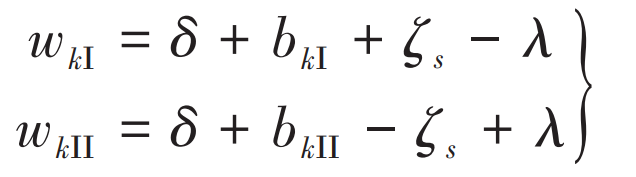

Due to the limitation of manufacturing difficulty and production cost, it is difficult to improve the transmission stability by improving the machining accuracy of parts in the actual machining process. Therefore, for the herringbone gear that has been processed and formed, only the debugging and assembly of the gear pair is considered, so that multiple error components can be effectively coupled and compensated, so as to improve the transmission stability of the herringbone gear system, so as to realize the compensation of herringbone gear alignment error more quickly and economically. Due to the overlap between alignment error and axial installation error, it is transformed into the error that affects the initial clearance of gear teeth during loading contact. At this time, the component of axial assembly error in meshing direction is introduced λ, The formula is converted to:

Reconstruct the displacement coordination equation of the gear, replace it into the formula, and re solve the calculation to obtain the load contact result of the herringbone gear after compensation.