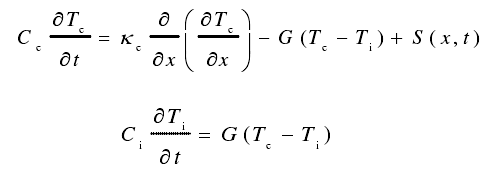

In the study of femtosecond laser ablation of 20CrMnTi gear material, the two temperature model is used to study the interaction between photon and electron, electron and lattice. It is confirmed that single pulse laser can efficiently ablate and remove the laser energy of material. The two temperature model can be expressed as follows:

Where CE is the electron heat capacity; te is the temperature of the electron system; t is the time; κ e is the electronic thermal conductivity; X is the distance perpendicular to the material surface; G is the coupling coefficient of the electron and the lattice, which is the characteristic parameter of the energy interaction between the electron and the lattice; Ti is the lattice system temperature; s (x, t) is the heat source term corresponding to the laser pulse; CI is the lattice heat capacity.

Equation (1) represents the change law of electron temperature with time, and formula (2) represents the change rule of lattice temperature of gear material with time. In the femtosecond time scale, the energy transfer between lattices is ignored.

The energy distribution of laser Gaussian beam is shown in the figure. The femtosecond pulse laser of this light source does not need to consider the distribution of laser pulse energy on the width, which can simplify the calculation difficulty.

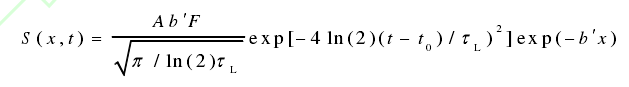

The expression of heat source term s is as follows:

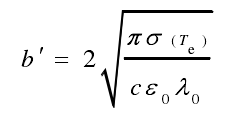

Where a is the extinction coefficient, B ‘is the absorption coefficient of the gear material, f is the laser energy density, γ L is the femtosecond laser pulse width, t0 is the initial pulse time.

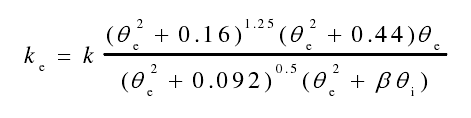

The electronic thermal conductivity Ke is generally considered to be a constant. When femtosecond laser irradiates the metal surface, the electron temperature will exceed the Fermi temperature

Where k is the thermal conductivity of the material, θ e is the ratio of electron temperature to Fermi temperature, θ I is the ratio of lattice temperature to Fermi temperature, and β is the constant of electronic thermal conductivity material.

When the electron temperature is low, such as nanosecond laser ablation, the absorptivity of gear material can be regarded as a constant. In the process of femtosecond laser ablation, the electrons on the surface of the material are heated to high temperature and high pressure. When the energy absorbed by the tooth surface is large enough, the absorption coefficient and absorptivity of the material change dynamically. Therefore, in the establishment of femtosecond laser ablation model, the dynamic change of absorptivity should be considered. The absorption coefficient of the material is related to the temperature coefficient of resistance, wavelength and temperature of the material.

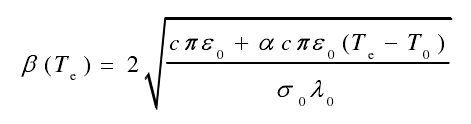

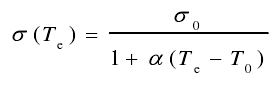

Where C is the laser propagation velocity, ε 0 is the vacuum dielectric constant and λ 0 is the laser wavelength. Under the condition of laser radiation, σ (TE) is a linear function of the temperature of the electronic system

Where σ 0 is the conductivity of the material at 300 K, α is the temperature coefficient of the resistance of the material, and t0 is the initial temperature of the material without ablation.

When femtosecond laser irradiates the material vertically, the absorptivity of gear material is mainly related to the temperature coefficient of resistance, laser wavelength and tooth surface temperature.