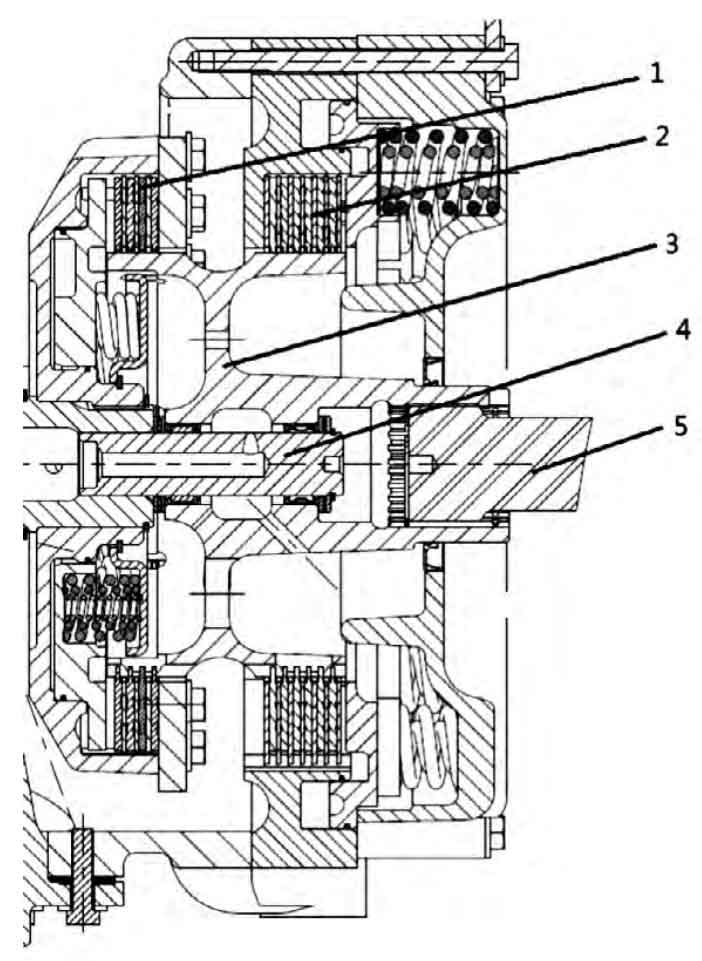

The central transmission structure of the bulldozer developed by a company is shown in Figure 1. When the whole machine works for 800 ~ 1000 hours, it is found that the single track does not move and cannot turn.

After disassembling the central drive, it is found that the output spline of the gear hub is broken, and the fault picture is shown in Figure 2. For this problem, the reason for the fracture of the output spline of the gear hub is analyzed.

The power is transmitted from the gearbox to the central transmission. According to the driving situation, the corresponding clutch in the central transmission works, and the power is output to the final transmission to realize the required straight travel, left turn, right turn and braking. Before power is input to the final drive, it needs to pass through the gear hub and output shaft, so the splines of the gear hub and output shaft play an important role in force transmission.

In the central transmission of bulldozer, the gear hub plays an important role in power transmission and is the last part of the central transmission power transmission. Once the gear hub is broken, the power of the whole machine cannot be input to the wheel edge. At least, the power is insufficient or it is unable to walk and turn. At worst, the debris mixed with oil enters the valve, resulting in the paralysis of the whole machine. Directly affect customers’ use and satisfaction with the whole machine.

Therefore, we need to analyze the failure causes of gear hub parts and optimize the design, so that its strength can better meet various working conditions of bulldozer.

By analyzing the fracture morphology and metallographic structure, taking effective technical improvement measures and improving the stability of heat treatment process, the reliability of gear hub is further improved, the fatigue fracture problem of improved gear hub is solved, and the quality of the whole machine is improved. At the same time, the research can be widely applied to loaders, bulldozers and other construction machinery.