Different gear processing methods form the micro complex morphological characteristics of spiral bevel gear tooth surface, which brings difficulties to the evaluation of spiral bevel gear tooth surface roughness. The reason is:

- The application of spiral bevel gear tooth surface finishing technology is not universal;

- People’s evaluation of the tooth surface roughness of spiral bevel gear is not unified, the analysis methods are different, and the understanding of Chinese national standards is also very inconsistent, resulting in the deviation between the judgment of the tooth surface roughness grade of spiral bevel gear and the actual situation.

Due to the complex topological structure of spiral bevel gear tooth surface, it is difficult to find the datum line for measuring the sampling length of tooth surface roughness (the plane sampling length datum line is a straight line, and the cylindrical gear sampling length datum line is an involute). Therefore, the traditional contour arithmetic mean deviation ra and the ten point height RZ of micro unevenness cannot be measured, but the RA formula can be extended to solve it.

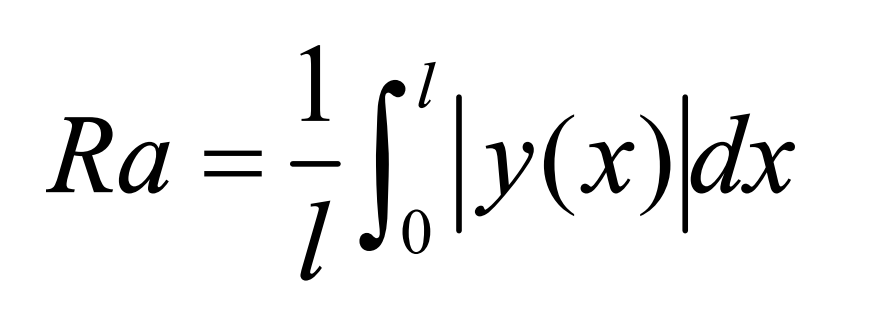

From the definition of RA:

Where:

RA — arithmetic mean deviation of contour

L – Sampling Length

Y (x) – Sampling curve measured on the sampling length

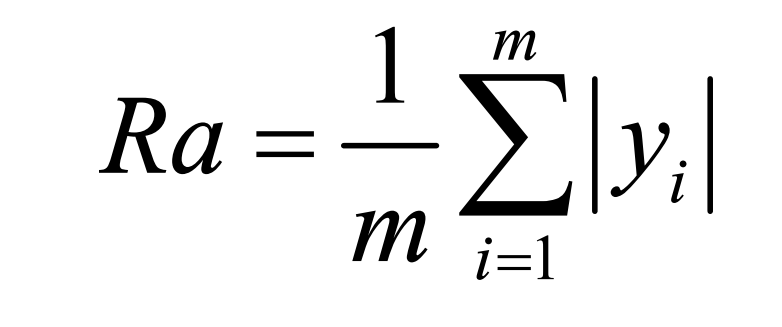

In practical use, the formula can be approximately as follows:

Where:

M — number of sampling points measured on the sampling length

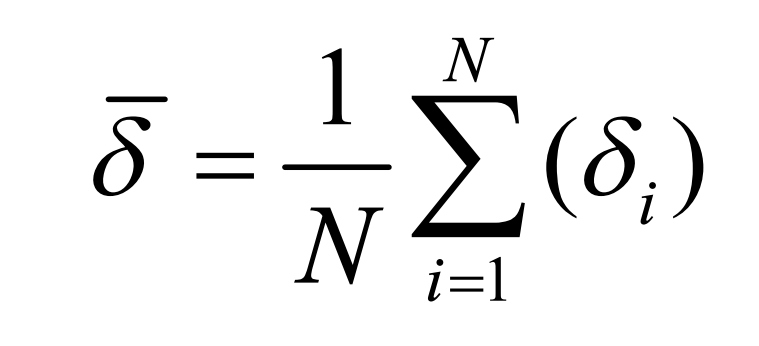

The analysis shows that on the tooth surface of spiral bevel gear, the residual height of knife grain is wave crest, and the theoretical residual height is δ i. The residual height at the contact point between the cutting edge and the pinion tooth surface is the trough, and the theoretical residual height is 0. Therefore, the average residual height of spiral bevel gear tooth surface can be expressed as:

Where:

N — number of calculation points of residual height on tooth surface

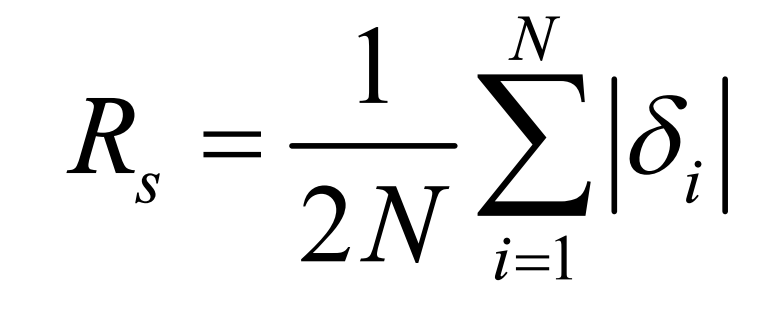

The tooth surface roughness of spiral bevel gear can be approximately expressed as: