Damping is an inherent characteristic of dynamic contact problems. Damping will lead to energy dissipation and the attenuation of free vibration amplitude with time. Therefore, in the case of dynamic contact, damping must be considered. In ABAQUS explicit dynamic analysis, damping coefficients are usually set in the model to ensure the stability of the numerical algorithm.

Five analytical models are established to study the effect of material damping on the dynamic performance of spiral bevel gears. The size and shape of the model have not changed, and the mass scale factor of the model has been changed. The scale coefficients of the model are 300, 500 and 700, and the other parameter settings and load conditions in the pretreatment have not changed.

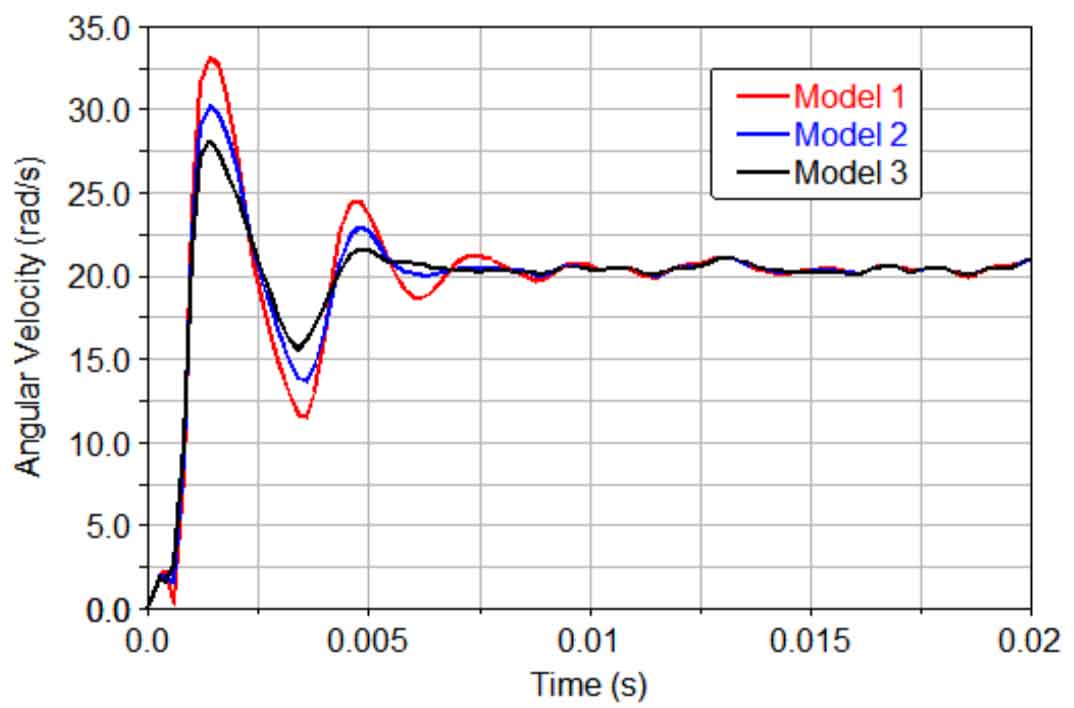

As shown in Figure 1, the speed history curves of the three models are shown. It can be seen that due to the impact of initial impact and load, the rotational speed of the big wheel will take some time to stabilize. Compared with these five models, the time required for large wheel stabilization is different. It is stable at 0.01s, 0.0072s and 0.0074s respectively, but the stable value after stabilization is almost 20.43rad/s.

It can be seen that damping does not affect the stability value of large wheel speed, but has a great impact on the stability time of the initial spiral bevel gear transmission. With the increase of damping, the spiral bevel gear meshing transmission device will soon stabilize, but there will be slight fluctuations after stabilization, which is consistent with the actual transmission situation of spiral bevel gear. Damping plays a positive role in improving the vibration of spiral bevel gear transmission. The greater the damping, the smaller the amplitude of the speed time-history curve of the big wheel, and it can enter a stable speed change state as soon as possible.

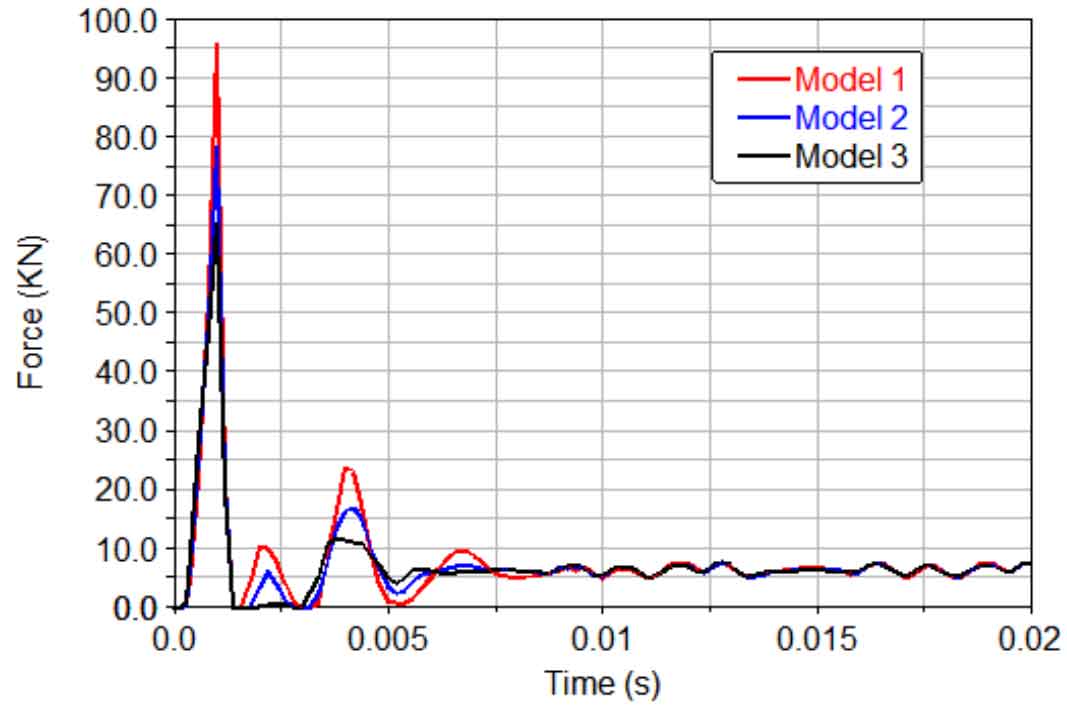

From the time history curve of contact force (Fig. 2), it can be seen that in the early stage of spiral bevel gear transmission, the contact force fluctuates greatly and decelerates slowly with the passage of time, finally reaching a stable value. If the damping is different, the maximum and stable values of contact force are different. The time required to reach the stable value is approximately the same as that required to reach the stable value of the main wheel speed.

It can be seen that the reason for the fluctuation of contact force is also the instability of the transmission device. Through analysis and comparison of these three sets of curves, the maximum values of the time-history curve of the tooth contact force are 95.94 kN, 78.27 kN, and 65.35 kN, and the tooth contact force after relatively stable meshing transmission is 6.21 kN, 6.37 kN, and 6.30 kN. Therefore, damping will affect the amplitude and stability of the time-history curve of the contact force on the gear tooth surface, and both will decrease with the increase of damping.