. After 700 hours of operation, the gear of the rudder gear broke and the diesel engine was damaged. The gear material is 45 steel, and the gear manufacturing process is forging, normalizing, roughing, tempering, finishing, hobbing, tooth surface quenching and grinding. After the accident, the gear was removed, and several teeth were found to be broken from the gear, and a large piece was dropped.

The gear fracture of the diesel engine belongs to multi-source fatigue fracture. The main cause of fatigue is due to improper control of heat treatment process, unhardened tooth root and tooth flank, and the microhardness measurement result is only hrc26 ~ 28. Therefore, the fatigue strength of tooth root material is far lower than the design requirements, and the working stress at the tooth root is higher, which results in early fatigue fracture at the tooth root.

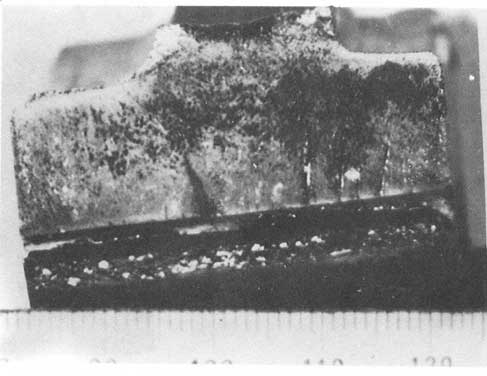

The fracture morphology of the falling block on the gear. Shell like striations can be observed on the fracture surface. There are many macro fatigue step striations in the crack source area, and the crack source is produced at the root of teeth, and there are many fatigue sources.

The macromorphology of the other section of the block falling in the figure above,

It also has the characteristics of macro fatigue step, shell stripe and multi-source. In addition, there are serious rust spots on the fracture surface due to improper fracture protection.

One of the several broken teeth dropped on the gear also has the characteristics of shell like stripe, fatigue step and multi-source.

SEM observation of the fracture shows that the crack originates from the surface of the tooth root, and the step stripe of the crack extending inward can be observed.