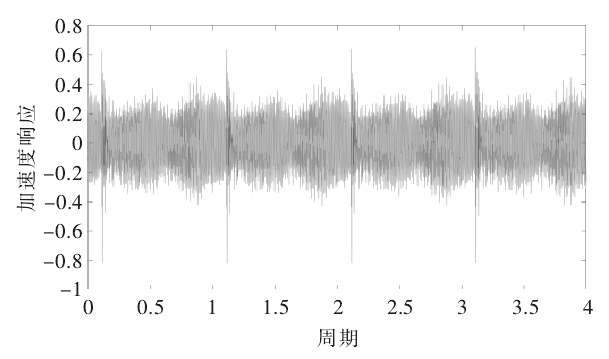

Take the detection of high-speed shaft gear as an example. The sensor data of high-speed shaft bearing position is taken as the original data to detect the large gear part of high-speed shaft. The time domain vibration response signal is shown in Figure 1, and the periodic domain data obtained after preprocessing is shown in Figure 2.

As can be seen from Figure 2, the data has 96 cycles, which is consistent with the number of cycles set.

The signal is processed by synchronous average method, which strengthens the periodic component synchronized with the shaft rotation, removes other non periodic components and periodic components not synchronized with the shaft rotation frequency pulse, and greatly improves the signal-to-noise ratio.

In order to verify that the processed periodic domain signal contains the operation information of the components with the same speed as the specified shaft, the synchronous average analysis method is used for analysis, and the results are shown in Figure 3.

From Figure 3, we can observe the periodic shock pulse, suspected abnormal response signal.

The signal averaged in the period domain contains the characteristic information of gear fault, and then the frequency analysis can effectively detect the gearbox fault. Carry out spectrum analysis on the signal after synchronous average analysis, i.e. synchronous average order spectrum analysis, and the results are shown in Figure 4.

As can be seen from Fig. 4, the order difference of the sidelobe of meshing frequency 102 and its frequency doubling is 1.

Combined with the results of signal synchronous average analysis in periodic domain, it is preliminarily judged that the high-speed big gear may be damaged. The results of this analysis are consistent with the results of endoscopic detection of wind field. Therefore, using the improved data preprocessing method for data reduction, the periodic domain signal obtained can find the damage of transmission chain components, and the improved data preprocessing method can be used for fan condition monitoring.