The contact characteristics of the cylindrical gear at each meshing time are equivalent to the cylindrical contact with corresponding curvature. If the tooth surface modification and boundary effect are not considered, it is a typical Hertz line contact, and the contact area is a narrow strip, in which each section has the same contact characteristics. Therefore, the contact problem of the cylindrical gear can be simplified to a two-dimensional contact problem. Although the simplified model is different from the actual cylindrical gear contact state, the pressure and friction solved based on relevant theoretical methods still have considerable guiding significance for the contact and stress analysis of cylindrical gear pairs.

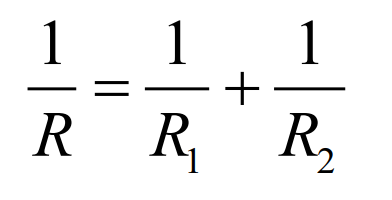

Based on the principle of equal contact clearance, the cylindrical contact is further approximated as the contact between the cylinder and the plane, where R is the radius of the approximated cylinder, which is calculated by the following formula:

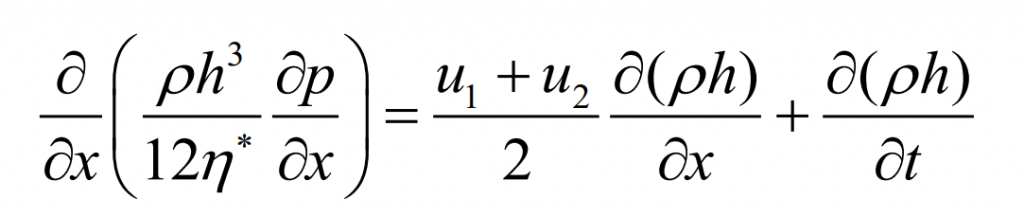

The pressure at the contact interface is calculated by Reynolds equation. In order to simplify the calculation process, the contact of straight cylindrical gear can be regarded as two-dimensional line contact. The constitutive equation is as follows:

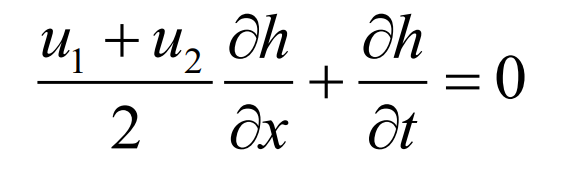

Mixed lubrication is easy to occur under extreme working conditions such as low speed and heavy load. At this time, Reynolds equation can not fully express the pressure distribution, which is expressed by the following formula:

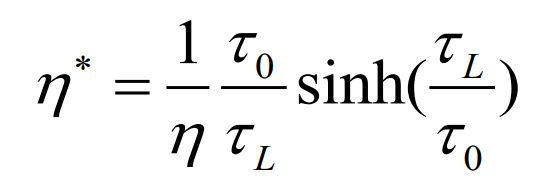

The effective viscosity of lubricating oil can be calculated by the following formula: