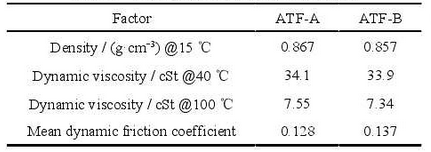

In addition to the lubrication of gears and bearings, ATF is also used for the lubrication and cooling of hydraulic control oil, clutch and other components, as well as the control of operation stability [49]. In recent years, due to the improvement of control system accuracy and sliding performance of automatic transmission, the lubrication of gear system by oil products is facing great challenges. The table shows two different oil products of automatic transmission.

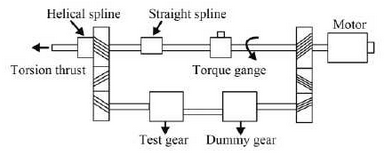

Composite shot peening and manganese phosphate chemical treatment are respectively carried out for the helical gear used for the test, as shown in the figure is the dynamic cycle gear fatigue test-bed.

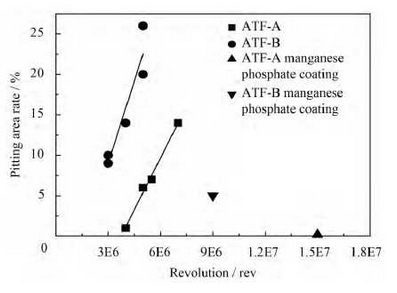

The commonly used working temperature of ATF in transmission is usually between 80 ~ 110 ℃. The fatigue pitting rate of gear under the contact stress of 1 730 MPa is measured under the working oil temperature of 80 ℃. The result is as shown in the figure. The fatigue pitting area rate of gear to a is smaller than that of gear to B.

The figure shows the wear amount at the bottom of the gear. The driving pinion of the gear pair a is much larger than the driving pinion of the gear pair B. The experimental results show that the gear wear is inversely proportional to the pitting rate.