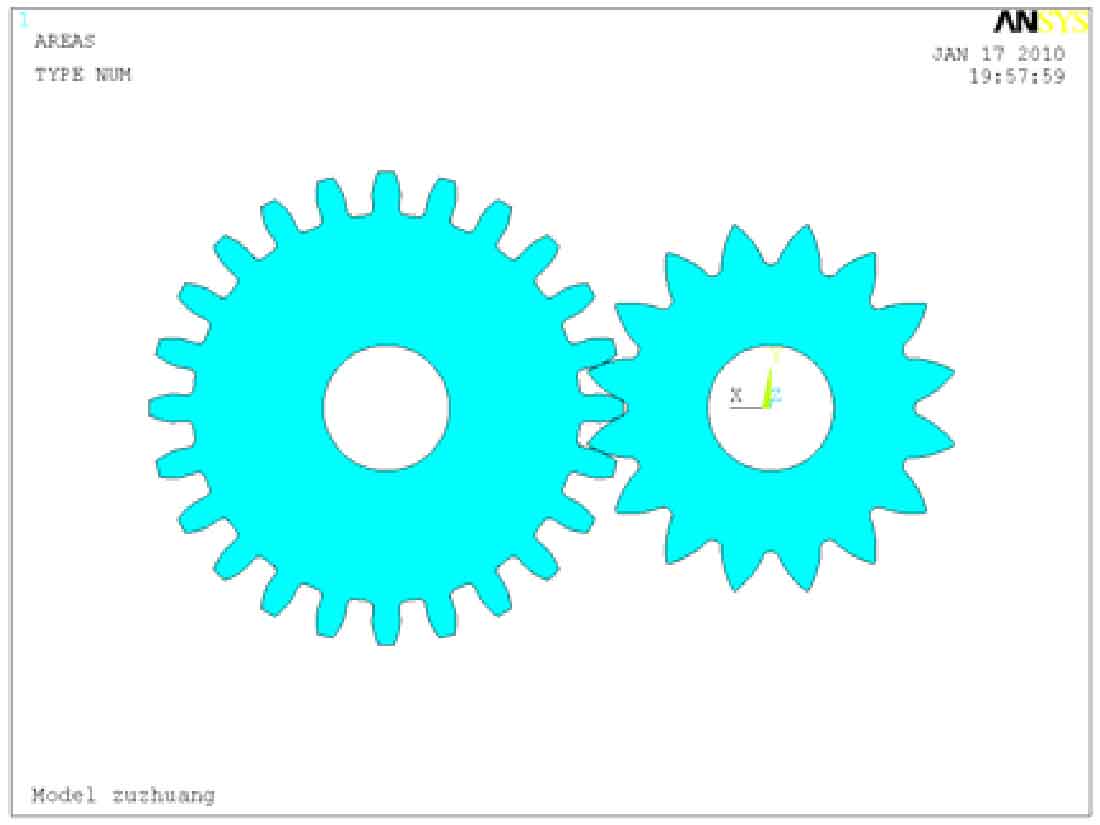

Using the advanced curve drawing function in the two-dimensional drawing software CAXA electronic Using the advanced curve drawing function in the two-dimensional drawing software CAXA electronic drawing board, draw the peripheral contour of the spur gear, assemble the large and small gears, and then import it into ANSYS to build the spur gear solid model; Using the solid modeling function in the pre processor of ANSYS, that is, the function of generating a plane from a line, the contour lines of two spur gears are formed into two spur gear planes to generate a two-dimensional solid model for spur gear contact analysis, as shown in Figure 1.

The principle of meshing is to refine the key parts of the model locally under the condition of ensuring The principle of meshing is to refine the key parts of the model locally under the condition of ensuring sufficient calculation accuracy, so as to achieve sufficient analysis accuracy, and minimize the number of overall meshes of the model to save calculation time. The selection of solid elements of two-dimensional structure of large and small gears is plane182, which is divided by free mesh to form quadrilateral mesh. This paper mainly analyzes the equivalent stress of spur gear tooth surface contact and its contact stress. Therefore, the intelligent grid division function is adopted for control to automatically encrypt the grid at the spur gear contact line, so as to ensure the accuracy of calculation. The precision is smart size = 3. The finite element model after meshing is shown in Figure 2.