High-speed dry hobbing is a new technology for gear machining,It is an efficient manufacturing process for machining spur and helical gears.However,High-speed (spindle speed 1200r/min) cutting speed fluctuation is large, especially for helical gear machining, which requires two sets of electronic gearboxes for multi-axis synchronous control.Therefore, the machining error compensation of helical gears isIt is of great significance to improve the machining accuracy of helical gears.The accuracy of hobbing is affected by many factors, including tool errors,Installation error, thermal error, servo error, and synchronization error of multi-axis linkagebadlyThe main influencing factor is the synchronization error.Reducing gear machiningThere are mainly two methods of error prevention, namely error prevention and error compensation.repayment methodThe error prevention method mainly improves the accuracy of assembly parts,to reduce the machining error, but with the increasing demand for machining accuracy,The cost of error prevention methods also increases exponentially.Compensation method is a commonly used method in gear machining processhave becomeThis low-cost, high-efficiency, flexible error compensation feature only requires oneThe error value is calculated according to the error compensation model, and then compensated by backward compensation.Reducing processing errors is an advantage that error prevention methods do not have.HanAccording to the processing principle of worm wheel grinding machine, through the homogeneous transformationThe transformation matrix for establishing the coordinate system between the kinematic pairs is used to correct the linkage error of each axis.Decoupling, error compensation through electronic gearbox to achieve expected compensationeffect, using software to achieve error compensation canIn terms of component manufacturing costs, improving manufacturing accuracy.ThroughAnalyze the error data of the machine tool under different temperature conditions, and establish a geometric error model.Comprehensive mathematical model of polynomial fitting and linear fitting for difference and thermal errortype, applying a comprehensive error compensation system for error compensation.HSU andWANG[7] Use computer-aided manufacturing to correct the position and orientation errors of the cutting toolThe post-processing system of Computer-Aided Manufacturing (CAM)The errors of the rotating axis and the linear axis are added to the NC code separatelyCompensation.Through collecting multiple sets of experimental data, establish error factors andThe neural network mapping model between error values can also achieve error valuesprediction and compensation.By establishing a relationship between gear M value and temperatureRBF neural network thermal error compensation model for numerical control worm sandEffective verification was conducted on the wheel grinding machine.Using fuzzy clusteringClass algorithm, establish temperature and thermal error compensation model, improve gearThe accuracy of the neural network error prediction model depends on the accuracy of the training data.The accuracy of field data collection.Starting from the source of collected data,The signal processing method obtains purer data and can establish more accurateHigh error compensation model.Using wavelet algorithm for longThe dynamic error of the grating measuring machine was successfully decomposed.During the measurement of cutting force, it is easily affected by the inherent frequency of the instrument and the surrounding environment.and other factors, developed a compensation technique based on Kalman filter.dynamic compensation for the cutting force during the machining process.The processing method does not perform multi-resolution analysis on the collected data, which is universal.Not very sexual.The wavelet packet transform method overcomes the limitations of traditional methods and can be used toMulti-resolution analysis of signals not onlyStill heresignal feature extraction and other fields.Due to the hobbing processThe initial complex motion state of components and the impact of changing environmental factors during the processIt is difficult to express the nature in time domain with specific functional expressions, but the processing processThe corresponding spindle current, vibration, noise, temperature and other signals in the frequency domainThe internal gear cutting process will exhibit regular characteristics.Difficulties in compensating for synchronization errors caused by unstable processing conditionsThe author of this article uses the wavelet packet algorithm to analyze the collected synchronization error signalMulti-resolution analysis is conducted, and error feature identification is performed based on the principle of synchronous error formation in hobbing helical gears. Interference noise is discarded, and the hobbing process is reconstructed.According to the principle of error superposition, the reconstructed errorThe difference decoupling is compensated to the software axis separately to achieve accurate compensation for errors.

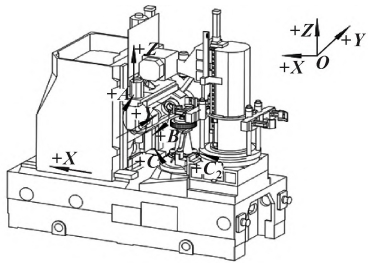

Structure of hobbing machine tool and motion relationship of each axis

The YK3126 hobbing machine has a total of 6 control axes (excluding the robot armThe rotation axis C2) is composed of three moving axes X, Y, Z and three rotation axesconsisting of shafts A, B, and C, which can be driven separately by six motors, eachThe functions of the servo axis are: the X axis is a radial axis, which controls the radial direction of the hobCutting depth;Y-axis is the tangential axis, used for tool creep and extending the use of the hobLifespan;Axis Z is the axial feed axis, which controls the axial movement of the hob, fromAnd the complete tooth width is processed;the A axis is the pitch axis of the machine tool, which can be adjustedInstallation angle of the hob;Axis B is the rotation axis of the hob, also known as the spindle;The C axis is the rotation axis of the workpiece.When machining a spur gear on a hobbing machine, the hobbing process is only B-CWhen machining helical gears, in addition to the B-C axis linkage,It requires the linkage of the Z-C axis, therefore, during the machining of the helical gear, the driven shaft CThe linkage relationship of the axis is shown in the formula。

Composition and acquisition of synchronization error signal

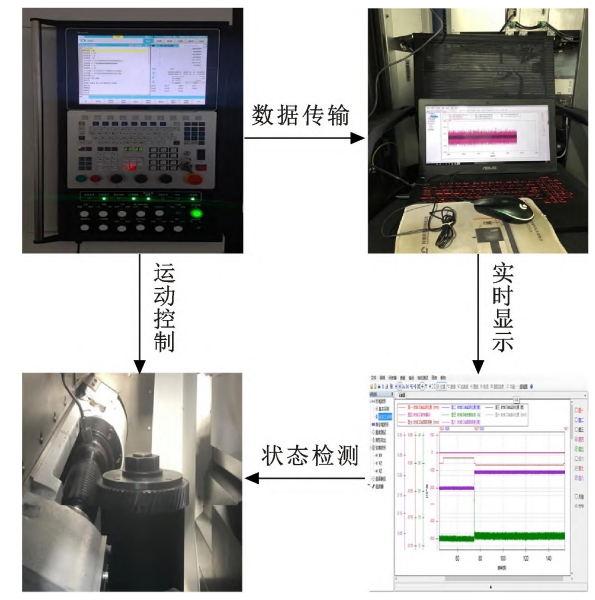

Due to the structure of the high-speed dry hobbing machine and the characteristics of helical gear machining,Arts are extremely complex. During the process of machining helical gears, the tool holder, hob, and straightThe motion of key components involved in the formation of helical gears, such as the drive motor, belongs toNon-stationary, non-linear complex motion process.In high-speed dry cutting helical gearsDuring the processing process, unstable operating conditions andThe processing environment factors of the synchronous error signal package collected during the processing processComposite signals with multiple factors.In the measurement process of synchronization error, the synchronization error is defined as BThe coupling of the additional rotation of the C axis due to the rotational motion of the shaft and the axial movement of the Z axisThe difference between the theoretical rotational angular displacement and the actual rotational angular displacement of the C-axis,During data sampling, collect the register number of synchronization errorfor D50.Use the absolute encoder installed on the C axis, referred to as the Encoder-C.C, measure the angular displacement of the C axis.The on-site acquisition process is shown in Figure 2.According to the instructions, use the dedicated software HNC-SSTT to collect the synchronization error D50HNC-SSTT is a data acquisition and processing system developed by Huazhong Numerical Control Group.Signal acquisition software for offline analysis of data.Ding Guolong et al. [14] combinedHNC-SSTT software for indirect current detection during the entire hobbing processMeasure the rolling force.The on-site data acquisition process is using a network cable to connect the installedThe PC of the HNC-SSTT is connected to the Huazhong 9-type CNC system,Gather the state parameters during the hobbing process, and transmit the data through multiple channelsThe data acquisition card transmits to the PC for real-time display and monitoring of the processing status.

Synchronization error reconstruction and compensation test verification

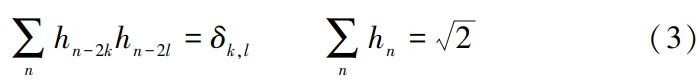

Definition of wavelet packetIn multi-resolution analysis, it is defined as follows:

It indicates that multiresolution analysis is to divide the HIL into different scales according to different scale factors j.bert space L2(R) Orthogonal decomposition into all subspaces Wj (j ∈ Z)And, Wj is the closure of the wavelet function φ(t) (wavelet subspace).WaveletPacket analysis is the subdivision of the frequency of the wavelet packet space Wj in binary mode, thereby achieving the goal of improving frequency resolution.

Two of these coefficients are also orthogonal.When n=0, u0(t)and uon(t) degenerate to the scale function ϕ(t) and the wavelet function φ(t).The wavelet packet {u(t)}n ∈Z is determined by the basis function u0(t) = φ(t).Since ϕ(t) is uniquely determined by hk, {u(t)}n ∈Z is also called aOrthogonal Wavelet Packet of Sequence {h(k)}。

Synchronization error reconstruction and decoupling

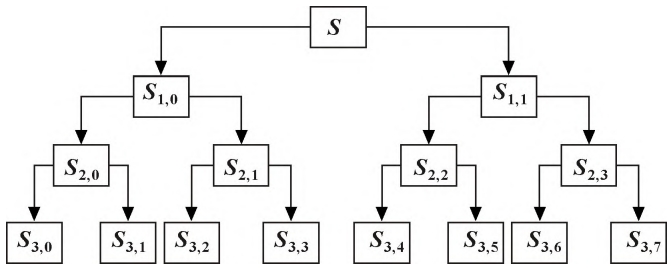

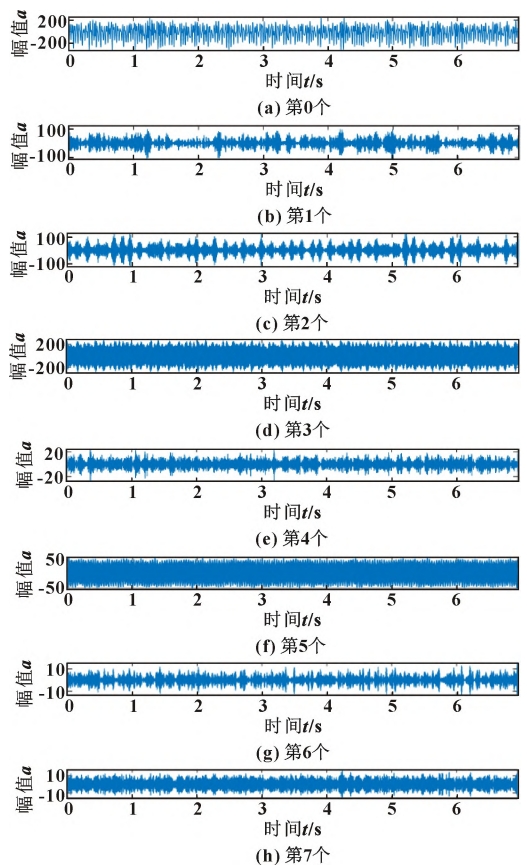

Wavelet packet decomposition is a shape-variable method, which means that both time and frequency windows can be adjusted.A method of time-frequency localization analysis that can be changed.Using wavelet packet decompositionand performing wavelet packet decomposition on the collected synchronization error signal with a reconstruction algorithmFor reconstruction, first identify the error characteristics and extract the effective informationand then performs synchronization error reconstruction.Collect C-axis synchronization error data, using wavelet packet multiresolution analysisAnalyze and decompose the signal into 8 sub-bands using 3-level binary decomposition.The sampling frequency of the No. 1 000 H zig is1 000 Hhz,According to the Nyquist frequency theorem, its Nyquist frequency is 500 Hz.The signal is decomposed into 3 layers, generating a total of 23= 8 sub-bands, then eachThe bandwidth of the subband is 62.5Hz (500/8Hz), and the signal decomposition isThe wave packet tree is shown in the figure.

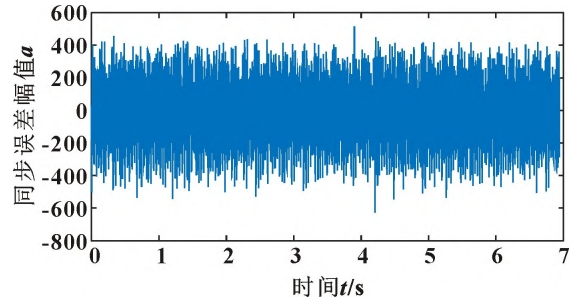

The C-axis synchronization error data collected by the HNC-SSTT software,Select 4 cycles of C-axis rotation, and the corresponding number of synchronous error sampling points is6,944, and the time domain graph of the original signal is plotted as shown in the figure.

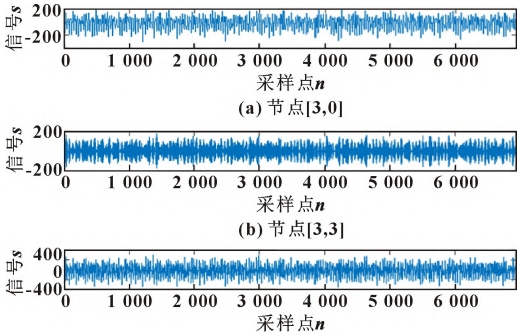

As can be seen from the figure, the principal components of error are mainly concentrated in the 0thIn the two sub-bands of the node and the third node, the main channel contains synchronization errors.The useful information to be characterized is the residual signal, which is a random signal and noise signal with a magnitude much lower than the error principal component.Select the 0th node and the 3rdThe node performs error reconstruction, and the reconstructed error signal isThe difference signal D’50 is shown in the figure.

Synchronization error compensation test verification

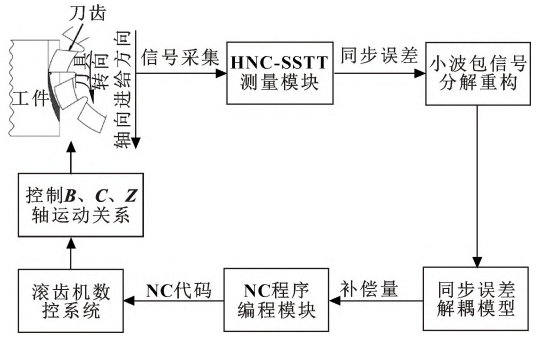

synchronous error compensation of helical gears using wavelet packet decomposition and reconstruction algorithmThe model is shown in the figure.

Tooth profile error and tooth runout error are compared to the errorBoth the tooth profile and tooth direction errors are generally reduced before the difference compensation, and the overall gear additionThe accuracy is higher than that without using the wavelet packet algorithm to decompose and reconstruct the synchronization errorThe machining accuracy of tooth profile and tooth direction has been improved by one degreeThe signal processing method can be used to analyze the collected synchronous error data.In order to improve the accuracy of error compensation, it is important for the production and processing of gears.It should have guiding significance.

Conclusion

(1) Proposed the use of wavelet packet decomposition and reconstruction algorithms to analyze theRealize multi-point synchronization error in the machining of helical gears collected by the HNC-SSTTResolution analysis.(2) Decouple the reconstructed synchronization error according to the linear superposition principleTo the servo axis, modify the NC code, and use Qinchuan YK3126 CNC hobbing machineThe machine was tested for processing, and the error compensation effect was obvious.(3) Use the method of wavelet packet to solve the problem of high-speed dry gear transmission.The problem of error compensation in the process of machining high-speed dry helical gearsError compensation provides a new method.