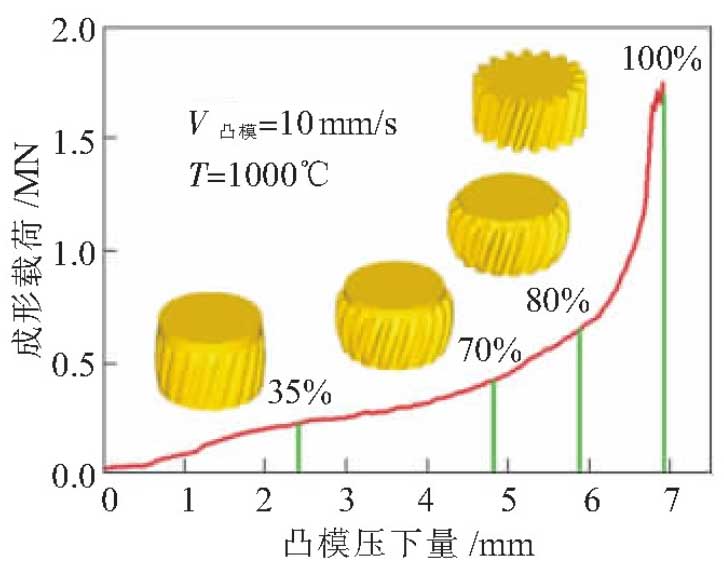

The figure shows the load stroke curve of the cylindrical helical gear during hot forging.At the early stage of forming, the blank begins to deform and the load curve increases slowly.

At the later stage of forming, the billet deforms greatly and the load curve increases sharply.This is because the stress and deformation of the metal in each part of the blank becomes complicated in the later forming stage.

According to the change trend of load-stroke curve, the deformation process is divided into four stages, and the hot precision forging process of cylindrical helical gear is analyzed in stages. The corresponding punch reduction of the split point is 35%, 70%, 80% and 100% respectively.When the reduction amount is 35%, the blank fills into the circle of the tooth root of the cylindrical helical gear; when the reduction amount is 70%, the blank fills into the indexing circle of the concave die; when the reduction amount is 80%, the blank contacts the part of the tooth root of the concave die; when the reduction amount is 100%, the forming process is completed.