Dr. Stadtfeld of Greenson first outlined the idea of machining face gear with dished grinding wheel. The use of dished grinding wheel to grind face gear has the advantages of simple structure of grinding wheel, convenient design, manufacture and dressing, not limited by the design parameters of face gear, easy realization of machine tool movement and so on. Due to the relative maturity of worm tool machining face gear abroad, there are few public reports on the research of disc tool machining face gear abroad, but it has been greatly developed in China because it is easy to realize.

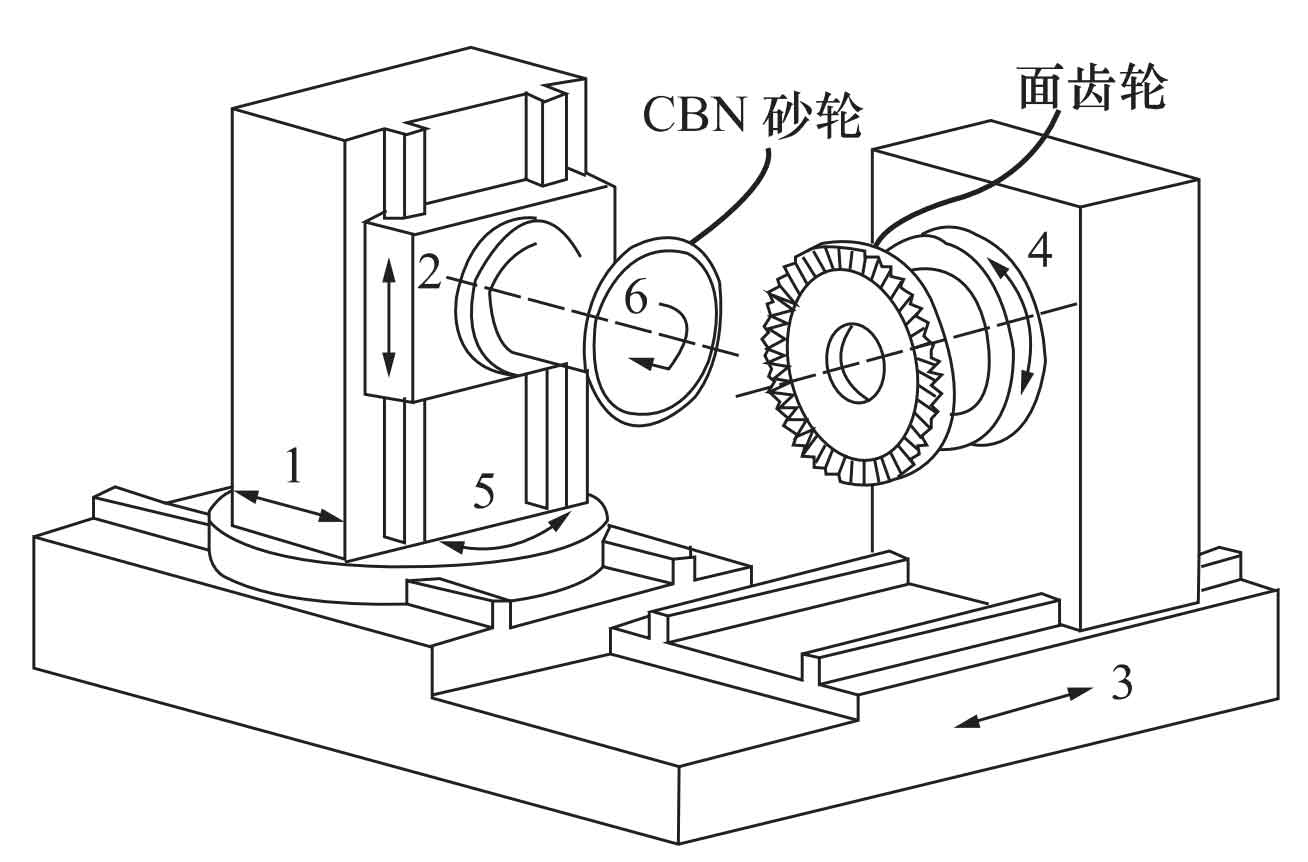

The principle of machining face gear with dished grinding wheel is shown in the figure, in which the generating surface of the tool is formed by the rotation of the normal section of the generating wheel around the axis of the tool. The tool and workpiece move linearly along the guide rails 2 and 3 to complete the feed movement in the direction of tooth width and tooth depth respectively. The tool rotates 6 around its own axis to realize the cutting movement. In addition, the combined movement of linear motion 1 and 3 and rotary motion 5 can make the tool rotate around the axis of the production wheel. The rotation and the rotation of the workpiece simulate the engagement between the production wheel and the workpiece, So as to complete the generation processing of face gear.

The workpiece is in point contact with the dished tool, and belongs to single tooth indexing processing and needs tooth feed movement, so its processing efficiency is very low. Nevertheless, due to its realizable convenience, its outstanding significance is that it can realize the cutting and grinding of face gear in a short time. If it is used for gear grinding, the tool also needs to be trimmed. However, if the tool is covered with hard cubic boron nitride, the dressing of the tool can be reduced, and even the dry grinding gear can be realized, which is also in line with the sustainable development goal of gear manufacturing technology.

Based on this manufacturing technology, China has made great progress. For example, Li Daqing realized the two-way shape of face gear by using dished grinding wheel and improved its meshing characteristics. Guo Hui et al. Studied the NC interpolation method based on dished tool, the experiment proved that the interpolation algorithm is effective, and put forward the prediction model of predicting envelope residual. Wang Yanzhong et al. Studied the 5-axis NC method for milling face gear with dished cutter, and the experiment proved that the maximum manufacturing error was 22.6 μ m. The precision grinding method and the dressing method of dished grinding wheel are developed, and the tooth surface deviation is further reduced through error compensation. Tang Jinyuan and others studied the grinding teeth and shape of face gear based on dished grinding wheel, and simulated it with simulation software. Recently, Fang Zongde and others have carried out research on the grinding and shaping of offset surface gears with dished grinding wheels.