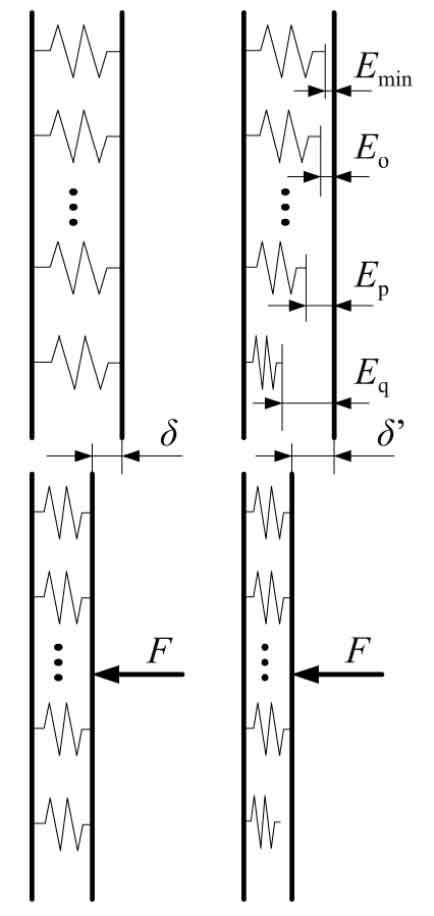

When the helical gear is an ideal tooth profile, assuming that there is no backlash between the gear pairs and the gear is not affected by the normal force F, the pairs of thin helical gear pairs along the meshing line of the helical gear should contact at the theoretical position; When the gear is subjected to the normal force F, the deformation of each thin helical gear pair along the normal direction is Δ j = δ Is equal, δ Is the transmission error when the helical gear pair is subjected to the normal force F, j is the number of each thin helical gear pair, (J ≤ 1,…, m), as shown in Fig.

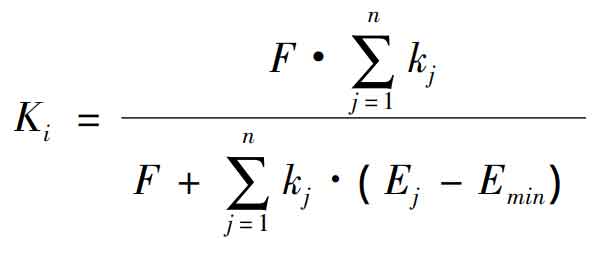

For the helical gear profile trimming, from the helical gear end face, the error after profile trimming is the same at the same meshing position, but the meshing position of each meshing point on the helical gear meshing line is different. Therefore, the meshing lines at different rotation positions are different, and the meshing position and meshing error are also changed. Suppose that the total tooth error of each slice helical gear pair is EJ (J ≤ 1,…, m) after profile trimming along the meshing line direction of the helical gear pair at a certain time, where EO, EP and EQ represent the tooth error of three pairs of slice helical gear pairs, and Emin represents the pair with the smallest total tooth error of n (n ≤ m) pairs of slice helical gear pairs participating in meshing at the moment. Combined with the above calculation method of helical gear meshing stiffness, the comprehensive meshing stiffness of Helical Gear Considering tooth profile trimming at any time can be obtained, and the expression is:

Where: F represents the normal force on the helical gear pair; N indicates that in this rotation position, n pairs of thin helical gears participate in meshing; KJ represents the meshing stiffness of the jth pair of thin helical gear pairs and specifies that when the teeth are not in contact δ J < 0, kJ = 0, EJ represents the total meshing error of the jth pair of thin slice helical gears, which is equal to the sum of the errors of the two meshing thin slice helical gears, and I represents the rotation position serial number.