1. Test purpose

Verifying the rationality of bevel gear process is an effective guarantee to reduce the heat treatment deformation of bevel gear;

2. Test object

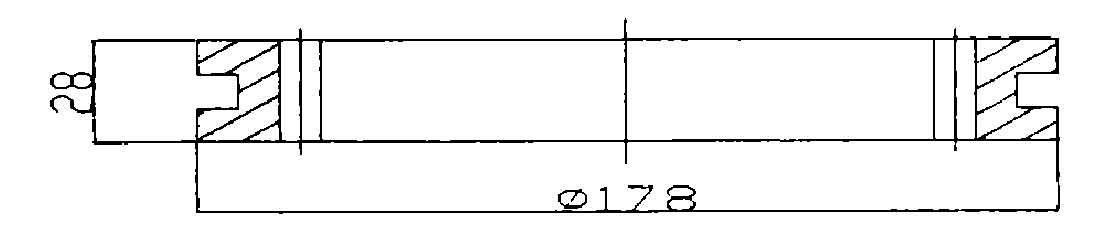

We selected the representative of thin-walled parts that are most sensitive to bevel gear technology: 9t 3456 speed gear sleeve (drawing No. 1701357-4e material 20CrMnTiHA3) as the test object. The processing route of the part is: forging ~ pre heat treatment – rough and finish machining – carburizing, quenching and tempering – shot blasting – a small amount of grinding. The pre heat treatment of the part is isothermal normalizing. We mainly test the heat treatment deformation of bevel gear under different process conditions.

| Name | Drawing No. | Material Science | Internal tooth modulus | Number of teeth | Accuracy |

| 3456 speed gear sleeve | 1701357一4E | 20CrMnTiHA3 | 6 | 51 | 6 grade |

3. Test conditions and bevel gear process parameters

Carburizing equipment: still aichelin4-2 multipurpose furnace;

Process conditions: comparison of deformation under different bevel gear process conditions;

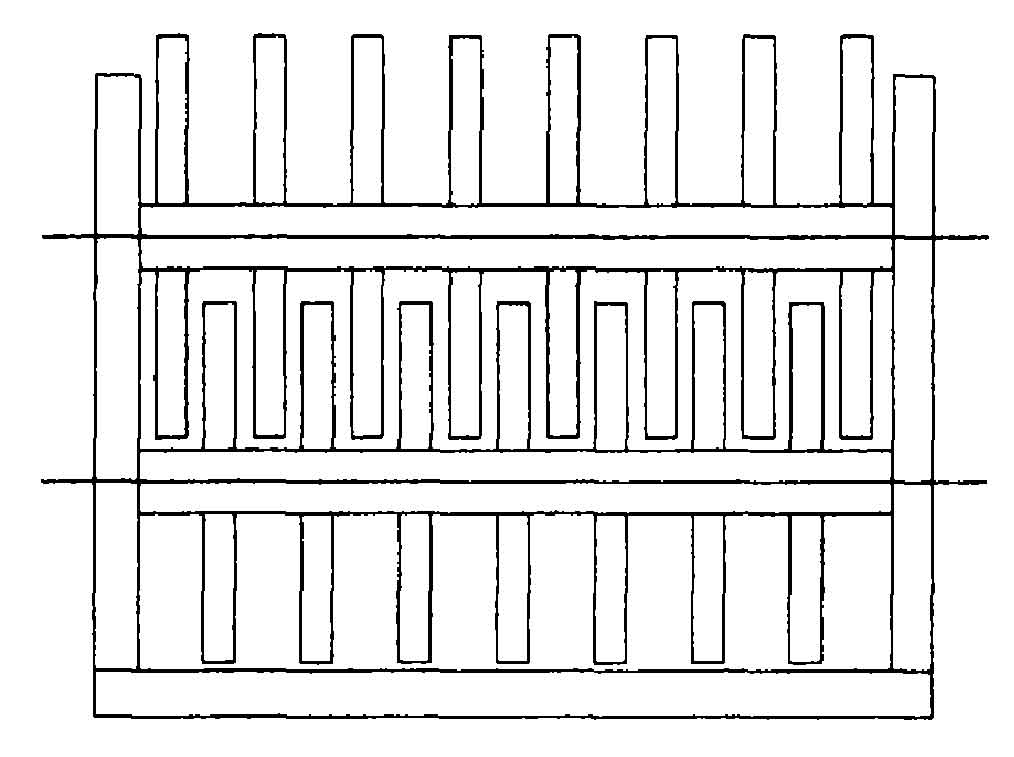

Comparison of charging methods: hanging and Paperback: see Fig. 2 and Fig. 3;

Comparison of process methods: carbonitriding and carburizing (see Table 1 for process parameters of bevel gear);

Comparison of different cooling conditions: slow mixing and fast mixing of quenching oil during cooling after carbonitriding (the specific bevel gear process is the same as the carbonitriding parameters in Table 2);

| Section | Temperature rise and insulation | Temperature and carbon potential | Strong infiltration | Spread | Cooling and carbon reduction potential | Quenching oil temperature | Tempering |

| Temperature (℃) | 850 | 930/880 | 930/880 | 930/880 | 830 | 120 | 200 |

| Carbon potential (%) | 0.4 | 0.6 | 1.2/1.1 | 0.9 | 0.8 | — | — |

| Time (h) | 0.5 | 0.5 | 2.5/3.5 | 2/2.5 | 0.5 | — | 4 |

The deformation of the gear sleeve parts in the above states, in order to find out the reasonable bevel gear process conditions and parameters, and achieve the deformation of the gear sleeve parts in the above states, in order to find out the reasonable bevel gear process conditions and parameters, and achieve the purpose of controlling the heat treatment deformation of the gear sleeve.