The rigid-flexible coupling method in simulation is used to establish the simulation model of the hemispherical bevel gear system. The design parameters of the hemispherical bevel gear pair are shown in the table.

| Number of teeth z | 12 |

| Normal pressure angle α (/ °) | 20 |

| Addendum height coefficient | 1 |

| Coefficient of top clearance | 0.25 |

| Pitch radius rp/mm | 25~40 |

| Pitch angle β (/ °) | 0~80 |

| Material Science | structural steel |

| Elastic modulus (/N · mm-2) | 2.1 × 10^11 |

| Poisson’s ratio | 0.3 |

| Output load torque (/N · m) | 50~500 |

| Contact stiffness (/N · mm-1 5) | 7.2 × 10^5 |

| Input speed (/r/min) | 60 |

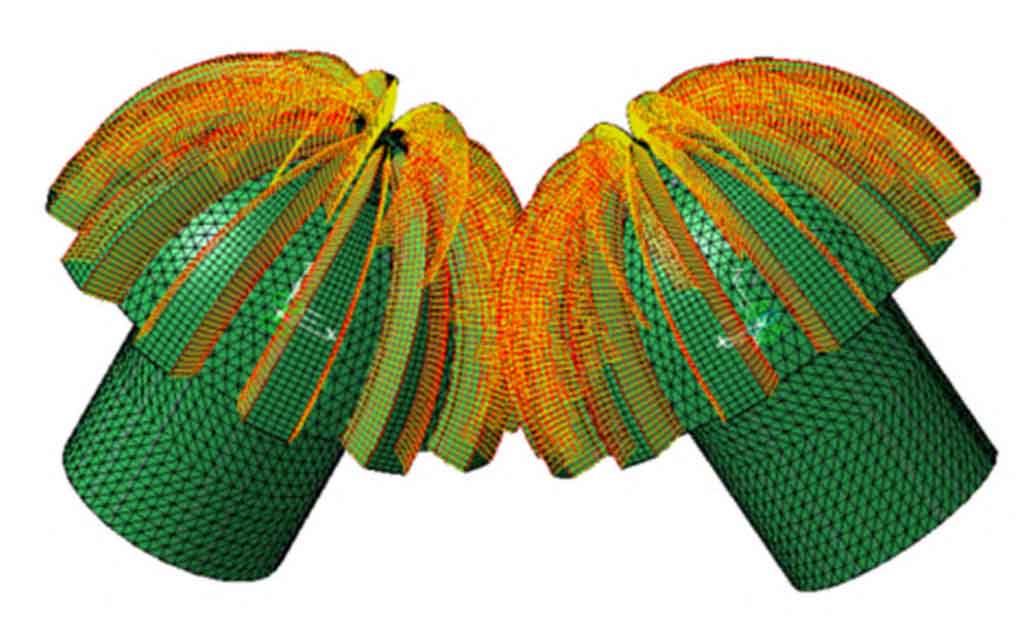

Flexible to import mesh files. Define the non-contact mesh as a tetrahedral element with a size of 2 mm; Refine the mesh of the arc-shaped tooth surface and the tooth root part participating in the meshing, and set its mesh as a hexahedron unit with a size of 1 mm. Set solution parameters for model simulation. The final rigid-flexible coupling structure of the hemispherical bevel gear pair model is shown in the figure.