1. Closed power flow herringbone gear test bench

Compared with the traditional open power flow test-bed, the closed power flow test-bed used in this experiment is more energy-saving. Closed power flow means that the route of energy transmission forms a closed loop in the entire test bench. The inverter system converts part of the energy consumed by the loading equipment into electrical energy, and then transmits it back to the drive system to achieve the effect of loading and energy saving. The vibration speed sensor model is CYT9200, the measurement range is 0 ~ 50mm · s ^ – 1, and the system sampling frequency is 2000Hz.

The layout of the test bench is shown in Figure 1. During the test and measurement, the sensor is tested at three measuring points of 90 °, 180 ° and 270 ° in the axial direction of the input shaft.

2. Verification and analysis of test results

The vibration speed of herringbone gear at different speeds and torques is measured by the test bench. Take time as the abscissa and the vibration speed along the Z direction on the right side of the pinion as the ordinate to obtain the comparison diagram of the vibration speed of the three measuring points.

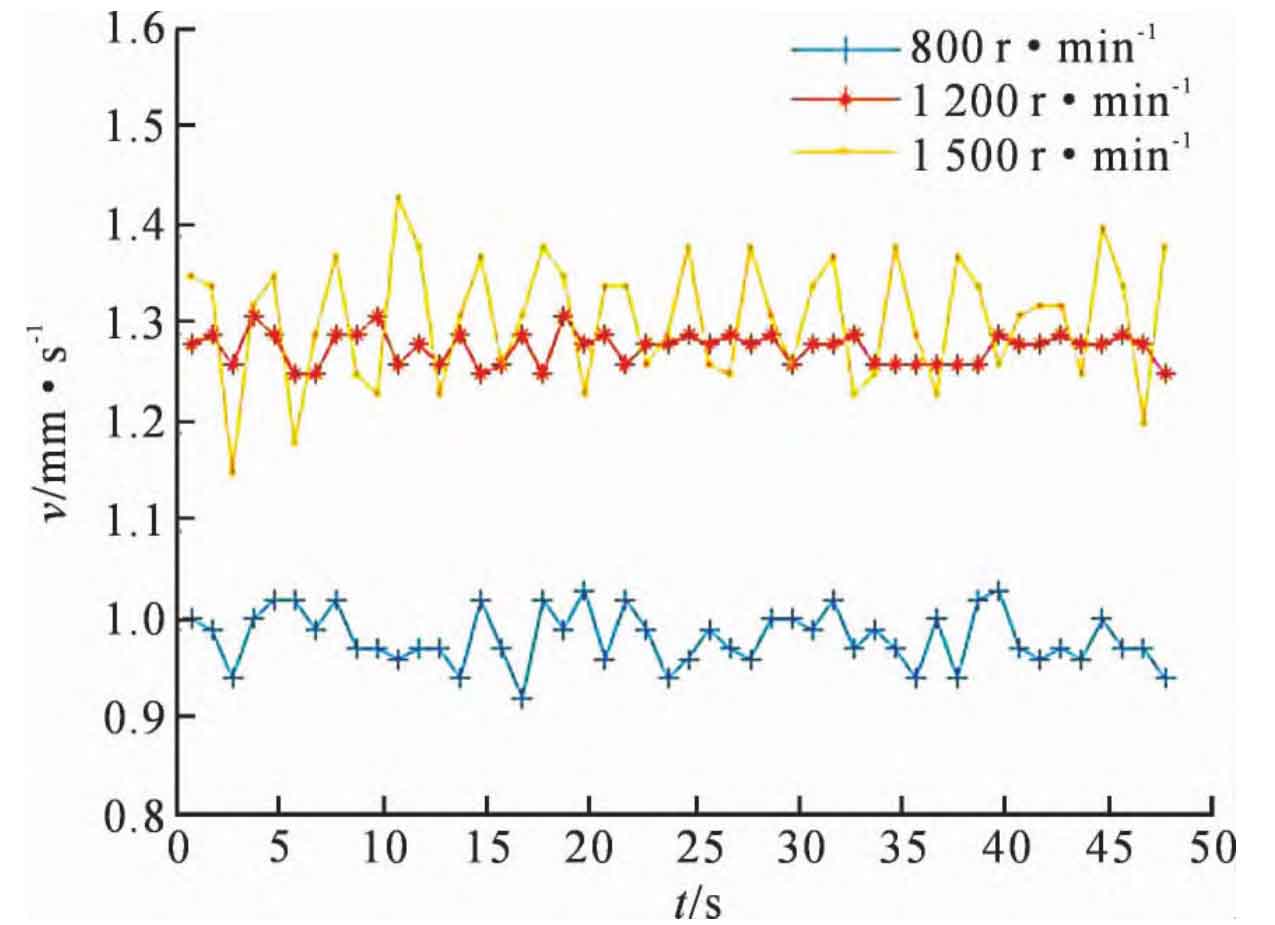

Fig. 2 shows the axial vibration speed of herringbone gear at speeds of 800r · min ^ – 1 and 1200r · min ^ – 11500r · min ^ – 1 respectively. It can be seen that when the measuring point and torque remain unchanged, the increase of speed leads to the increase of vibration speed; Also at 1500r · min ^ – 1, it is obvious that the axial vibration velocity fluctuation of herringbone gear is greater than that of other two cases.

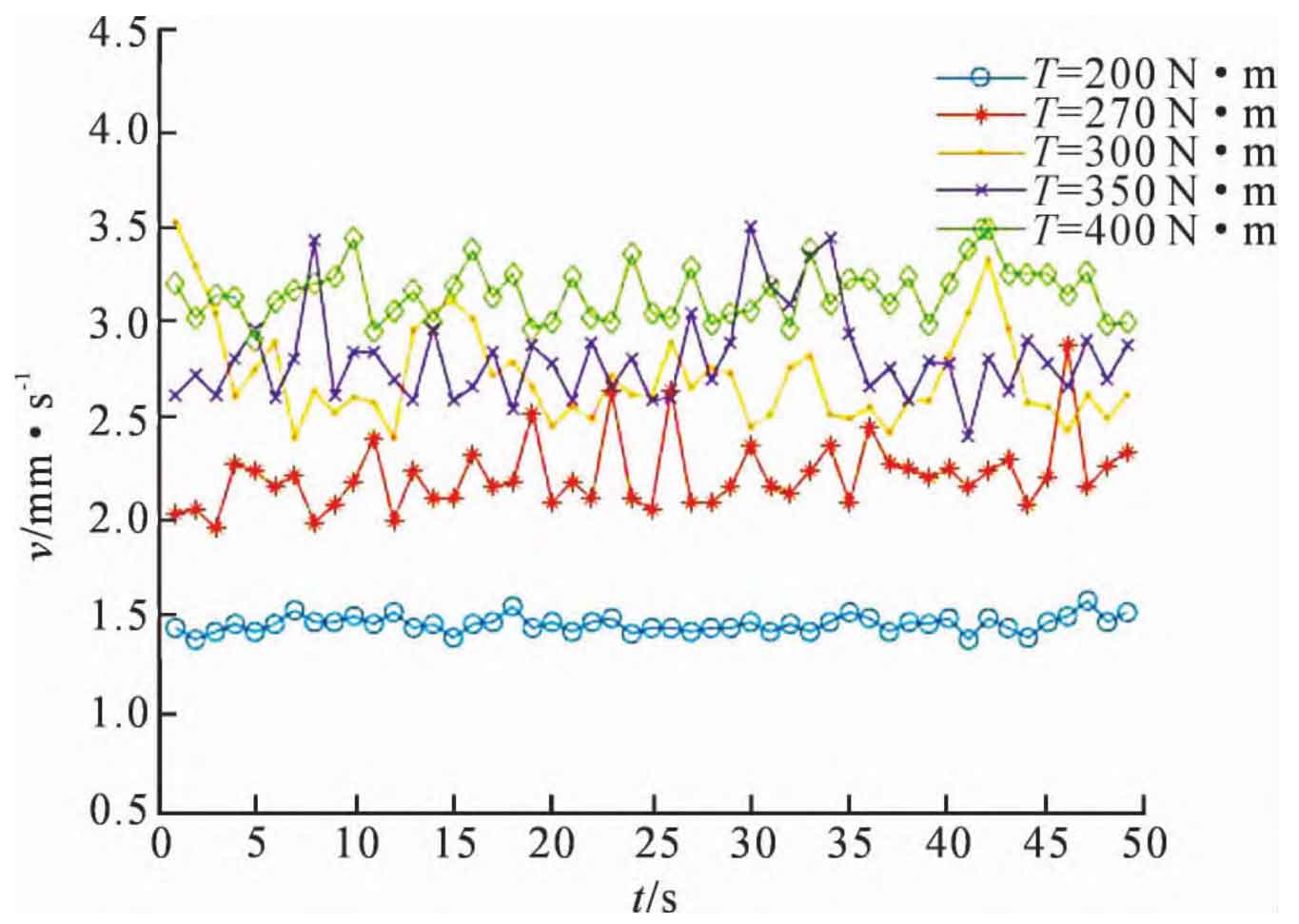

Fig. 3 shows the comparison diagram of axial vibration speed of herringbone gear under different torque conditions when the speed is 1000r · min ^ – 1. It can be seen that the increase of torque will lead to the increase of vibration speed when the measuring point and speed are unchanged; At the same time, when the torque is large, the axial vibration speed of herringbone gear fluctuates greatly.

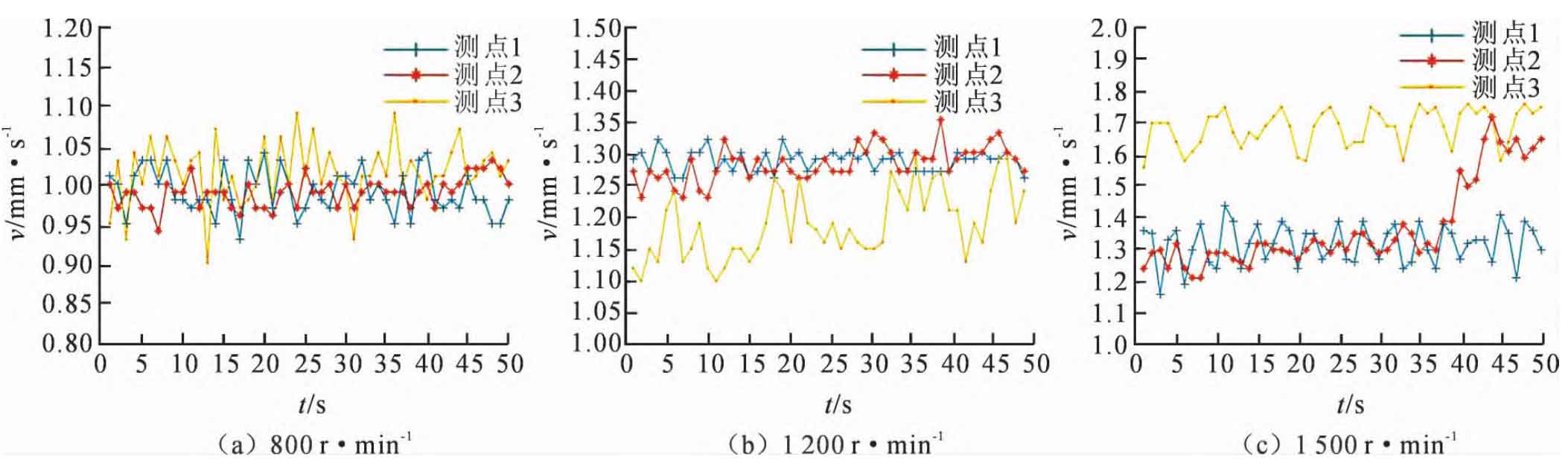

Fig. 4 shows the comparison diagram of axial vibration velocity of herringbone gear at 800r · min ^ – 11200r · min ^ – 11500r · min ^ – 1. The variation law of the moving vibration speed of the measuring point is obtained under the condition that the speed and torque are constant. When the rotating speed is 800r · min ^ – 1 and 1200r · min ^ – 1, the vibration speed of the three measuring points changes little, but when the rotating speed reaches 1500r · min ^ – 1, it is obvious that the vibration speed gradually increases with the change of the measuring point position, showing the influence of symmetry deviation on the axial vibration of herringbone gear.