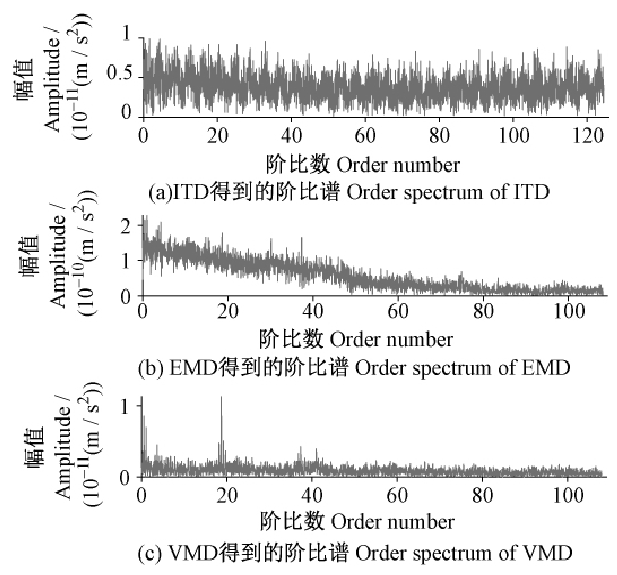

In order to further illustrate the superiority of this method, the order spectrum obtained by EMD and itd is compared

It can be seen from Figure 1 that there are many interference factors in the order spectrum of broken tooth fault obtained by ITD method, which is more prominent only at the double meshing order, but the fault information can not be obtained; the method based on EMD can obtain clearer fault information, but the noise interference is heavy, which has a significant impact on the accurate judgment of fault information; The results show that the method based on VMD has the best effect, the least noise interference and the prominent spectrum peak, which can accurately extract fault information and carry out effective fault diagnosis.

It can be seen from Figure 2 that the fault information can not be effectively extracted by ITD and EMD methods because the fault features of uniform wear are not obvious, while VMD method can better identify the fault and effectively extract the order signal of fault features.

The comparison shows that the VMD method can effectively reduce the noise interference and enhance the accuracy of fault feature extraction. It is proved that the gearbox fault feature extraction method based on VMD order tracking is superior.