In order to verify the machining accuracy of the studied process, taking the machining of large module cylindrical gear as an example, an example is verified and analyzed.

1. Cylindrical gear design scheme

The gear to be processed in this paper is a large module cylindrical gear. The design scheme of the cylindrical gear is shown in Table 1.

| Name | Parameter value |

| Number of teeth | 24 |

| Modulus / mm | 12 |

| Pressure angle / (°) | 20 |

| Root circle diameter / mm | 20 |

| Tooth root height / mm | 40 |

| Addendum circle diameter / mm | 40 |

| Tooth crest height / mm | 80 |

| Pitch / mm | 270 |

| Tooth width / mm | 71 |

| Tooth height coefficient | 1 |

| Top clearance coefficient | 0.25 |

| Displacement coefficient | 0 |

2. Selection of manufacturing materials for cylindrical gears

20CrMoTi carbon steel with hardness of 32 ~ 40 HRC is selected as the processing and manufacturing material of the target cylindrical gear, and its material mass fraction is shown in Table 2.

| Ingredients | C | Mn | Si | Cr | Ti | Mo |

| Proportion | 0.17~0.24 | 0.40~0.70 | 0.17~0.37 | 0.80~1.10 | 0.04~0.10 | 0.15~0.25 |

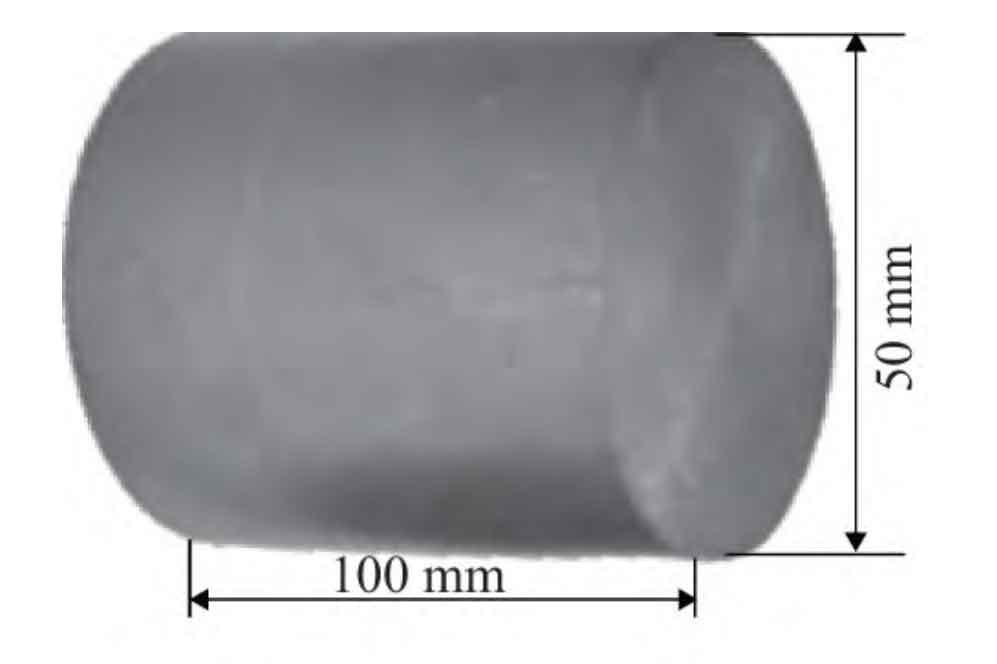

3. Forging and blank making

20CrMoTi carbon steel is used as raw material for forging to form a cylindrical gear blank, as shown in the figure.

4. Design of heat treatment scheme

Heat treatment was carried out on the carbon steel cylindrical gear blank of Fig. 20CrMoTi to improve the quality of cylindrical gear blank. The heat treatment scheme is quenching + tempering scheme, and the specific parameters are shown in Table 3.

| Name | Parameter value |

| Heating temperature of the first quenching / ℃ | 860~ 880 |

| Heating temperature of the second quenching / ℃ | 860~ 880 |

| Quenching coolant | Water and oil |

| Tempering heating temperature / ℃ | 620~ 650 |

| Tempering holding time / min | >240 |

| Tempering coolant | Air, oil |

5. NC machine tool processing scheme

Select the combination scheme of gear milling and gear grinding to process and manufacture cylindrical gears. Firstly, rough machining is carried out by gear milling CNC machine tool, and then fine machining is carried out by gear milling CNC machine tool. The selected CNC machine tools are cak6136c gear milling CNC machine tool and hoffler rapid2000 gear grinding CNC machine tool. The former adopts Mechatronics structure, applies three-dimensional design software for optimization design, and carries out finite element analysis, so as to make the structural design of the machine tool more reasonable and the rigidity, accuracy retention and reliability of the machine tool more perfect. The latter is designed for medium and large-scale precision and complex parts, with the characteristics of high precision and high performance. Equipped with the original gear power shaft, it can carry out the compound processing of cylindrical gears with high precision and high efficiency.