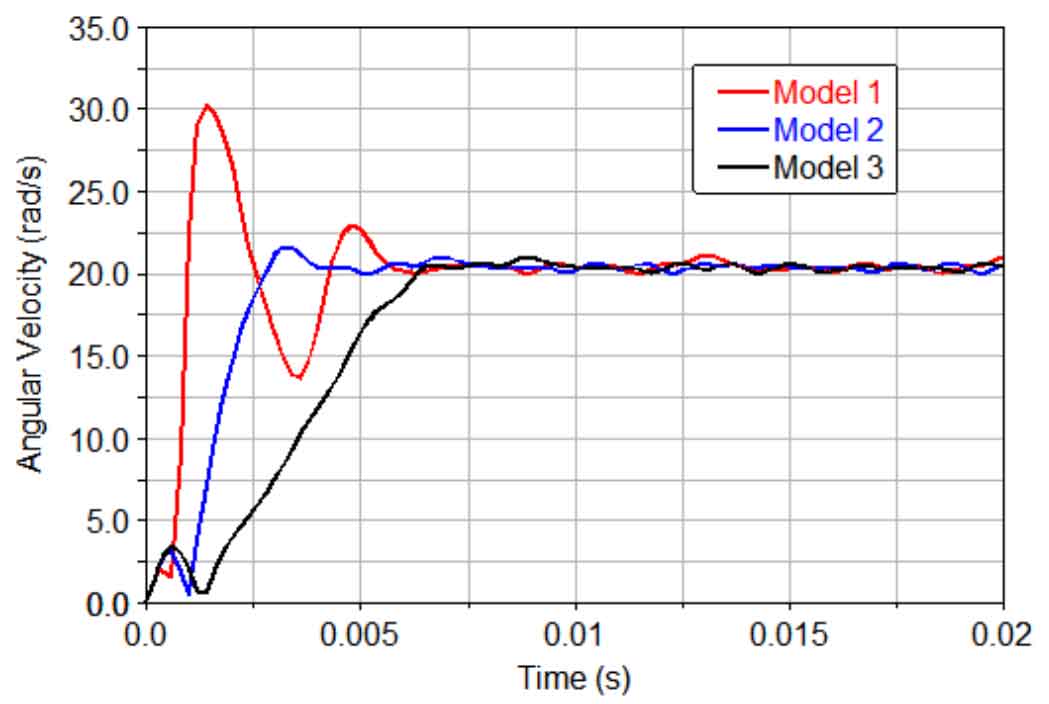

Whether the acceleration time of the main wheel will affect the dynamic meshing performance of spiral bevel gears, and whether changing the acceleration time of the main wheel will affect the speed change of the main wheel. Therefore, the speed of the small wheel is set to 80rad/s, and the acceleration time is 0.001s, 0.003s, and 0.007s respectively. Other parameter settings and load conditions in the pretreatment are unchanged.

Figure 1 shows the speed history curve of the three models. It can be seen that due to the influence of the acceleration time of the small wheel, the rotation speed of the big wheel will be stable after a period of time. Comparing these three models, the speed of the big wheel tends to be stable at 20.43rad/s at t=0.0072s, 0.005s and 0.008s, and the amplitude and frequency of the speed fluctuation of the big wheel decreases with the increase of the acceleration time. For model 1, the loading time is too short, the initial meshing impact is large, and too much initial impact will seriously affect the life of spiral bevel gears. Compared with model 1, the speed range of big wheel of model 3 changes smoothly and the speed curve becomes smoother.

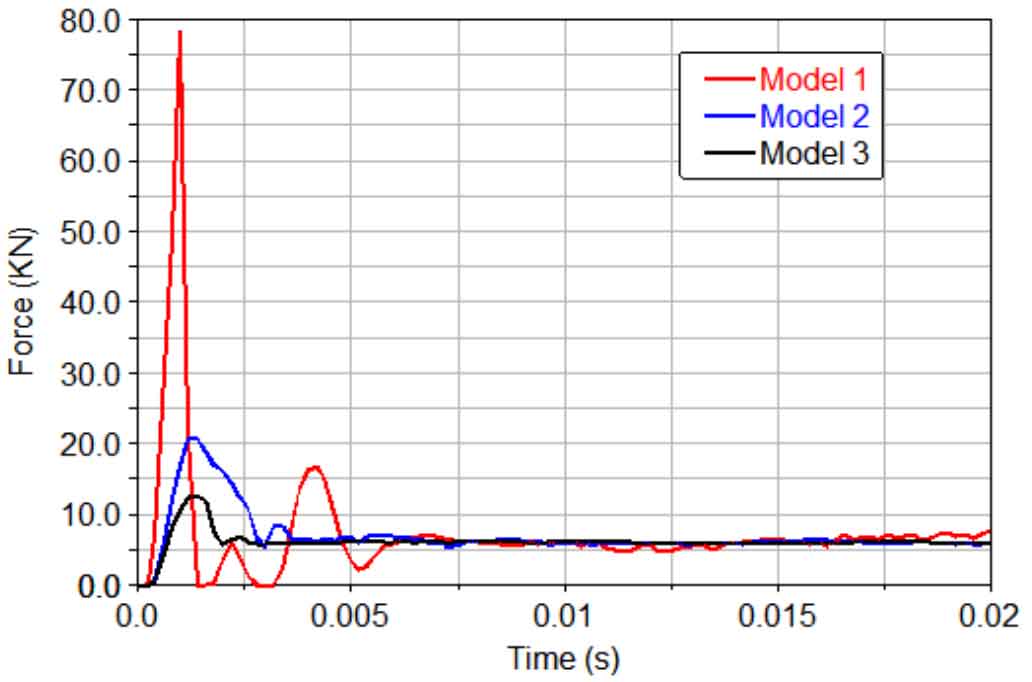

By analyzing and comparing the three sets of curves in Figure 2, the acceleration time has a great impact on the contact force. The maximum value of the time-history curve of the contact force on the tooth surface is 78.26kN, 20.82kN and 12.61kN respectively, and the maximum contact force at the peak value is reduced by 73.39% and 39.43% respectively. Therefore, the longer the acceleration time, the smaller the maximum impact force and the shorter the time to enter the stable speed. The increase of the peak contact force is attributed to the initial impact, and the contact force changes periodically in the initial short time, resulting in greater vibration.